In many cases, carbonate oil wells are stimulated by acidizing methods which can be inaccurate, inefficient, and otherwise complicated. The results of acid flushes and acid fracturing can vary widely making interpretation and repeatability difficult. A new stimulation solution has been developed to be simple, efficient, and accurate in using acid to create laterals into the formation, making contact with existing natural fractures and bypassing formation damage.

Fishbones’ Multilateral Stimulation Technology defines a new level of precision and efficiency in reservoir stimulation. You can vertically connect the reservoir throughout a long well in one short pumping operation.

The Fishbones system is installed as a part of a liner string into drilled reservoir section. Fishbones subs are spaced out to target specific parts of the reservoir and each sub contains four small diameter tubes with length up to 40 feet. A typical acidizing fluid system is utilized and when pumped fluid jets of out nozzles at the end of each tube. The formation ahead of the tubes is jetted away with a combination of erosion and acid chemical reaction. Differential pressure across the liner drives the tubes into the formation penetrating the rock until fully extended. All laterals are created simultaneously in a short pumping job, resulting in a fishbone style well completion with multiple laterals extending from the mainbore. The liner with the extended tubes becomes a permanent completion with included production valves, which allow flow to enter the liner.

Products

Fishbones MST-Jetting

Small diameter hollow needles with jet nozzles are installed with and protected by the liner.

At depth the needles are released by pressuring up the liner. The fluid jets out of the nozzles, and the formation ahead of the tubes is jetted away by a combination of erosion and acid chemical dissolution. Differential pressure across the liner drives the needles into the formation, and they penetrate the rock until fully extended. 4 laterals are installed at each depth.

Penetration length of the Fishbones laterals is the makeup length of the liner. Typically 12 meter (40ft) is achievable penetration, creating real and significant stimulation effects. Do you need 50,100 or 200 laterals? You are in control.

Fishbones MST can be used with acid for jetting of carbonates or non-reactive fluids for other formations (Carbanates, Coal bed methane, Oil sands).

Dreamliner MST-drilling

Small diameter hollow needles with drill bits and turbines are installed with and protected by the liner.

At depth the needles are released by circulation of drilling fluid with the rig pumps at specified rates. Each needle is driven by a turbine powered by the fluid circulation. Three laterals are drilled from each Dreamliner sub and the laterals’ length can be up to 35.4ft / 10.8m. All laterals are drilled simultaneously. The laterals drilling operation is completed in few hours.

Dreamliner MST can be used in most formation types including sandstones.

Backbone openhole anchor

Fishbones has developed the next generation open hole anchor. It can be used in a variety of formations including carbonate, shale and sandstone.

Its unique and simple design allows for unprecedented load capacities in overgauge hole. The anchor can be used in combination with the Fishbones and Dreamliner MST systems or in any other well where pressure and temperature changes may cause movement of the string.

Fishbones and Dreamliner activation shoes

The Fishbones acid releasable float shoe allows circulation while running in hole. It closes upon contact with acid, allowing pressure activated equipment to operate.

The Dreamliner activation shoe is available in open and closed configurations and is activated prior to the laterals drilling.

Fishbasket

Fishbasket is a junk basket specifically designed to clear the liner ID after permanent Fishbones stimulation installation.

It cuts and collects needles, enabling wellbore access.

Applacations

Fishbones’ Multilateral Stimulation Technologies are field proven in sandstone, carbonate and coal bed methane formations. MST improves reservoir stimulation delivering the accuracy of cemented and perforated, the operational efficiency of open hole slotted liners and the productivity of fracturing. Our solution will depend on your formation.

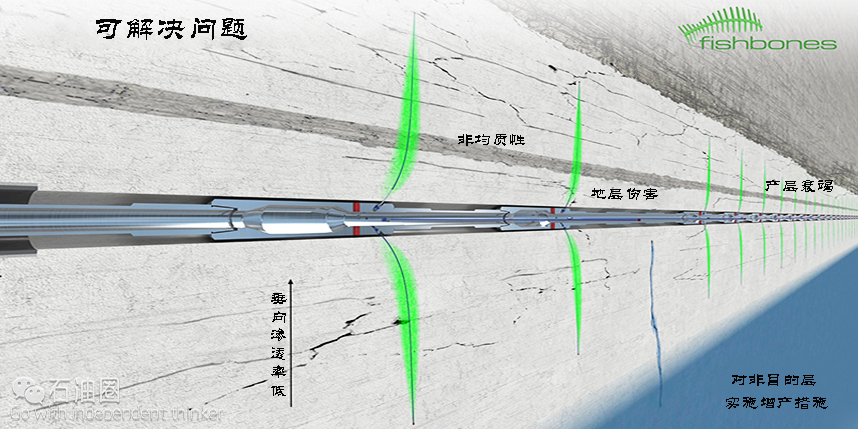

MST can be used in a range of applications. The list below is not exhaustive, but gives an overview of typical applications were MST can make a difference:

Increase productivity in producers

Increase injectivity in injectors

Increase reservoir contact in low permeability reservoirs

Connect layered reservoirs, bypass vertical permeability barriers

Connect naturally fractured reservoirs

Accurately stimulate zones without the risk for penetrating into unwanted zones e.g. in thin reservoirs

Connect with sweet spots and lenses missed during geosteering

Stimulate wells with varying pressure regimes

Reduce drawdown and reduce coning effects in long horizontals

MST is feasible in new and existing horizontal, deviated and vertical open hole wells.

Connect your reservoir with simplicity, accuracy and efficiency. To evaluate your application we need to know more about your well. The more information we get, the better advice we can give. Please ask us for the Well Information Sheet.

Case Histories

Fishbones MST installation #2 in USA

JCR installation #2, June 2015

Buda formation, Texas

Tight, fractured limestone

Horizontal well, 6 1/8” open hole

15 ea. Fishbones subs, 3 ea. Backbones

Successful installation

60 laterals, 4 hrs total pumping time

Similar pump chart profile as first well

First Dreamliner MST installation

Offshore Norway, July 2015

New well in tight sandstone formation

2012m / 6600ft horizontal section

8.5” open hole with 5.5” liner

48 ea. Dreamliner subs – 144 laterals

7 ea. Backbone open hole anchors

Successful installation

Liner run to TD without issues

6 hours mud circulation time for laterals drilling

Pressure responses indicate extension of needles

First offshore Fishbones MST installation

Fishbones Multilateral Stimulation Technology (MST) was successfully installed in a new sidetrack in an offshore well in the Middle East early January 2016.

The objective of the installation is to increase productivityfrom a tight, layered carbonate formation.

The 4.5in. lower completion, comprised of 20 each Fishbones MST subs and three each Backbone open hole anchors spaced out with liner joints and hung off with a liner hanger, was deployed troublefree in the 6in. open hole from a jackup rig. The pumping operation was performed from

vessels.

石油圈

石油圈