Investors of Aberdeen-based well intervention specialist READ Cased Hole welcome continued growth of their portfolio company as it takes its latest logging technology, ZeroTime to launch at the SPE ICoTA Coiled Tubing and Well Intervention Conference & Exhibition in Houston.

Despite difficult market conditions for majority of the oil and gas sector operating in the North Sea, READ has seen several contract wins over the last months, thanks to its established reputation as a market leader in efficient and cost optimized production and integrity evaluation.

Determined to stay agile in the current market and with a commitment to delivering fast, accurate answers to its customers, READ is launching ZeroTime in an era when the industry is in need of innovation to achieve a step change in efficiency and cost optimization like never before.

ZeroTime

ZeroTime provides a smart way to log while working, giving customers fast, accurate answers that help maximize efficiency.

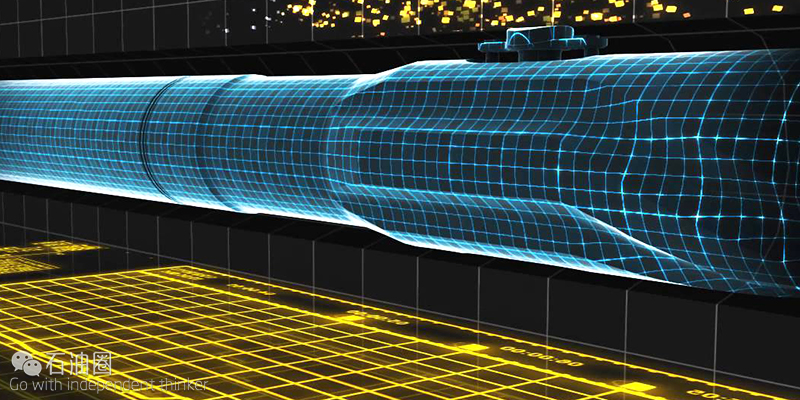

ZeroTime is a multi-functional memory logging system, comprising a suite of ruggedised sensors, that allows the operator to record fluid temperature, pressure, gamma ray and CCL response in conjunction with mechanical intervention operations. Our specially designed drill pipe and coiled tubing carrier systems ensure maximum data integrity without compromise to function and capability, allowing you to operate as normal, but with added diagnostic intelligence.

Whether deployed on slickline, coiled tubing or drill pipe ZeroTime technology integrates straight into the bottom hole assembly using standard connections, maintaining tension, compression, torque and pump-through characteristics. The assembly requires no special treatment and can be kept at the wellsite for the duration of campaign activities, with READ’s specialist engineers mobilizing on demand, as and when required, for each well in the sequence.

Through close collaboration with a select number of multinational operators and global oil and gas companies, ZeroTime has been tried and tested under the rigours of the North Sea, establishing an outstanding track record for operational efficiency along the way. As a logging while working solution ZeroTime facilitates precision diagnostic data to be acquired during high-force mechanical interventions. By integrating into almost any bottom hole assembly, ZeroTime eliminates the need for standalone logging runs, simplifying well interventions and delivering critical decision-enabling answers in a significantly reduced time frame. READ’s ZeroTime client case studies demonstrate how the elimination of dedicated well surveys results in saving of circa 24 hours, and associated operating costs, per well intervention, as well as significantly reducing the risk of safety incidents.

With over 800 successful surveys to date it is a game changing solution based on straightforward technology. The combination of smart technology and specialist knowhow significantly reduce operating time without compromise to operational performance or with regards to the accuracy of the acquired data. ZeroTime services comprises of the use of a novel, ruggedized, memory logging system deployed in specifically designed high-strength carrier assemblies for use in slickline, coiled tubing and drill pipe conveyed well interventions. READ’s specially trained engineers perform on-site analysis using bespoke software applications to deliver detailed and to-the-minute downhole intelligence which operators can use to assess the effectiveness of interventions enabling rapid, decisive decision making to enhance their next move.

石油圈

石油圈