What is Micro CT?

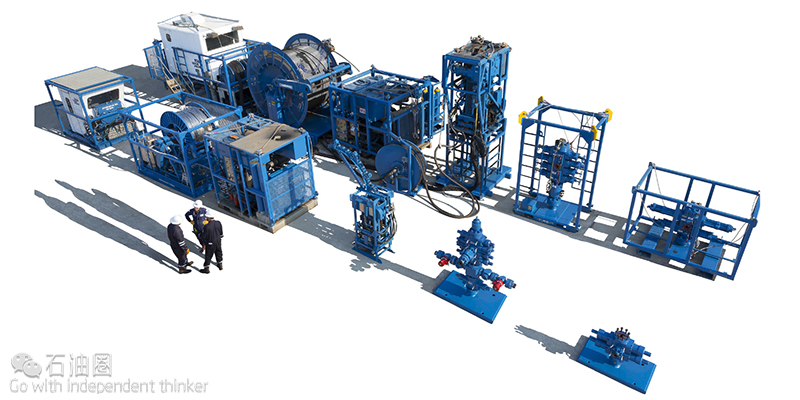

The Baker Hughes Micro CT Service leverages a modular, lightweight design and smaller footprint to provide an effective, efficient alternative to conventional coiled tubing (CT) units for offshore applications — especially on platforms where available deck space is at a premium or crane capacity is limited.

How it works.

The Micro CT service package incorporates specifically designed modular Baker Hughes CT equipment that meets DNV Lifting standards, Zone II specifications, Class 1 Division II specifications in Gulf of Mexico, and API Pressure Control standards.

Baker Hughes engineers have redesigned a standard CT unit into smaller and lighter modules. The unit breaks down into small components that are easily and quickly rigged up to reduce downtime and increase efficiency. The unit runs 5/8-in., 3/4-in., and 1-in. work strings with a 17,000-lbf pull injector head capacity. It can also be customized to run larger coiled tubing, injector heads, and reels if necessary.

Don’t compromise.

The Micro CT service provides a safe, more cost-effective solution to service even marginal wells, both offshore and onshore. It eliminates the need for self-erecting cranes and larger support/supply vessels costs. And the Micro CT components are easy to transport and rig up because of its lightweight, modular construction, thus also reducing logistics and support personnel requirements.

Add in industry-leading, proprietary CIRCA modeling software that will engineer confidence into your CT operation and well-trained, experienced Baker Hughes crews, the Micro CT service enables conventional CT work to be accomplished utilizing a smaller CT size and optimizing the operations while minimizing risk, with flawless execution.

Choose the Baker Hughes Micro CT service and get all of the efficiency of a traditional coiled tubing application without compromise… or unnecessary costs.

Micro CT Coiled Tubing Service

Reduce expenses by minimizing NPT and boosting workover efficiency

The Baker Hughes Micro CT service incorporates all the benefits and capabilities of a conventional offshore coiled tubing (CT) unit, in a compact, lightweight, small-footprint system. This new service permits offshore interventions on wells where it was previously economically unfeasible due to low production, the lack of available workover vessels, and/or deck-space/lifting-capacity limitations. The Micro CT service provides operators with a flexible, cost-effective intervention solution for offshore wells.

By eliminating the need for an onsite support vessel to deploy coiled tubing, the Micro CT service offers significantly more service opportunities for wells that are either shut in or awaiting service. This allows operators to transform idle assets into cash-flow contributors quickly and efficiently.

Applications

Offshore and onshore locations with lifting, space, or weight limitations, and restricted access

– Perforating, stimulation, cementing, and gas lifting

– Milling and cleanout operations

– Logging operations

– Mechanical intervention

Cleanouts

Stimulation treatments

Fluid lifts with nitrogen

Fishing operations

Scale removal

Hydrate removal

Asphaltene removal

Other remedial and intervention procedures

The Micro CT equipment can be deployed at any offshore wellsite without the additional logistical challenges typically experienced with CT operations supported by supply vessels and barges. The intervention and remediation work can be performed as often as required without the operator having to depend on the availability of expensive workover barges, rigs, or self-erecting cranes. This will save on both nonproductive time (NPT) and workover time, resulting in significant cost savings for the operator. Similarly, the Micro CT unit can be deployed in land locations where available roads might limit a conventional coiled tubing unit’s ability to gain access in a safe manner.

Proprietary Baker Hughes friction reducers significantly improve the pumping capabilities of smaller strings by minimizing the fluid friction in restrictions through the flow path down hole. As part of the inherent Baker Hughes pre-job analysis, proprietary CIRCA modeling software accurately predicts solid removal scenarios for cleanout purposes, and also provides a detailed mechanical stress analysis to visualize the string performance in the well.

Features and benefits

Lightweight, modular configuration

– Delivers a better, safer, and more versatile way to service marginal offshore wells

– Reduces logistics and onboard personnel

– Easy to transport and can be quickly rigged up

Minimal exposure to heavy lifts

– Increases efficiency, reduces footprint, and lowers risk

– Breaks down into small modular components

Meets all DNV lifting standards and Zone II specifications

– Offers full compliance for the most stringent of operations

Powerful Baker Hughes CIRCA modeling software

– Optimizes time on location by providing accurate job design, simulation, tool setup, and safe operating guidelines.

CIRCA Coiled Tubing Simulation Software

Optimize job designs, and save time for safe, efficient operations Using data specific to your application, the Baker Hughes CIRCA proprietary coiled-tubing modeling software accurately simulates coiled tubing operations. The advanced computational capabilities of the CIRCA software help ensure your job is completed in the safest, most efficient manner possible.

Refined during more than three decades of development, CIRCA software provides the industry’s most accurate predictions of tubing forces, pressures, fluid behaviors, wellbore solids removal, and downhole tool operations. Every CIRCA-designed job is supported by an unsurpassed knowledge base of industry experience. The user interface is made up of detailed, context-related help files, along with and a warning and messaging system based on actual physical conditions and lessons learned. It provides immediate guidance to the end user and serves as a real-time design aid.

The CIRCA coiled tubing software can effectively plan jobs for all proprietary Baker Hughes bottomhole tools and services, and helps make any coiled-tubing operation successful.

Applications

All standard coiled tubing operations

Baker Hughes proprietary applications

– Tornado coiled tubing cleanout system

– OptiFrac multizone fracturing services

– EasyReach extended-reach tool

– Roto-Pulse gravel-pack cleaning process

– Roto-Jet jetting tool

– Sand-Vac well cleanout system

– FoamExpert modeling software

– StimTunnel acid placement service

– EasyCut sand jet perforator

– Micro CT service

Features and benefits

Accurate job design and simulation based on actual operations

– Optimizes time on location and amount of material pumped

– Provides safe operating guidelines, situational advice, and warnings based on lessons learned

Models tubing forces and flow analysis

– Produces accurate calculation of maximum depth and force

– Predicts pressures for two-phase flow, gels, acids, and other slurries

– Provides a fluids database

– Maps theologies with temperature and pressure measurements

石油圈

石油圈