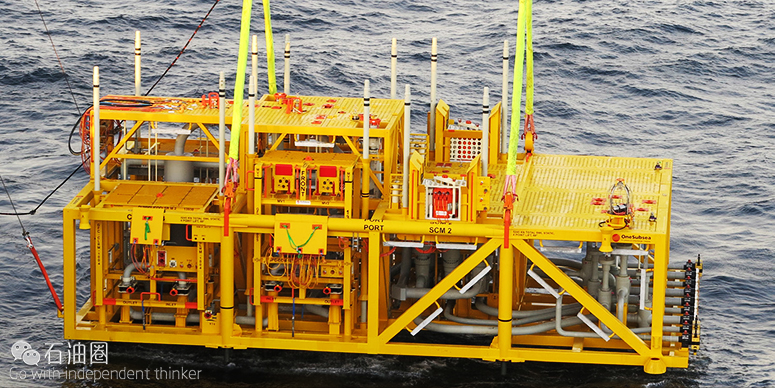

OneSubsea has delivered the world’s first subsea Multiphase Compressor to Statoil for the Gullfaks South field in the North Sea.

The subsea multiphase compressor enables boosting of unprocessed wet gas production fluids, while eliminating the need for an upstream separation facility or an anti-surge system, making it the industry’s only true wet gas compressor. It is expected to increase the recovery rate for the Gullfaks South Brent reservoir by 22 million barrels of oil equivalent.

OneSubsea Chief Executive Officer Mike Garding said, “Statoil is at the forefront of subsea compression. By working in collaboration with Statoil, we have been able to develop an optimal solution to help them advance their subsea factory strategy.”

The OneSubsea Multiphase Compressor, a 2015 OTC Spotlight on New Technology Award winner, is the world’s first and only true subsea wet gas compressor with no requirements for an upstream separation facility or an anti-surge system, which greatly simplifies the subsea system requirements. The compressor is a contra-rotating machine specifically designed for pressure boosting of unprocessed wellstream. This unique configuration, developed in collaboration with Statoil and Shell, allows for a compact and robust design that is easy to install by use of light intervention vessels, and is based on the well-proven design developed for subsea booster pumps.

The subsea multiphase compressor is capable of handling high liquid contents without mechanical issues, with gas volume fractions typically in the range of 95% to 100%. This compressor represents a breakthrough in the subsea environment as it enables compression of the unprocessed wellstream without any need for pre-processing. This will enable deployment of simplified subsea systems at lower capital expenditures and field development costs.

The main driver in the development of the multiphase compressor was to increase recovery rates and to cost-effectively increase the tieback distances of subsea gas fields. The Gullfaks field, operated by Statoil and located in the North Sea, will see the first commercial deployment in the world for subsea wet gas compression. Statoil foresees that the recovery rate will increase by 22 million barrels of oil equivalent, by using the wet gas compression system. The wet gas compression station for Gullfaks will be installed approximately 15 km away from the Gullfaks C platform; commissioning is planned for 2015.

Some key advantages of the multiphase compressor, which enables cost-efficiencies and significantly improved operational performance, include:

- Continuous operation on all liquid fractions (0 – 100%);

- Operates in all flow regimes;

- Standard fluid film bearing technology;

- Surge-free operation so no anti-surge system is required;

- Sand and solid tolerant design;

- Low speed allow for long step-out without subsea VSDs;

- Low module weight (approx. 60 t) allow for light vessel intervention.

World’s First Subsea Multiphase Compression System Installed in Norwegian North Sea

Statoil wanted to enhance recovery from maturing asset

As field development matures, natural reservoir pressure declines, slowing production and reducing ultimate recovery. Anticipating this natural phenomenon, Statoil required a solution that would help generate enough pressure to maintain production from the South Brent reservoir in the Gullfaks South field, thus increasing recovery of the large volume of gas remaining in the reservoir.

Subsea compression can accelerate production, increase recovery, and manage flow-related challenges in a cost-effective manner. It is energy efficient because the compression system is located close to the reservoir. The reduced weight and space requirements topside result in further cost benefits.

Moreover, a subsea solution would serve as an important advancement in the development of the subsea factory and was therefore preferred.

OneSubsea developed world’s first subsea multiphase wet gas compressor

Following a study phase with several industry suppliers, Statoil awarded the contract for development of the world’s first subsea multiphase compressor to OneSubsea in 2009. In close collaboration with Statoil, a team of experienced engineers began working on a system that would operate as effectively and reliably as the market-leading subsea boosting technology—with an accumulated run time exceeding 2.6 million hours by the end of 2015—from OneSubsea, while achieving the customer-defined goal of an extended production plateau and higher recovery factor.

A state-of-the-art hydrocarbon test loop was built to ensure that the hydraulic performance of the proposed system could be verified by an extensive test program. The high-pressure loop was designed to run live hydrocarbons at flow rates of approximately 400 MMscf/d at 65 bar [6.5 MPa] and up to 284 degF [140 degC]. The performance mapping in the flow loop comprised approximately 900 test points and overall machine run time of more than 4,500 hours.

Estimates indicated additional recovery of 22 million barrels of oil equivalent

After comprehensive and successful testing, the WGC4000* multiphase compressor was approved by Statoil. The contra-rotating machine is specifically designed to boost the pressure of an unprocessed well stream by 30–60 bar [3–6 MPa]. The compact and robust design does not require an upstream separation facility or an antisurge system, greatly simplifying subsea system requirements. It can handle gas/liquid ratios ranging from 0 to 100 and is easily installed using light well intervention vessels.

The WGC4000 compressor weighs less and occupies less space than topside compression solutions and can accommodate tieback distances of up to 62 mi [100 km], providing a cost-effective method of increasing recovery. Startup of the compressor was initiated in Q3 2015. Statoil estimates the multiphase compressor will help increase recovery from Gullfaks South field by 22 million barrels of oil equivalent.

石油圈

石油圈