Tracerco provides rapid pig location and effective pig tracking systems ensure that time is saved in locating any lost or stuck pigs. This enables operators to apply the necessary procedures to allow the pipeline to return to normal operating conditions in the shortest time possible.

Explorer for Flow Assurance

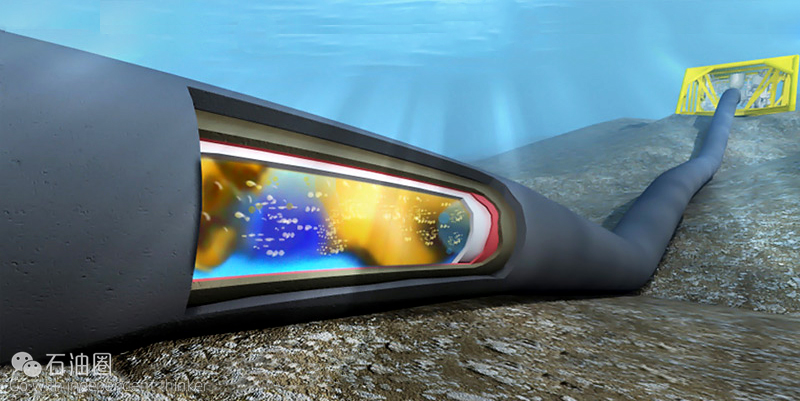

Tracerco has developed Explorer for Flow Assurance to provide pipeline operators with a reliable screening service to determine the location of deposition build-up for further investigation.

Explorer for Flow Assurance unique technology allows many kilometres of subsea pipeline to be quickly scanned, enabling the location of deposits causing flow abnormalities to be easily identified. With a typical screening speed of up to 100 metres per hour, several kilometres of line can be surveyed per shift, providing operators with a simple and convenient solution to detecting and locating content and deposit build up.

Lee Robins, Head of Subsea Services at Tracerco, said: “Accurately detecting the location of blockages caused by a build-up of deposits is an on-going issue for the oil industry. Having listened to the needs of our customers, we are delighted to be able to launch Explorer™ – a speedy and innovative low-risk solution.

“Tracerco is now able to provide subsea operators with a fast screening means of locating their pipeline deposits and blockages, Explorer – followed by precision characterisation using Discovery.”

As with Discovery, Explorer is non-intrusive, scanning content from outside of the pipeline. There is no need to remove protective coatings or interrupt production to carry out the inspection, making it a cost-effective solution to flow assurance problems.

Explorer can operate at depths of up to 3,000m (10,000ft) and can cover pipe diameters from 2 to 60 inches. It has the ability to screen a variety of different piping systems: standard rigid pipe (coated or uncoated), pipe-in-pipe, bundle systems and flexibles.

Explorer detects the location of deposit build-ups by measuring the density profile of the pipeline and then analysing any detected anomalies. An abnormal density, in relation to the material flowing in the line, indicates a build-up of deposit. The tool provides a detailed profile showing mean densities of pipeline contents and amounts of deposit based on assumed densities. It has already been used on several subsea flowlines including a project in the North Sea, as well as a campaign in the Gulf of Mexico. So far Explorer™ has delivered excellent results for the customers who have used it, proving effective in deposit detection as well as being straight forward to deploy.

Benefits of Explorer for Flow Assurance:

Non-intrusively detect the location of deposition build up quickly without interrupting production

Real-time data on flow profiles

Monitor changes in deposition for an enhanced understanding of remediation efforts.

Track the flow regime at specific reference points along the pipeline

Quickly identify flow assurance issues that may need further investigation

Quickly and non-intrusively locate any lost or stuck pigs

Explorer for Flow Assurance has been developed in conjunction with Discovery, the world’s first pipeline inspection tool that provides a full CT scan and a detailed tomographic image of subsea pipeline contents. Discovery is utilised to further investigate flow abnormalities to characterise deposition build-up such as hydrate, wax, asphaltene or scale once Explorer has determined the location of the suspected blockage area. Both technologies non-intrusively scan the line, eliminating the need to remove the coating or interrupt production, creating a cost effective solution to flow assurance issues. Explorer and Discovery combine to enhance understanding when diagnosing flow assurance problems, allowing operators to effectively plan for remedial action.

Case study

EXPLORERT ALLOWS NORTH SEA OPERATOR TO PIG SUBSEA PIPELINE WITH CONFIDENCE

Explorer, the latest product from world leading technology company Tracerco, part of the FTSE 100 Johnson Matthey Plc, has completed a successful analysis of pipelines in the North Sea.

The operator was preparing to undertake a pipeline pigging cleaning campaign of two 8-inch production flowlines feeding an offshore platform, and was concerned that any deposition would result in the cleaning PIGs becoming stuck and causing an obstruction, which could potentially result in revenue losses running into millions of pounds in deferred production. Prior to the cleaning campaign commencing, Tracerco was asked to use Explorer technology to locate and quantify any deposits along the length of both pipelines. This would allow the operator to understand the cleanliness of the line prior to the cleaning campaign. They could then commence the project with confidence, or plan any further investigations and modify the cleaning methodology depending on the results obtained from Explorer.

Explorer works by scanning pipelines through any type of coating to obtain a density profile of its content. By comparing the known material flowing, Explorer is able to identify any variances which indicate a build-up of deposit. This allows customers to screen pipelines very quickly to determine the location of any deposits. Once this has been determined they can decide on the best course of action, or in this case the potential risk of a stuck pig.

The customer was provided with a detailed profile of the two flowlines in question, showing the results for each of the positions analysed. The operator was satisfied that the small amounts of deposition found in the line would not be enough to obstruct the cleaning PIGs and was able to commence the cleaning campaign with certainty that any depositions would not cause a bigger and more costly issue.

“Previously, inspecting a pipeline from the outside was costly and high risk. The advantage Explorer brings is that as well as removing the risk and cost of removing coatings, it also scans pipelines online therefore ensuring no deferment of production for the customer; a huge business benefit of using this technology. The customer was really pleased with the data that they received and the expertise of the Tracerco team who handled the deployment and provided immediate onsite analysis and reporting of the results.”

石油圈

石油圈