The Weatherford OmniWell solution offers a complete range of production and reservoir monitoring solutions from simple, single-gauge installations to complex, multizone, intelligent wells.

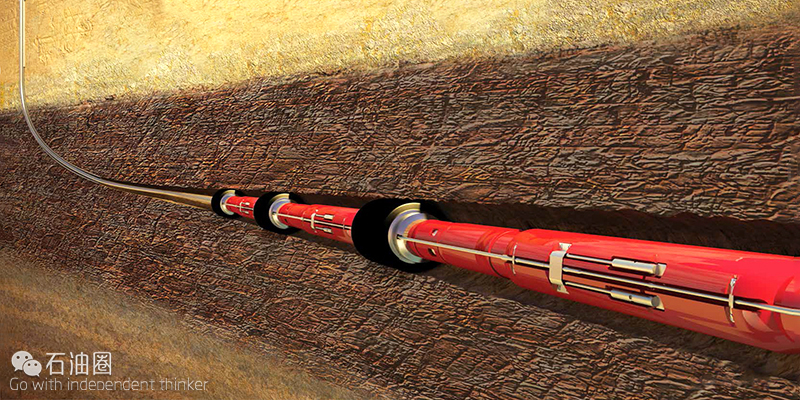

The OmniWell solution is a unified family of pressure, thermal, flow, acoustic, and seismic products. These innovative tools give you an accurate view into your well by providing data acquisition, information management, and analysis for any type of well. Based on a single-cable approach to downhole measurement, our system physically integrates multiple measurement sources and visualizes well-performance data in real time, which provides information that helps accelerate production, reduce operational risk, and maximize reservoir recovery.

OmniWell includes electronic silicon-on-insulator (SOI) gauges, optical sensors, and quartz gauges as well as pressure, thermal, flow, and seismic solutions. With several options to fit any production environment, we ensure that you get the right solution for your wells.

No longer a new, unproven technology, optical sensors have evolved into the premier life-of-well monitoring solution for hostile subsea wellbores. Our quartz sensors represent the next generation of hybrid electronic technology. With fewer electronic components placed downhole, our quartz system mitigates opportunities for failure and helps to extend the life of the equipment.

Advantages

Reduced Operating Costs and Risks

1.Eliminate interventions

2.Decrease the amount of persons required on board

3.Avoid deferred production costs

Optimized Production

1.Improve well design

2.Enhance stimulation, artificial lift, and sand control

3.Monitor formation damage

4.Analyze pressure losses

5.Manage sand-face pressure drop

6.Minimize shut-in time for pressure buildup surveys

7.Help determine the cause of unplanned shutdowns

8.Accelerate production and realize revenues sooner

Improved Reservoir Management

1.Expand your understanding of a reservoir and its characteristics

2.Acquire real-time data based on actual performance, rather than relying on predicted performance

3.Establish unchanging reference points and eliminate repeatability errors from reusing temporary sensors

4.Quantify contributions from independent reservoir zones and commingled wells

5.Monitor independent reservoirs in multilateral wells

6.Monitor reservoir drainage and bypassed hydrocarbons

7.Capture seismic imaging

8.Predict future production and recovery for various development strategies

Consistent and reliable downhole data informs better reservoir decisions and increases recovery, well life expectancy, and profitability. But in subsea environments, environmental conditions that cause vibrations and extreme pressure and temperatures challenge reliable data. The risk for equipment damage or failure is high—which prevents you from getting the information you need while causing delays and costly, complex repairs. Permanent monitoring systems remove the need for intervention, which reduces costs and operational, production, safety, and environmental risks. Through our OmniWell product portfolio, Weatherford offers a range of permanent downhole sensors and data acquisition units suited for diverse subsea applications.

Subsea Applications

High Temperatures and Pressures

With only the most durable components installed downhole and critical instrumentation kept at the surface or on the seabed, OmniWell tools can operate in the most demanding environments with exceptional accuracy and resolution. Optical sensors can monitor in-well pressures and temperatures in conditions up to 572°F (300°C) and 30,000 psi (268 MPa), and quartz sensors are rated for conditions up to 392°F (200°C)and 25,000 psi (172 MPa).

Pressure/Temperature Applications

P/T gauges define production efficiency. When used with flow-control valves or inflow control devices, these gauges help to enable uniform production and to eliminate wireline intervention resulting in production downtime.

Well Startup Monitoring

P/T sensors measure real-time reservoir pressure and manage initial drawdown. Our supporting software, including the PanSystem and PanMesh programs, creates interference tests and conducts pressure transient analysis to provide reservoir boundary information.

Downhole Flow Measurement

Real-time flow measurement is critical for optimizing production in complex subsea wells, including multizone and multilateral completions. This data can reduce or eliminate the need for surface well testing and the associated operational, safety, and environmental risks. Configured to measure single-phase and multiphase flow rate, our optical in-well flow meters are bidirectional, scalable to any pipe size, and do not restrict the flow path. Our optical flow meters can be used with our Red Eye subsea water-cut meter for sensitive water-onset detection and tracking water production throughout the life of the well.

Artificial Lift

Quartz gauges monitor P/T data to help analyze and automate all forms of artificial lift. With permanent monitoring, you can help to reduce production downtime or losses while extending the operational life of artificial-lift equipment.

Zonal Isolation Monitoring and Pressure Transient Analysis

Our quartz gauges help you monitor your ever-changing well dynamics. With their high resolution, these sensors can detect even the slightest variations in pressure and temperature.

Distributed Temperature Sensing

Distributed temperature sensing (DTS) creates a thermal profile of the entire well by logging a time-lapse record of temperature changes—typically per meter—across a production zone. This data can be used to monitor the performance of water, steam, and gas injections; to optimize gas-lift operations; and to identify flow anomalies, including tubing or casing leaks, flow obstructions, and thief zones.

Array/Multipoint Temperature Sensing

We space multiple optical array/multipoint temperature sensing (ATS) devices throughout an area of interest in the wellbore to provide reliable, accurate, and stable temperature data that is used to measure subtle production-induced thermal changes. ATS devices, which achieve real-time measurements up to 100 times the resolution and 25 times the accuracy of DTS, can also provide reference points for DTS measurements.

Production and Injection Profiling

Optical DTS and ATS systems help to establish production and injection profiles across the reservoir sections of horizontal, multilateral, and multizone wells.

Sand Control

Placed inside or outside sand screens, optical systems are adept at gathering data across perforated intervals and openhole sections.

Multizone Completions

In multilateral completions and wells with commingled production from stacked reservoirs, optical flow meter data can help resolve issues with production allocation. This data can also help to determine the productivity index for individual zones or the entire well.

Case study

Location:Rivers State, Nigeria

Well Type:Onshore swamp oil producer

Products/Services

1.OmniWell CanePT optical permanent downhole gauge system

2.OmniWell nFORM wellhead reservoir monitoring system

Objectives

Provide a permanent downhole pressure/temperature (P/T) gauge (PDHG) system to gather accurate, reliable real-time reservoir data and pass the data to a wireless radio that is capable of data transfer from a remote location.

Value to Client

1.The successful installation of the Weatherford optical downhole gauge system and a wellhead data acquisition unit provided the client access to real-time reservoir data as required.

2.The optical sensing system, which requires no downhole electronics, provides the client highly reliable technology for the life of the well.

3. The client eliminated the cost of mobilizing personnel for manual reservoir data retrieval, which for this particular well historically exceeded US$100,000 annually.

石油圈

石油圈