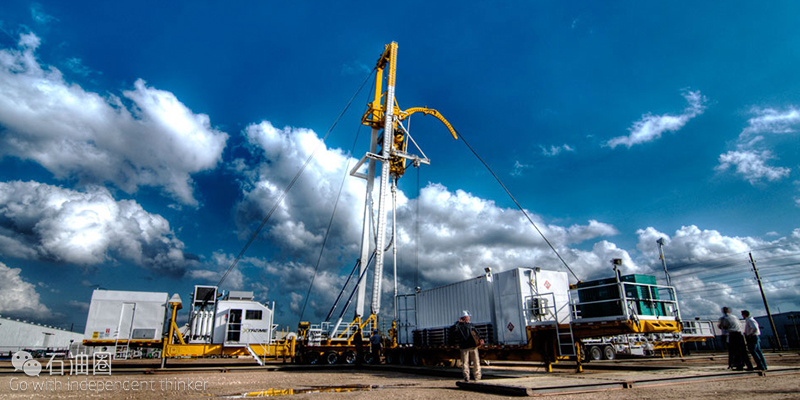

Halliburton’s Enhanced QuikRig next-generation coiled tubing system is designed with the well-control package preassembled on a mast, improving operational efficiency, reducing rig-up time, and creating a safer rigsite environment.

The system includes a new larger-capacity reel trailer, higher-capacity injector rated up to 125,000 lb, and an auxiliary mast unit with well-control equipment and power pack, with a new dedicated 60T/80T boom truck crane.

Applications

The Enhanced QuikRig System is suitable for most conventional coiled-tubing applications in both new and mature fields. However, due to its large-capacity well-control stack (up to 5 1/8-inch 15K)and its ability to contain a full milling bottom hole assembly (BHA)in its riser stack, the new Enhanced QuikRig System is especially suited for frac-plug mill-outs in unconventional plays.

The Enhanced QuikRig System is also versatile and can accommodate all standard V95 QuikRig unit reels and V95K injectors where lower pull capacities are required. The unique mast design enables a large variety of well-control equipment to be mounted on the trailer, ensuring a customized solution to nearly all your operational challenges.

Unique Three Unit Spread

Drawing on our highly specialized experience in all phases of well intervention and well control, our engineers have designed the new Enhanced QuikRig Unit system with three main components:

•Auxiliary Mast Unit – The mast unit consolidates all well-control and power systems for the package on a single trailer, reducing well site footprint and emissions

•Reel Trailer – the trailer comprises the reel, operator house, gooseneck, and injector in one unit

•Terex Truck Crane – the dedicated crane—by one of the industry leaders—provides all the lifting support for the coiled tubing well operation, delivering field-proven reliability to help ensure your operation runs smoothly

Features and Benefit

•Pre-assembled well-control stack significantly reduces rig-up time

•Mast trolley system reduces the possibility of dropped objects

•Latching mast design eliminates the need to make up the BHAs below a suspended crane load, increasing safety of well personnel

•Versatile reel trailer can handle all standard V95 QuikRig trailer reels

•Versatile reel trailer can accommodate both V95K and new 125K injectors on tilt trailer

•Can adapt to accommodate a variety of well-control package sizes with varying riser-stack lengths

•Real-time capability reel trailer fully supports the new CoilComm fiber-optic service

Auxiliary Mast Unit

Given our heritage of being the pioneers of coiled tubing and for combatting difficult-to-control blowouts, we recognize that an enhanced attention to safety can overcome some rigsite issues before they occur.

With that understanding, we have designed an auxiliary mast unit for the Enhanced QuikRig system with safety as a primary focus, not forgetting operational efficiency saves rig time and associated costs.

The auxiliary mast trailer base is a stabilized work platform comprising front and rear outriggers, and also carries the coiled tubing hydraulic power pack, 110 V AC generator, mast unit with pressure-control equipment stack, fuel tank, and hydraulic-hose packages.

The auxiliary mast unit incorporates the pre-assembled well-control stack and mast trolley system, significantly reducing rig-up time by as much as 50 percent, as well as reducing the potential for dropped objects during rig-up.

The mast is raised to the vertical position using a hydraulic cylinder. Once raised into position, the injector latches onto the stripper assembly via an auto latch connecter, and the trolley system can, using the crane, be raised and locked into one of six predetermined positions.

All unit controls are located on a local control panel away from the mast area, placing the operator in a safer position away from the well. The variable-geometry mast unit can accommodate a variety of well-control package sizes and stack riser lengths. The mast unit is designed to handle a total of 45,000 lb load, including the following:

•Coiled-tubing guide

•Coiled-tubing injector

•Dual (over/under) stripper package with remote-operated injector connector

•30 ft integral-flanged riser sections

•Riser crossover

•Quad blowout preventer

•Flow cross with 2 × integral outlets

•Dual Combi blowout preventer

The integral work platform on the trailer provides the operator with a safe method of accessing the stripper assembly for redress between jobs.

The trolley on the mast unit incorporates a 2,000-lb hydraulic-operated BHA hoist to reduce the requirement for manual handling of the BHAs.

Reel Trailer

The new quad-axle reel trailer carries the reel with tubing, the operator house, and the tubing guide. The reel trailer can accommodate the existing 95K injector heads and the new 125K injector heads, both prestabbed on an injector tilt cradle, improving operational efficiency. The trailer can be configured to operate with all standard V95 QuikRig reels, and easily accommodate pipe sizes between 1-1/2-in. and 2-7/8-in.

The larger coiled-tubing house incorporates a larger-capacity (75-gallon) accumulator system and a new blowout preventer (BOP) panel layout and control system fully compliant with APIRP16 ST (Coiled-Tubing Well-Control Equipment Systems).

The new control panel enables the coiled-tubing operator to define and label up to six individual BOP control functions. The panel also facilitates the operation of up to three remote-operated, Lo Torc control valves.

This high-flow design not only helps ensure a maximum closure time of 30 seconds, but also reduces the potential for accidentally shearing the coiled-tubing string by the inclusion of safety caps over critical well-control functions.

The Coiled-Tubing Acquisition and Control system includes the InSite for Well Intervention and the field-proven ACE overFlecs control systems.

Used together with the InSite Anywhere remote software package and integral wireless network, registered users can display key well parameters on most remote devices.

This new generation of coiled-tubing operator houses and reels were designed to be fully compatible with Halliburton’s new CoilComm service. The new control layout enables numerous high-resolution displays allowing multiple users to view a real-time display of vital coiled-tubing and downhole-tool parameters. The reel trailer also supports Pinnacle’s Digital Temperature Sensing (DTS) and Digital Acoustic Sensing (DAS) services.

Terex Truck Cranes purposely sized to suit the requirements

All Enhanced QuikRig Coiled Tubing Systems are supplied with their own dedicated Terex boom truck crane. Each crane was purposely sized to suit the requirements of various pressure-control equipment (PCE) stacks. The Terex T780 (80T) Boom Truck crane was selected to safely lift up to a 5 1/8-in. 15K well-control stack over a 25 f radius. The crane is mounted on a standard Terex chassis, and has an integral 5,000 lb counterweight.

The EPA-compliant 500 HP Cummins engine, Fuller manual transmission, hydraulic power-assisted steering, and air-ride suspension enable the crane to travel at highway speeds of up to 65 mph.

The operator cab is climate-controlled, with both a cooler and flameless heater to enhance safety and comfort. Load management is computer-controlled with a Greer load-weight indicator. Standard safety features include an anti two-block device, shielded muffler, and an emergency stop button in the cab. Additional lighting on the crane boom can assist in the rig-up process during night time operations.

The smaller-capacity Terex Crossover 6000 (60T) boom truck crane was selected to safely lift up to a 4 1/16-in. 15M control stack over a 25 f radius. The Crossover 6000 crane is mounted on a standard Kenworth T800 chassis, and has an integral 3,000 lb counterweight. The Crossover 6000 crane shares the same common control enclosure and features of the T780 crane.

石油圈

石油圈