由于井下工具失效或者井内杂质太多等原因,油气井经常无法实现最大产能。大多数井内流体的透明度过低,油公司一直无法对井下实际情况进行准确成像。

Visuray公司设计VR90的最初目的是实现精确成像,并准确诊断出井下安全阀的状态,以便让作业者对后续的修井作业进行更好的设计。石油圈原创www.oilsns.com

VR90使用独特、紧凑的X射线源不断发射出X射线,直接探测工具以下的容积。这些反向散射的辐射数据将通过开创性的地面重塑技术转化成2D和3D图像。相比于其他传统手段,通过使用X射线,VR90工具在任何井下生产流体中都能适用,不被能见度所制约。石油圈原创www.oilsns.com

井下能见度的提高能让油公司得以更好地设计修井作业,从而精确高效地解决这些问题。同时,VR90 X射线成像工具能获得多个井下测量数据,并为客户提供有价值的信息。

这些性能表明,不论是在井下环境还是在海上作业中,VR90都能够获得非常精确的井下X射线成像。

VR90是一种电缆工具,包含的热离子X射线管具有必备成像系统组件。按照设计,工具和程序的作业温度范围为室温到150°C(300°F),承受压力达到1380bar(20000 psi)。工具的最大外径为9.2 cm(3 5/8 in),最大长度为8.38m (27.5 ft)。该工具可以同各式各样的电缆以居中或者偏心的方式下入井内,还可以同爬行器、往复推送器和连续油管实现兼容。

实验室环境下的成像试样表明,在清水、盐水、石油和含有悬浮铁锈微粒等各类不同的常规生产流体中,VR90均具备重塑物体形态的能力。另外,这些试样说明,该工具具有高度的准确性,成像精度达到毫米级别。石油圈原创www.oilsns.com

总之,VR90是一种多功能工具。即使是对于非常具有挑战性的井,VR90也能提供有用的信息,同时还可节约时间、降低成本、提高安全,并最小化环境风险。

打捞井下工具通常需要通过打捞筒和打捞矛勾住芯轴来实现。如果这两种方式都无法捞获落鱼,那作业者面临的挑战将是非常巨大的。也可以选择下入铅印,但一般来讲,这种方法是不可靠的。另外,作业者可以采取直接磨掉的方式,但这这种方法非常耗时,而且成本高昂,破坏性极大。

然而,作业者可以下入VR90 X射线诊断工具来确认打捞尝试失败的原因。

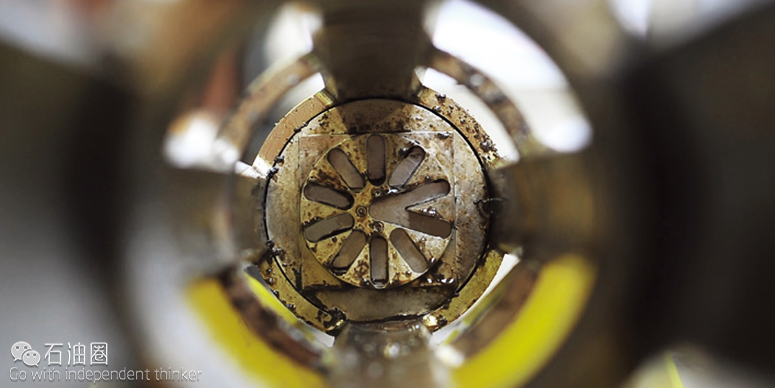

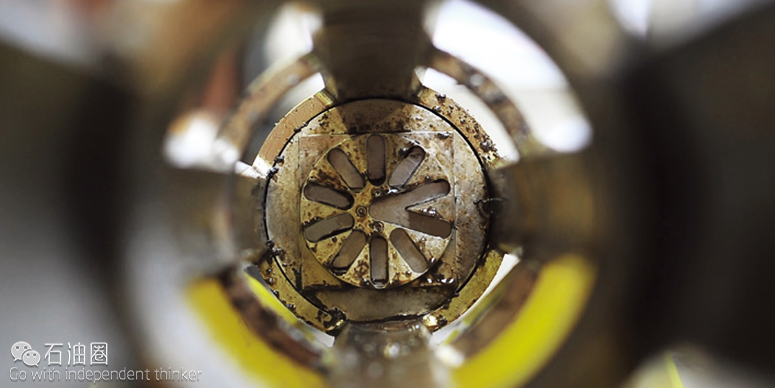

在某次现场作业中,Visuray公司的试验装置上获得的其中一个成像显示,中芯轴已经被压坏,因此打捞矛无法从内部勾住芯轴,外部的打捞筒也无法卡住芯轴。VR90不仅对井下情况形成了清晰成像,还帮助作业者设计了一个特制的打捞工具,在不损坏落鱼的前提下迅速将硬件打捞上来。

技术应用

- 检查井下设备,如井下安全阀和芯轴;

- 对井眼内限流情况进行分类和量化;

- 判断井下落物的外形和规格;石油圈原创www.oilsns.com

- 识别并刻画变形套管、破裂套管;

- 为设计特制的打捞工具提供信息。

技术特点

- 适用于所有生产流体环境,能对被砂掩埋的物体进行成像——避免替液、洗井或者对井液进行化学性循环,节约时间和资金;

- 作业温度高达212°F/100°C,作业压力高达20,000psi / 1,380bar——能在之前无法涉足的井眼环境下进行作业;

- 采用本质安全的电子X射线源——简化后勤管理;石油圈原创www.oilsns.com

- 提供及时的在线反馈信息——在世界任何各地都能综合各种信息作出最正确的决定;

- 可以用居中或者偏心的方式下入井内——操作弹性更强;

- 可以结合各式各样的电缆下入井内,还可以同爬行器和往复推送器兼容。

Visuray公司为客户提供VR90工具的商业服务,可帮助油公司深入井内,洞悉井内情况,同时探索出一条致力于提高油气井完整性的路线。

“X射线工具已在海上油井中取得了成功应用,整个作业过程安全且流畅。在满足客户要求的同时,我们也证明了VR90的可靠性,”欧洲的销售总监Sergey Feoktistov说到,“随着VR90 X射线技术不断获得大众的好评和认可,我们期望在世界范围内推广相关业务,帮助客户优化修井作业,并节约作业成本。”

关于Visuray公司石油圈原创www.oilsns.com

Visuray公司是一家为客户提供X射线成像技术服务的油服公司,旨在减小客户的修井等作业风险。公司拥有近50个物理学博士和来自20个国家的工程师,在斯塔万格和休斯敦等地均有办事处。

小编手中还握有VR90 X射线成像技术的更多资料哦,想获取?很简单:请将此文章分享至朋友圈,发送截图和邮箱地址至石油圈微信后台。小编会将资料打包奉上,发送至您的邮箱!还有机会与技术专家沟通交流哦~

来自/Visuray 译者/郑斯赫 编辑/Leia

Oil and gas wells often fail to produce to their true potential thanks to malfunctioning downhole hardware or debris in the well. Because of the opacity of most well fluids, oil companies have had no reliable means of imaging a well’s physical condition. Visuray’s VR90 tool uses ground-breaking X-ray technology to provide precise downhole images irrespective of well fluid. The improved visibility allows oil companies to plan well interventions that address these issues precisely and efficiently.

The objective was to image and unambiguously diagnose the status of a downhole safety valve so the operator could plan future workover operations. Visuray’s VR90 X-ray imaging tool acquired multiple downhole measurements and provided valuable information for the client. The results demonstrate the VR90’s unique ability to obtain dimensionally accurate downhole X-ray images in opaque well fluid environments and in offshore operations.

VR90 is a wireline tool that incorporates the thermoionic X-ray tube with the necessary imaging system components. Both the tool and its operating procedures are designed to operate at ambient temperatures of up to 150°C (300°F) and withstand pressures up to 1380 bar (20000 psi). The tool has a maximum outer diameter of 9.2 cm (3 5/8 in) and a length of 8.38 m (27.5 ft). The tool can be run on all types of electric wireline and either centred or eccentred in the well, and is compatible with tractors, strokers, and coiled tubing.

Example images from operating the tool in a laboratory setting demonstrate the ability of the tool and technique to create reconstructions of objects in a variety of normal production fluids including clean water, saline water, oil, and fluids with suspended rust particles. The images also demonstrate the millimetre-scale resolution and accuracy of the tool. Altogether, this represents a versatile tool with the capabilities to provide useful information in challenging well management scenarios and do so while saving time, reducing cost, improving safety, and minimising environmental risk.

‘To our knowledge, this was the first time an X-ray tool has ever been run in an offshore well. The job went safely and smoothly, and in fulfilling the customer requirement we’ve proven the reliability of the VR90 tool and service,’ says Sergey Feoktistov, Sales Director Europe. ‘As Visuray’s downhole X-ray diagnostic service gains credibility and visibility, we look forward to expanding our operations worldwide and enabling our customers to optimize well interventions and save operating costs.’

Retrieving downhole hardware is often achieved by engaging a mandrel with overshot or spear. If both techniques fail to retrieve a fish, the operator is left with quite a challenge. An impression block can be run, but this generally proves unreliable. The operator can proceed directly to milling, but this is time-consuming, costly and destructive.

Instead, the operator can run the VR90 X-ray diagnostic service to determine the cause of the failed fishing attempts.

The image (right) obtained at Visuray’s test facilities shows a case where the mandrel has been crushed, and hence the spear tool would not fit inside nor the overshot around the mandrel. Additionally, the VR90’s dimensionally-accurate images allow the operator to design a custom fishing tool and quickly retrieve the hardware without destroying it.

A unique and compact X-ray source emits X-rays that probe the volume immediately below the tool. Measurements of the backscattered radiation are then converted into 2D and 3D images using an innovative fluid-based surface reconstruction technique. By using X-rays rather than other conventional methods, the VR90 tool works in any downhole production fluid, however opaque.

APPLICATIONS

- Inspection of downhole equipment such as valves and mandrels;

- Classification and quantification of wellbore restrictions;

- Determination of shapes and dimensions of dropped objects;

- Identification and characterization of collapsed or split casing;

- Providing input for design of customized fishing tools.

BENEFITS

The VR90 is now available to provide services. It is a downward-viewing imaging tool that:

- Works in all production fluids, and can image sand-covered objects -– saving time and money by eliminating the need to displace well fluid, clean up or chemically

- condition the well;

- Operates at temperatures up to 212°F/100°C* and pressures up to 20,000psi / 1,380bar – providing answers in previously inaccessible environments;

- Uses inherently safe, electronic X-ray sources – simplifying logistics;

- Produces real time answers online – enabling well-informed decisions anywhere in the world;

- Works centered or eccentered in the well – for extra operational flexibility;

- Runs on all types of electric wireline and is compatible with tractors and strokers.

made or selected and the fish is retrieved.

Today, the Visuray team has grown to more than 50 professionals from about 20 countries, offering the VR90 commercial service to allow oil companies to see inside their wells, while charting a path forward to improve oil and gas well integrity, and eliminate radioactive materials from the oilfi eld.

未经允许,不得转载本站任何文章:

石油圈

石油圈