光纤传感技术代表了油井监测的未来,光纤传感先进技术可以提供完整、实时的井底情况且不干扰油井作业。光纤安装到井中,作业者不再需要传统的生产测井、示踪剂测井或VSP测井的地震检波器等。现在,一根光纤获得的多重诊断结果,可以帮助降低作业风险减少作业费用。

PINNACLE是哈里伯顿公司专业从事油藏与压裂监测的部门,是光纤产品开发与应用行业领导者。该团队研发的光纤监测系统包括一系列分布式和散点式的传感器,可实现从非常规成熟油田市场到高温稠油的深水环境的井筒评估。石油圈原创www.oilsns.com

FiberWatch 具有分布式测温和声波传感系统,可提供整个油井生命周期的流体活动情况;FiberPoint™传感器可提供精确的井筒内压力和温度测量值,优化对流体运动情况的评估;与永久型泵浦光纤程序类似,SPECTRUM SM诊断服务和FiberPoint™检索服务都具有光纤传输的独特优势,可适应任何井下应用程序的需求。

FiberPoint 传感器石油圈原创www.oilsns.com

FiberPoint传感器是被设计应用于地球 上最恶劣环境下的最精密的测量工具。不同于传统的传感器,FiberPoint传感器没有内部电子元器件,而后者在恶劣环境下极易损坏。因此,FiberPoint开启了更大范围井底环境测量的新可能。FiberPoint SolarOptic传感器能够精确地测量温度与压力这两个对作业者来说最关键的信息。另外,Pinnacle正努力开发其他的FiberPoint传感器以便为井底测量创造新的机会,包括化学传感器、三分 量地震检波器及倾斜仪等等。

SensorTran光纤问答机石油圈原创www.oilsns.com

光纤与光缆是光缆绳系统的两个重要组成部分,但是激光问答机才是运行和分析真正发生的地方。问答机发送一个脉冲激光到光纤中,然后记录反射到问答机中的反向散射光的数量及类型。通过复杂的软件计算方法,这些反向散射光被转化为测量数据。SensorTran使用的不是电信系统的激光发生器,而是特别的单波长或多波长激光发生器,生成应用在油气井监测中所需要的特殊波长。

当作业者想要确保长期的监测作业而不用去考虑诸如弯曲损失或氢损等有害作用而导致的衰减影响时,PINNACLE双激光问答机可以帮助实现这个目标。哈里伯顿的专利技术PerfectVersion双激光系统利用特殊的激光波长自动补偿氢损导致的衰减。PerfectVersion系统可以在Gemini及Neptune DTS问答机中使用。

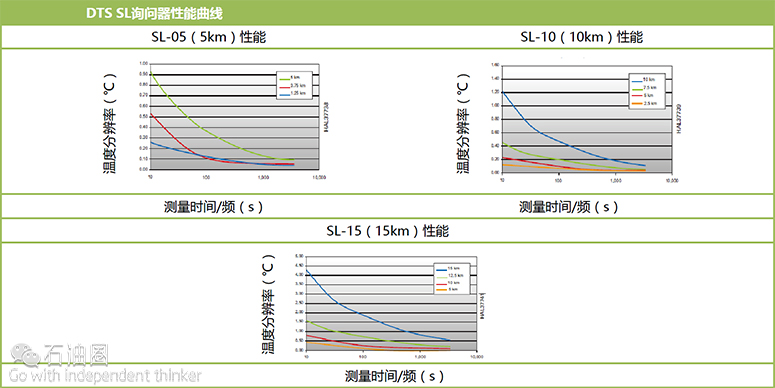

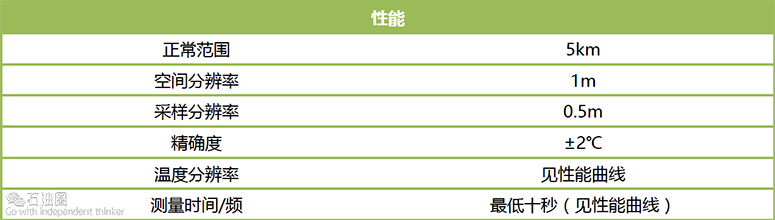

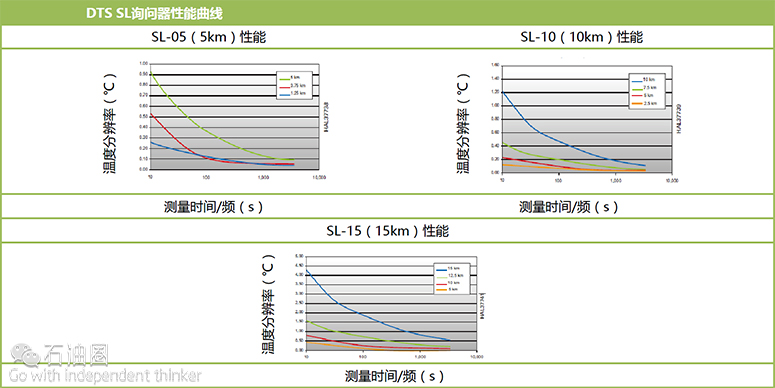

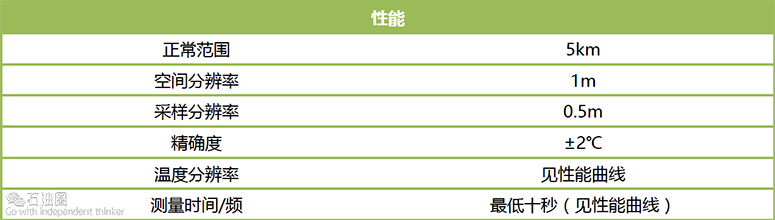

FiberWatch DTS单激光器(SL)系统

在全球部署的一系列测试验证证明,FiberWatch DTS单激光器(SL)系统可在任何环境中工作。单激光系统已成为一种高效的温度传感器数据收集工具,工作范围可达15km。

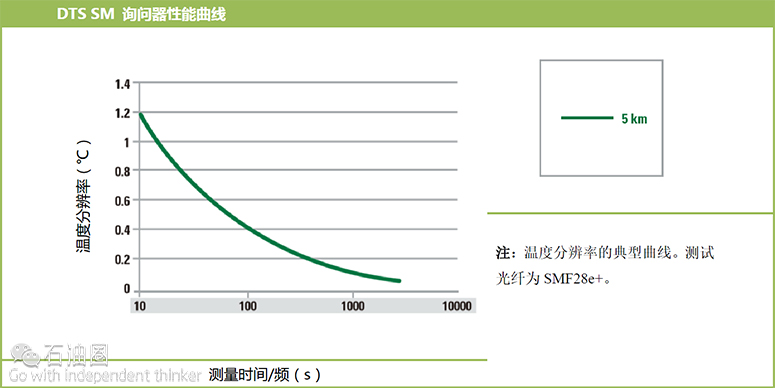

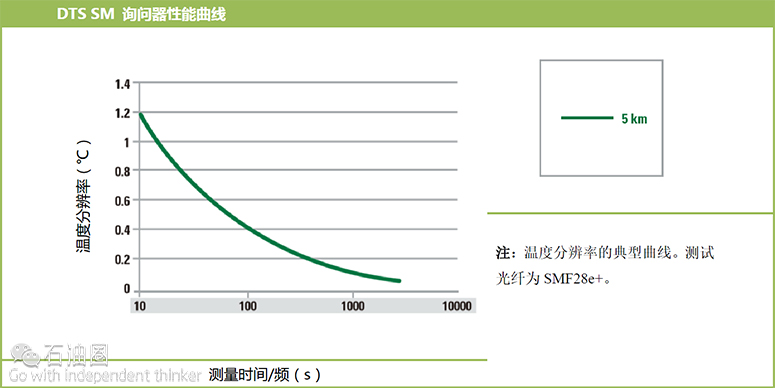

FiberWatch DTS单模(SM)系统石油圈原创www.oilsns.com

FiberWatch DTS单模(SM)系统用于特殊的单模光纤提供分布式温度传感数据。该方案适用于所有非常规、成熟油田、稠油和海上油田,利用双重激光技术,可减轻光纤退化的影响,消除了以往对双端测量的依赖。

StimWatch增产改造实时监测

StimWatch是PINNACLE注液剖面分析服务。通过监测井的温度分布,运营商能够准确地识别液体在井筒的什么位置进入地层。这对于多段完井非常有帮助,作业者可以据此判断是否所有目的层都被改造到。StimWatch拥有其他任何系统都没有的优势:

- 优化施工效果:对液体分布的认识 可以帮助作业者了解如何提升完井效率及施工设计;

- 提高经济性:准确了解裂缝起裂位 置可以帮助作业者对施工做出相应的调整,使液体转移到未被改造到的储层区域;

- 降低作业风险:实时信息使作业者 能及时发现封隔器、桥塞或尾管悬挂器的故障,并在继续施工前采取维修措施。

FlowWatch实时生产监测石油圈原创www.oilsns.com

FlowWatch监测与诊断服务利用分布式光纤监测生产期间的全井动态信息,帮助作业者识别各层产量、监测人工举升、发现油管内结垢或沉积等问题来了解井的生产情况。该技术能够准确地将井底的温度及声波变化与每一层液体和气体的产出位置与产量相关联,为作业者对井的产量、完井效果、油藏丰度等做出关键决定时提供坚实的基础数据。

- 确定各层产量:了解各层段的产量贡献,如各层油气日产量,确定见水位置及产水 量等,使作业者能够将其与施工设计、地质与储藏属性等关联起来;

- 提高经济性:光纤能够嵌入到油管中以获取生产剖面信息。可回收式光纤服务不需要修井钻台即可操作,大幅地降低了获得生产测井数据所需的综合费用;

- 监测井的动态:随着储层衰竭,或者当井部署人工升举系统时,产量如何变化呢?利用DTS,作业者可以确定这口井生产周期内的流体力学、各层产量贡献、流体相位改变等信息;

- 提高蒸汽利用效率:实时监测SAGD及CSS井蒸汽驱动情况及盖层完整性等,优化 采收率、提高蒸汽利用效率;

- 其他:确定层间窜流、预警定位窜水位置、实时监测固井质量、确定封隔器效果、 识别井下工具工作情况。

分布式感应

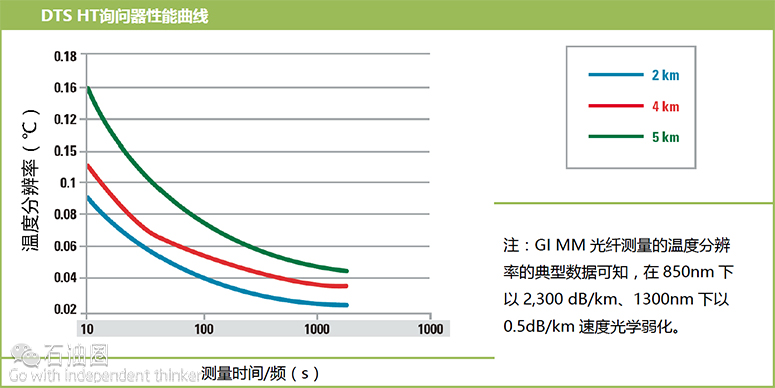

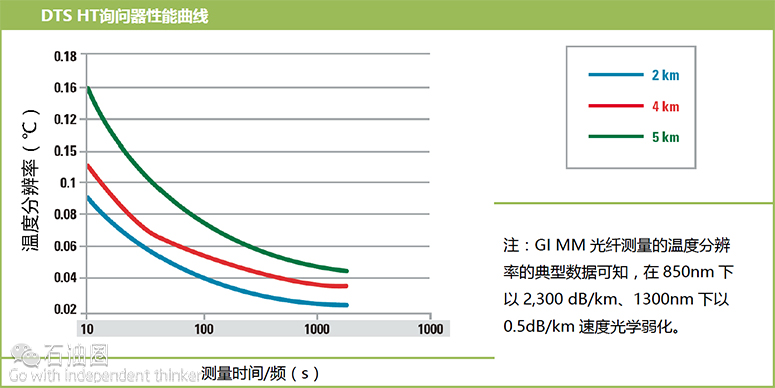

FiberWatch DTS耐氢系统(DTS HT)

FiberWatch DTS耐氢系统可在恶劣的上游环境中提供数据传输结果。该系统具有双重激光专利技术,双模光纤可减轻光纤退化的影响,提高使用寿命,获取更多有意义的数据。询问器则用于油井性能评估的长期监测。石油圈原创www.oilsns.com

FiberWatch分布式声波传感系统(DAS)

Halliburton公司已成功在全球上千口井部署光纤,并在非常规油田、成熟油田、高温稠油等各种复杂环境下为客户提供了重要信息。FiberWatch分布式声波传感系统(DAS)基于瑞利散射原理,实现长距离声波应变信号的确定。数据被获取后,在频率过滤、时间和深度域叠加等技术的辅助下,即可应用于各种各样的应用程序。

(注:瑞利散射原理,又称“分子散射”。粒子尺度远小于入射光波长时,其各方向上的散射光强度是不一样的,该强度与入射光的波长四次方成反比,这种现象称为瑞利散射。)

应用范围石油圈原创www.oilsns.com

- StimWatch注入流量剖析;

- FlowWatch生产流量剖析;

- 检漏/井筒完整性监控;

- 井间分析。石油圈原创www.oilsns.com

技术优势

- 实时数据分析;石油圈原创www.oilsns.com

- 强大的油田备用单元;

- FiberView可视化软件。

小编手中还握有光纤监测相关产品更多资料哦,想获取?很简单:请将此文章分享至朋友圈,发送截图和邮箱地址至石油圈微信后台。小编会将资料打包奉上,发送至您的邮箱!

来自/Halliburton 译者/丁志莹 编辑/Leia

Fiber Optic monitoring services include a portfolio of distributed and point sensors used to evaluate wellbores from unconventional and mature field markets to heavy oil thermal and deep water environments. FiberWatchdistributed temperature and acoustic sensing provide evidence of fluid movement along the wellbore throughout the well life. FiberPoint™ sensing provides accurate pressure and temperature measurements within the wellbore to improve evaluation of fluid movement over time. Fiber optic conveyance is also critical to consider. SPECTRUMSM Diagnostic Service and FiberLog™ retrievable services as well as permanently deployed and pumped fiber applications each provide unique strengths with respect to fiber conveyance to fit the need for any downhole application.

FiberWatch DTS Hydrogen Tolerant (HT) System

The FiberWatch DTS hydrogen tolerant (HT) system is designed to provide DTS results in the harshest upstream environments. This system incorporates our patented dual-laser technology to mitigate effects of degradation to capture meaningful data on multi-mode fiber that may have previously been unusable. The interrogator is designed for long-term monitoring to assess life of well performance.

FiberWatch Distributed Temperature Sensing (DTS) Single Laser (SL) System

The FiberWatch DTS SL (single laser) system is a proven and tested design that has been deployed globally and proven to work in almost any environment. The single laser system has been adopted as a more cost efficient option for collecting reliable DTS results. This system also has a working range up to 15km.

FiberWatch DTS Single Mode (SM) System

The FiberWatch DTS SM (single mode) system is designed to provide reliable and confident DTS results specifically for single-mode fiber. This solution works in all markets from unconventional, mature fields, heavy oil, to offshore. This FiberWatch DTS SM system incorporates our patented dual-laser technology to mitigate effects of degradation and eliminate the need for double-ended measurements.

FiberWatch Distributed Acoustic Sensing (DAS)

Pinnacle, a Halliburton Service has successfully deployed fiber optics in over a thousand wells worldwide and provided valuable information to customers in various challenging environments. This includes covering markets from unconventional resources and mature fields to harsh thermal environments in heavy oil plays. FiberWatch Distributed Acoustic Sensing (DAS) is based on Rayleigh scattering principles used to determine acoustic strain signals over long distances, effectively turning the optic fiber cable into a series of virtual microphones. Once the data is acquired, advanced processing techniques such as frequency filtering, time and depth domain stacking, etc. can be applied to obtain information for a wide variety of applications.

Applications

StimWatch Injection Flow Profiling;

FlowWatch Production Flow Profiling;

Leak detection / Wellbore integrity monitoring;

Cross-well Analysis.

Features

Real-time data analysis;

Robust field ready unit;

FiberView visualization software.

Pinnacle DAS Advantage

Halliburton acquired Optiphase to further develop the acoustic sensing arm of our industry leading fiber-optic product line. This acquisition has enabled Pinnacle to work closely with manufacturing to enhance the hardware performance. To complement industry acquisition, Pinnacle has developed FiberView™ software suite for real-time optical visualization for both DTS (Distributed Temperature Sensing) and DAS interpretation. From manufacturing and operations to data acquisition and analysis, our teams are focused on delivering a complete product that provides real value.

StimWatch Injection Flow Profiling

Our industry leading DAS solution provides real-time monitoring of injection fluid, to assess fluid entry points and fluid distribution along the wellbore. Halliburton’s ControlFracSM service allows operators to assess diversion effectiveness, such as Halliburton’s AccessFrac service solution, and determine cluster efficiency in real-time. As with other applications, this service utilizes DAS and DTS as complementary tools to confidently define fracture fluid distribution. This approach applies to a broad range of strategies including plug and perf stimulations, packer/sleeve completions, waterflood, and acid injection.

FlowWatch Production Flow Profiling

DAS is used as a complementary tool to improve understanding of flow distribution along the entire length of a producing wellbore. It is commonly used in collaboration with DTS to interpret and define flow allocation throughout the life of the well. DAS is now a mature technology that provides true diagnostic value across several applications, production analysis included.

Leak Detection/Wellbore integrity monitoring

DAS has been successfully used to pinpoint leaks in casing and production tubing. This technology is providing real value at identifying leak locations and saving significant time and resources to locate leak locations from other means. It has been used to identify leaks due to casing failure, tubing failure, and completion tool failure.

未经允许,不得转载本站任何文章:

石油圈

石油圈