Halliburton’s Completion Tools business line, a long-standing industry leader in total composite plug technology, today introduced the Illusion® frac plug, the only fully dissolvable frac plug on the market. The new high-performance, 10,000 psi rated product shortens the time to production by eliminating the need to mill out plugs after fracturing, saving time and money for operators.

The Illusion frac plug revolutionizes plug-and-perf completions for fracturing in unconventional markets. Plugs can be installed at any position in the wellbore to enable optimal placement of perforations for improved fracturing, without prepositioned locator subs or other equipment that remains in the wellbore post-frac. Illusion frac plugs dissolve completely to leave an unrestricted bore for production, and since no intervention is required to clean the wellbore after the frac, risk is reduced and production may be brought on sooner to improve the net present value (NPV) of the asset.

Artie Burke, vice president of Completion Tools said, “We have successfully run Illusion plugs for our customers in the Eagle Ford, Bakken, and Woodford shale plays. This is a truly game-changing technology for the industry. We’re excited to bring this next-generation product to the market that will reduce risk, allow production to commence sooner and improve the overall cash flow for our customers.”

The Illusion® dissolvable frac plug is the latest addition to the Halliburton Unconventional Completions portfolio. This high-performance frac plug is rated to 10,000 psi for zonal isolation during wellbore stimulation and combines Halliburton’s industry-leading frac plug designs with the most advanced dissolvable metal and rubber materials. The large bore ID allows operators to produce through the plug while it remains in the wellbore and begins the dissolution process immediately following fracturing.

The Illusion frac plug not only helps alleviate the cost and time of plug mill-out operations, but it also helps remove the risk associated with coiled tubing. Fewer operational steps are required to get a well onto production, reducing rig time as well as personnel and equipment on the rig site, and decreasing the potential for safety and wellbore issues. Since no intervention is required to clean the wellbore after the frac, production may be brought on sooner to improve the net present value (NPV) of the asset.

The Illusion frac plug is a compact design that aids in pump down efficiencies as well as allow faster run-in-hole line speeds while setting the tools on wireline. Higher pump rates and increased wireline feed rates allow the operator to deploy Illusion plugs on depth faster and more efficiently.

Illusion dissolvable frac plugs also provide a solution for extended reach horizontal wellbores where tubing weight can be an issue for milling out conventional frac plugs. Since these plugs dissolve away, they can be set in the toe of the wellbore without the need for coiled tubing removal.

Illusion frac plugs are based on Halliburton’s current line of composite plugs, thus no field operation changes or special instructions are needed to successfully run and set these plugs. A simple adapter kit connects the Illusion frac plug to the most commonly used setting tools run today.

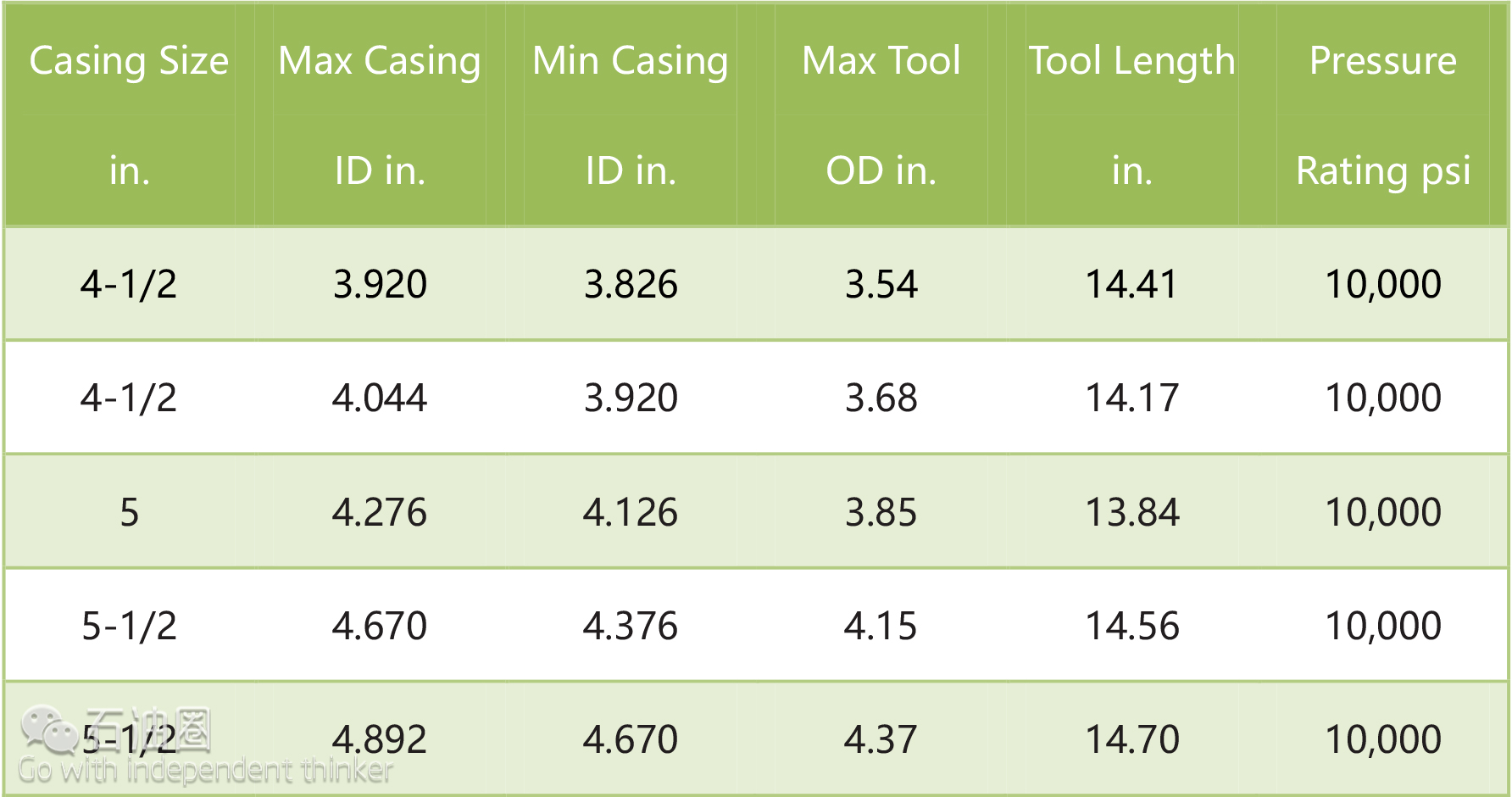

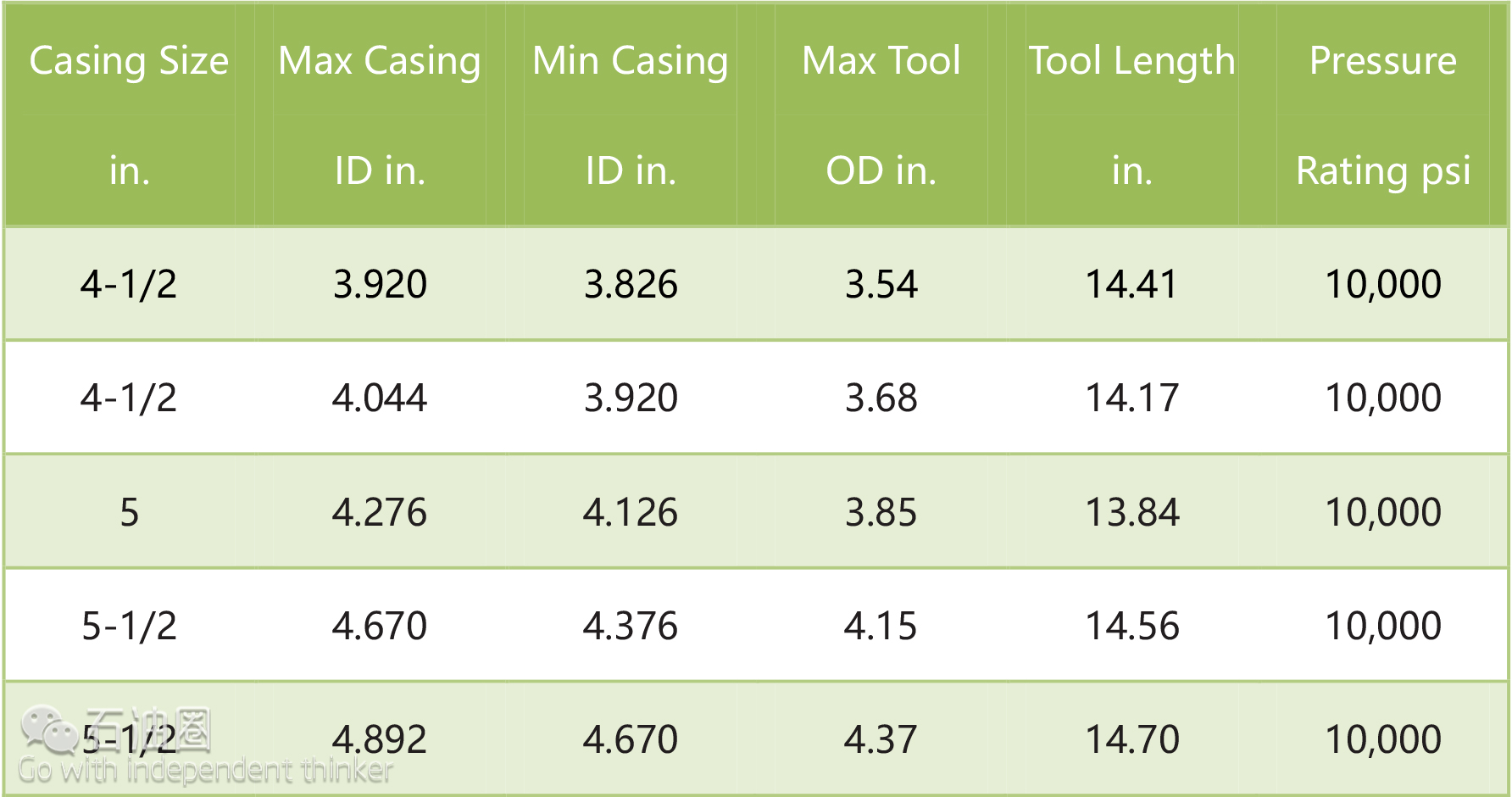

Illusion Frac Plug Specifications

Illusion plugs are currently available in 4 1/2-in. and 5 1/2-in. casing sizes, with a differential pressure rating of 10,000 psi.

- Made from materials that dissolve over time based on temperature and salinity;

- Large ID to assist immediate flow back and well cleanup;

- Designed for accelerated pump down rates;

- High-performance metal plug for demanding frac stimulations.

Illusion®Frac Plug Helps Eliminate High-Risk Millout Operations

OVERVIEW

A major operator drilling in the Bakken and Three Forks formations in the Williston Basin was concerned about depleted reservoir conditions due to close well spacing. The operator needed a solution that would eliminate the wellbore intervention step required to clean out traditional composite frac plugs. The wellbores consisted of 4 1/2-in. production liners averaging 10,000 feet total vertical depths with 10,000-foot horizontal sections. On a previous well, the customer experienced a costly incident where the millout string and bottomhole assembly got stuck due to the depleted reservoir conditions, requiring an extensive fishing job.

Halliburton recommended dissolvable Illusion®frac plugs for the plug-and-perforate operation to resolve the customer’s intervention concern. Upon successful completion of the 35+ stages, which required no special wireline installation equipment or pump-down procedures, the plugs dissolved, intervention was eliminated and flowback efforts were uninterrupted. The well was put onto production, achieving initial flowback, and sustained months of production that matched expectations.

CHALLENGE

For upcoming high-density well-spacing trials, the operator primarily wanted to remove the risk of intervening in the depleted wellbore when milling out composite plugs. Those risks, unmitigated, can put higher-density drilling programs at risk due to the steep costs and time delays created when millout challenges are encountered.

SOLUTION

Halliburton recommended Illusion frac plugs as an alternative to the traditional composite frac plugs being provided by another service company. Illusion frac plugs are fully dissolvable and help eliminate the need for intervention prior to putting the well onto production.

This high-performance frac plug provides zonal isolation for pump-down applications during wellbore stimulation, and combines Halliburton’s industry-leading frac plug designs with the most advanced dissolvable metal and rubber materials. The large-bore ID allows operators to produce through the plug while it remains in the wellbore and begins the dissolution process immediately following fracturing.

RESULT

The Illusion dissolvable frac plugs were pumped down and set without issue during the fracturing operations. Run-in-hole speeds exceeding 400 feet per minute through the horizontal were achieved — a conservative, but typical application of Illusion plug efficiency and reliability.

The customer was able to successfully flow back the wellbore and start production without issue or the need for a wellbore cleanout intervention. This alone saved a minimum of $250,000 in costs typically attributed to a millout operation and, more importantly for this application, helped eliminate the risk and cost associated with their previous millout experience.

Because Halliburton Illusion frac plugs completely eliminated the need for intervention, the application was a success for the customer. Days were saved bringing the well onto production, boosting the overall economic performance of these well projects.

Illusion®Frac Plugs Help Eliminate Post-Fracturing Treatment Intervention

OVERVIEW

An operator in the Williston Basin wanted to reduce or eliminate the cost and time associated with post-fracturing treatment millout operations. Two wells, similar in construction with a ~10,000-foot vertical section and a ~10,000-foot lateral, were completed using Halliburton fully dissolvable Illusion® frac plugs.

In over 49 stages, there were zero issues in running the plugs to depth, setting, and withstanding fracturing treating pressures. After the fracturing treatment was completed, the two wells were flowed back for three days. Both wells met operator expectations during initial flowback operations, allowing the operator to place both wells onto production without completing a coiled tubing millout.

CHALLENGES

In an ongoing effort to reduce the cost of completing a well using the plug-and-perforate method, an operator in the North Dakota Williston Basin was looking to reduce or completely remove the time and investment required to complete a post-fracturing treatment millout, an operation which has become standard practice with composite fracturing plugs.

SOLUTION

Despite dissolvable technology being relatively new, the Illusion frac plug has had over 1,000 successful installations in the Williston Basin alone. Halliburton knew that this fully dissolvable plug could reliably stand up to the challenges of this operation, while helping meet the operator’s goal of eliminating post-frac millout. This plug features a large inside diameter that allows for fluid to flow through the plug during flowback or production, and a fully dissolving rubber element and metallic body. It is run-in-hole just as a composite frac plug would be, making installation quick and easy.

RESULT

A total of 49 Illusion frac plugs were pumped and set at the desired depths with an average line speed of 570 ft/min through the vertical section and 450 ft/min in the lateral section of the wellbore. The plugs required minimal fluid volumes to pump down, minimizing the risk of formation damage and reducing completion costs. All 49 plugs held up to fracturing treating pressures, even after hours of down time and wellbore fluid exposure.

Upon completion of the fracturing treatment, the wells flowed back successfully. The operator then rigged up the production equipment and allowed both wells to continue to produce. A post-fracturing treatment millout was never needed, saving the operator an estimated $200,000 in completion costs on these two wells. Eliminating the millout process wiped out operator concerns, giving them peace of mind as well as extra dollars back in their pocket.

石油圈

石油圈