现代油田需要更简单、更安全、更稳定的井下技术。自膨胀封隔器水平井完井技术式以遇油/遇水自膨胀封隔器作为主要环空风格工具对水平井进行完井的。由于该完井工艺简单,能够缩短玩井时间,降低完井风险和费用,已成为油田水平井开发中的一项关键技术。

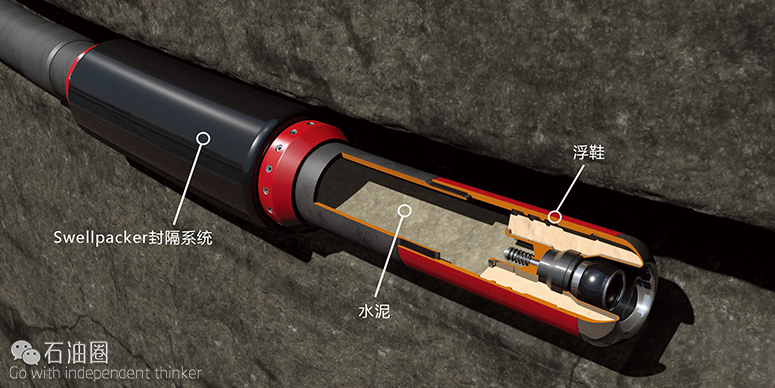

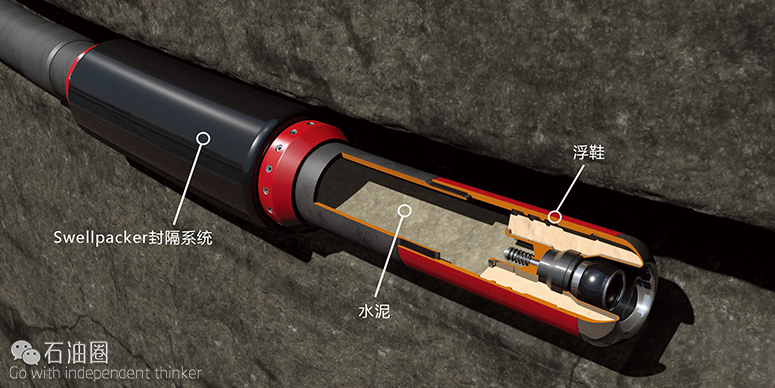

哈里伯顿Swellpacker系列自问世以来,在中东、北海油田已经成功应用上千次。该技术基于特殊橡胶遇水/油膨胀的特性,体积可膨胀至原体积的2倍,从而密封环空周围,实现有效的层位隔离。部署就位后,该封隔系统可依然保持其膨胀灵活性,适应地层压力随时间的变化,进而保持封隔的完整性。石油圈原创www.oilsns.com

同油管结合后,Swellpacker能够根据基管长度任意调整封隔段长度。另外,Swellpacker具有极高的强度和强大的承压能力。

Swellpacker封隔系统在套管或裸眼环境中均可使用。在裸眼作业中,运营商可通过使用该封隔系统减少其他相关作业成本,节省钻进时间并封隔生产层位,这也将油田产能推到了一个前所未有的高度。石油圈原创www.oilsns.com

除上述功能,Swellpacker封隔系统还可用于初次注水泥作业,进一步保证井筒完整性。该系统可提供长期的全面层位隔离,在延长油气井寿命的同时,还可减少昂贵的潜在修井费用。

延迟膨胀系统

为了确保井筒中的水或油在封隔器下入过程中不会对封隔器造成影响,哈里伯顿设计了多种系统实现推迟膨胀进程,作业者可以根据需求控制膨胀进程,调整坐封时间,减少提前坐封的风险。该系统包括缓膨聚合物以及多种扩散隔膜,独立或组合使用均可,同时也可根据用户的井况对系统进行自定义设计。

防挤出挡环设计

除了开发高弹性塑料复合物外,哈里伯顿在膨胀封隔器系统设计中的各个领域都进行着深入研究,如防挤出挡环的设计。防挤出挡环不但能增加封隔器承受的压差,而且能够在工具入井时起到引导膨胀的作用。根据应用条件和冶金要求的不同,该设计可以通过定位螺钉、造褶或者焊接来实现锚定。

K2防挤出挡环能够在封隔器入井时保护橡胶元件,并且在封隔器坐封后防止橡胶被挤出。这种独特挡环可以在保证承受压差能力的同时缩短工具长度,可将工具承受的绝对压差提高到15000psi。

电缆系统

Swellpacker系统能够通过一个独特电缆联通线下入单根或多根控制管线、井下监控管线、化学品注入管线等,且SmartWell完井系统也不用对管线进行切割。如此,整个作业过程无需电缆铰接、控制管线切割和剥电缆等作业,极大降低了使用电缆的潜在风险。Swellpacker系统不但为套管井和裸眼井提供了环空密封,还赋予了控制管线和数据传输管线较强的承压能力。电缆穿过SwellPacker系统的过程与完井作业同步,全程无需额外的钻进时间。

系统安装

安装Swellpacker系统前需要进行简单的检查,然后随完井管柱或尾管关注下入井中。与此同时即可进行生产,开始膨胀进程,或者将当前流体引入封隔器以引起膨胀,也可直接循环专用膨胀液。Swellpacker系统的安装无需专门的安装人员,哈里伯顿提供的工具使得控制管线和扁平管壳在转盘上的安装变得毫无压力。

技术特点

- 可以在任意油田管柱上加工;

- 适用于套管井和裸眼井;

- 结构坚固;石油圈原创www.oilsns.com

- 无移动部件;

- 具有自我修复能力,减少修井次数;

- 可在所有流体环境中使用;石油圈原创www.oilsns.com

- 多种聚合物材料可提供遇油膨胀、遇水膨胀、混合膨胀等特性;

- 膨胀延迟系统。

技术优势

- 安装时不需要现场专家;

- 维护套管完整性;

- 完美适配不规则井眼形状;

- 减少作业风险;石油圈原创www.oilsns.com

- 更有效地封隔生产层位;

- 帮助减少油井成本和钻进时间。

应用范围

- 裸眼井和套管井;

- 裸眼井和套管井跨隔;

- 监控、化学品注入;

- 出水率控制;

- 独立筛网防砂;石油圈原创www.oilsns.com

- 划分筛网/ICD 完井;

- 砾石充填封隔;

- 建井。

应用案例

Swellpacker系列产品目前已在全球多个区块实现了成功应用。

越南的一个客户首次决定在一口高温高压井的16寸尾管中下入13-5/8”套管并固井。哈里伯顿推测,由于在16”尾管和13-5/8”套管之间存在偏差,这口井将面临严重的漏失问题。此次工程的主要目的是提供一个能够继续钻进的管鞋;从而为新增的层位隔离提供一个二级屏障,防止其被高循环当量密度和管鞋下的低压区域所影响。

哈里伯顿提出使用Swellpacker封隔系统来帮助提高井筒完整性。由于钻井作业仍在继续,作业者要求在6周内工具必须到达井场。而且更具挑战的是,客户提出,在入井前对系统进行初步实验,以证明SwellPacker系统能够满足作业者的要求。石油圈原创www.oilsns.com

13-5/8”的Swellpacker系统准时送到,实验也证明该系统能够满足这次作业要求。顺利部署入井后,封隔器成功封隔,效果超出了作业者的预期。固井结束10天,Swellpacker工具入井14天后,环空压力为0且没有升高。同时,带有延迟封隔系统的Swellpacker封隔器系统也为初次固井提供了高可靠性的次级封隔。

自膨胀封隔体系在当前油田中有着广泛的应用。该技术在油田的推广应用大幅度降低了完井费用,同时也减小了完井事故,提高油井产量,具有重大的现实意义。

小编手中还握有Swellpacker和Halliburton其他产品的更多资料哦,想获取?很简单:请将此文章分享至朋友圈,发送截图和邮箱地址至石油圈微信后台。小编会将资料打包奉上,发送至您的邮箱!还有机会与技术专家沟通交流哦~

来自/Halliburton 译者/曾旭洋 编辑/Leia

Today’s oilfield requires operators to find simpler, safer, and more stable downhole technologies. The Halliburton Easywell Swellpacker isolation system is an innovation that meets all of these criteria. The technology is based on the swelling properties of rubber in hydrocarbons or water, or in both. It swells up to 200%, sealing the annulus around the pipe to achieve effective zonal isolation. Once deployed, the rubber retains its flexibility, allowing the Swellpacker isolation system to adapt to shifts in the formation over time, retaining the integrity of the seal. Its self-healing properties make this a truly innovative technology for all zonal isolation applications. It is a bonded to pipe product that can be delivered with any element length depending on the basepipe length. Since the rubber is bonded to the basepipe, it is extremely robust and can hold significant differential pressures.

The Swellpacker system can be used in cased or openhole environments. In some openhole applications, operators may be able to avoid cementing and perforating altogether, reducing the expense associated with these operations. By reducing well construction costs, saving rig time, and isolating producing zones, the Swellpacker system helps enable previously unachievable levels of oilfield performance.

Cementing Support

For well integrity issues, the Swellpacker isolation system can also be used to complement the primary cement job.The system provides comprehensive long-term zonal isolation, increasing the productive life of the well and minimizing the potential of an expensive workover operation. This combination of proven technologies provides an effective means to address both micro annulus concerns and incomplete cement sheath issues.

Swelling Delay Systems

To ensure that the oil or water contained within the well fluid does not affect the packer while it is run into the hole, Halliburton has engineered several systems that can delay the swelling process. These enable control of the elastomer swelling process as the setting time can be tailored according to the customer’s needs, mitigating the risk of premature setting while optimizing the operating envelope.The systems include polymers with built-in slower swelling properties and a variety of applied diffusion barriers. Customizing a design with either of these options, or using in combination, allows for creation of a well-specific engineered product.

End Ring Design

In addition to the elastomer compound development, Halliburton continues to innovate in all areas of the Swellpacker isolation system design, including the end rings.These important components assist in increasing the differential pressure capability and guide the packer when run into the hole. Depending on the application and metallurgy requirements, the design can be anchored using set screws, a crimping process or welding. In addition, Halliburton has developed a new type of end ring. The K2 end ring protects the rubber element while running in hole and further eliminates element extrusion once the packer is set. One of the benefits of this unique end ring is the ability to shorten the tool length, while maintaining differential pressure. It also increases absolute differential pressure performance of the tools with testing done up to 15,000 psi across the packer.

Swellpacker Cable System

The Swellpacker system can be delivered with a unique cable feed-through option which enables the passage of single or multiple control lines and flat packs for downhole monitoring, chemical injection and SmartWell completion systems without the need to cut the cables or lines. This removes the requirement for cable splices, control line cuts and cable stripping, greatly reducing the risk of failure. It provides an annular seal in cased and open hole, and a seal around the control lines or flat packs capable of holding differential pressure. Installation of the cables through the Swellpacker system is performed on the rig floor at the time of running the completion and requires no extra rig time.

Installation

To install the systems, simply perform standard pre-job checks, then run in hole as part of the reservoir completion string or liner system. At that point either produce the well to begin the swelling process or allow the current well fluid to swell the packer systems prior to operations or circulate down the designed swelling fluid. The simplicity of the operation means that specialized installation personnel are not required. For the cable design, Halliburton provides the installation tool that fits easily on the rotary table and installs the control cable or flatpack through the packer.

Features

- Manufactured on any oilfield tubular;

- Suitable for cased and open holes;

- Robust construction;

- No moving parts;

- Spliceless cable feed-through option;

- Self-healing, interventionless technology;

- Can be run in most all fluid environments;

- Multiple polymers available to provide oil-swelling (OS);

- water-swelling (WS) and hybrid-swelling (HS) solutions;

- Engineered swelling delay system.

Benefits

- No specialist operator required for installation;

- Casing integrity is maintained;

- Ideal for irregular borehole geometry;

- Alternative solution to cementing and perforating in;

- certain applications;

- Complements cement to resolve well integrity issues;

- Helps reduce operational risk;

- Isolates producing zones more effectively;

- Helps reduce well costs and rig time;

- Cable feature increases system reliability by eliminating cable;

- splicing and enables openhole SmartWell completion systems.

Applications

- Open and cased hole isolations;

- Stimulation placement;

- Open and cased hole straddles;

- SmartWell completion systems;

- Monitoring and chemical injection;

- Water control;

- Multilaterals;

- Stand-alone screen sand control;

- Compartmentalization for screen/ICD completions;

- Gravel pack isolation;

- Well construction.

Application

OVERVIEW

A major operator in Vietnam decided to run and cement a 13 5/8-in casing inside 16-in. liner for the first time in its high pressure/ high temperature (HP/HT) field. Halliburton determined severe fluid losses could be expected due to the very tight annular tolerance between the 13 5/8-in. casing and 16-in. liner. The primary objective was to provide a good shoe to drill ahead and a secondary barrier for added zonal isolation should the cement column be impacted by the high equivalent circulating density (ECD) and the low pressure zone below the casing shoe.

Halliburton proposed using its Swellpacker isolation systems to help ensure well integrity. Since drilling operations were ongoing, the operator needed to have the equipment delivered to the wellsite in only six weeks. Adding to the challenge, a lab test was required to prove that the Swellpacker system design would meet operator internal approval before running it in the well.

The 13 5/8-in. Swellpacker system was delivered on time, and the required lab test report confirming that the packer could be safely run was provided several days before the operation was to begin. The Swellpacker system was then deployed and sealed successfully, exceeding operator expectations.

CHALLENGE

Reliable secondary barrier zonal isolation in the event of severe losses during the cement job to avoid expensive remedial operations.

- Severe fluid losses anticipated;

- Well control due to huge volume of mud losses to formation and annulus pressure buildup;

- Packer OD of less than 14.65-in. after four days;

- Logistical obstacles to delivering the solution on time.

SOLUTION

Swellpacker systems with delay fusion layer to provide highly reliable secondary barrier to primary cement for zonal isolation.

RESULT

Swellpacker systems provided effective zonal isolation control along with good shoe to drill ahead provided by cement, saving the operator money and optimizing logistics.

- 13 5/8-in. Swellpacker system was installed trouble-free;

- 10 days after the cement job and 14 days after the Swellpacker system passed the rotary table, the pressure in the C-annulus was at zero and no more pressure had built up.

未经允许,不得转载本站任何文章:

石油圈

石油圈