Combining high-quality monopole and quadrupole measurements, the SonicScope multipole sonic-while-drilling service s real-time compressional and shear slowness—along with Stoneley data—in any formation, rdeliveregardless of mud slowness.

These measurements enable more confident decisions while drilling, helping you eliminate unnecessary casing strings, mitigate risk and improve safety, reduce nonproductive time, and save drilling days and costs.

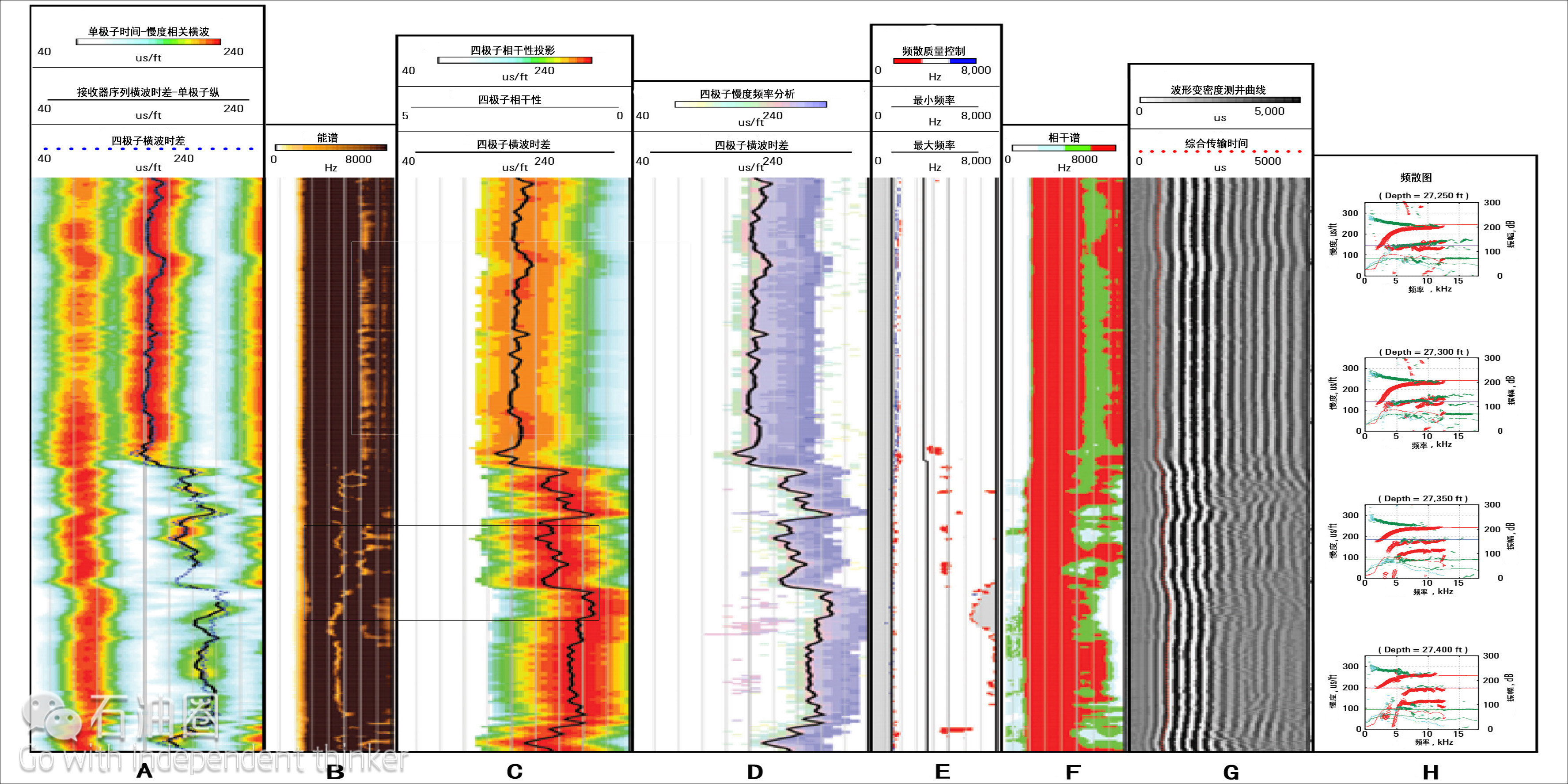

The SonicScope service offers a variety of logs and plots that enables a thorough quality-control process for data confidence.

Real-time wellbore stability

By allowing real-time mud-weight window management, the SonicScope service helps you manage wellbore stability while avoiding kicks and losses, reducing stuck pipe risk, and minimizing nonproductive time.

This evaluation, independent of formation temperature and salinity effects, helps you properly evaluate the pore pressure and fracture gradient so that the mud-weight window can be adjusted to mitigate drilling risks.

Real-time sonic-to-seismic tie

The SonicScope service’s robust real-time compressional data can be used to build a synthetic seismogram that reduces well position uncertainty. Placing the bit on the surface seismic map enables you to make critical geosteering, landing, and geostopping decisions while drilling.

Real-time petrophysical evaluation

Robust compressional and shear measurements can help identify gas presence and estimate porosity without using radioactive sources that require complex logistics and added risk.

This makes the SonicScope service particularly advantageous in carbonate reservoirs because it only responds to interconnected porosity.

Real-time well integrity

Real-time cement evaluation enables detecting cement placement even before the shoe is drilled out.

This evaluation gives firsthand insight into the integrity of the cement job and facilitates safer, more informed decisions.

Completions optimization

A unique firing mode enables Stoneley wave acquisition while drilling, before any washout can develop.

The Stoneley wave is sensitive to open, permeable fractures intersecting the wellbore along with formation fluid mobility and formation shear slowness.

Integrating Stoneley measurements allows an accurate interpretation of reservoir quality, geology, fracture network, and rock mechanics, helping you optimize completions to maximize production potential.

The SonicScope service computes real-time and recorded compressional and shear (P&S) data in both fast and slow formations.

Comprehensive data quality control

To reduce uncertainties with data, the SonicScope service offers a variety of logs and plots as part of a thorough quality-control process, enabling operators to evaluate data from the acquisition of waveforms to the computed compressional and shear data.

A.Slowness time coherence: provides full visualization of coherent arrivals and associated slowness.

B.Quadrupole spectrum: details the frequency content of the waveforms; the darker the spectrum, the stronger the energy.

C.Quadrupole coherence projection: represents the accuracy of the shear inversion.

D.Quadrupole slowness frequency analysis: determines the energy of the propagating waves by projecting the dispersions onto the slowness axis at each depth.

E.Dispersion QC: identifies how well the model from quadrupole inversion results fits the data.

F.Semblance spectrum: highlights the frequency bandwidth over which the quadruple data is coherent.

G.Waveforms variable density log: enables QC of the waveform from a specific reservoir for compressional arrival and also checks if borehole washouts affect waveform amplitude.

H.Dispersion plot aids in understanding the different acoustic modes propagating in the borehole and is key for quality control of the processed slowness answers.

SonicScope service dispersion plot

Dispersion plots help you understand the different acoustic modes propagating in the borehole and are key for quality control of the processed slowness measurements. They allow validating that the proper mode has been selected in the case of monopole, quadrupole, or Stoneley as well as that the processing has been correctly applied.

Slowness dispersion plot in slow formations

•Compressional answer is identified in the higher-frequency range of the monopole source data as a nondispersive compressional head wave.

•Quadrupole shear answer is extracted from the low-frequency part of borehole quadrupole mode using model-based inversion.

Slowness dispersion plot in fast formations

•Compressional answer is identified in the higher-frequency range of the monopole source data as a nondispersive compressional head wave.

•Shear answer can be extracted from both monopole source data as a shear head wave, quadrupole source data, or both.

•Quadrupole shear answer is extracted from the low-frequency part of borehole quadrupole mode using model-based inversion.

Case Studies

SonicScope Service Real-Time Data Enables Correct Bit Positioning and Improved Well Placement

Enhance drillbit positioning

An operator sought to correlate real-time sonic-to-seismic data from continuous sonic compressional data and to accurately position the bit for coring-point selection and geostopping. Schlumberger recommended the SonicScope service in combination with the ImPulse integrated MWD platform and adnVISION service, an integration that would provide high-quality quad-combo data while drilling. Both compressional and shear data were provided continuously and reliably in real time using the latest downhole labeling algorithm.

Data were made available in real time through the InterACT global connectivity, collaboration, and information service, enabling effective remote decision making and data quality control. A geophysics data expert was linked in real time, allowing batch creation of a synthetic seismogram and correlation with surface seismic data via an internal plug-in to the Petrel platform. Continuous compressional and compressed density via the Orion II high-speed telemetry platform were provided in real time with 6-in sampling while drilling at 100ft/h, enabling a synthetic seismogram to be created with recorded-mode accuracy.

Correlation of this information with surface seismic data allows better positioning of the drillbit, even defining the location ahead of the drillbit and enabling proper management of drilling hazards and casing points. The well trajectory can also be refined during drilling while reducing uncertainties from the original predrill information.

Interpretation ahead of the bit

Integrating geophysics in the real-time workflow helps drilling operations by better positioning the drillbit. Surface seismic information is used to define targets, well path, pore pressure trends, associated casing depth, and the presence of faults and drilling hazards. However, surface seismic information is not depth constrained. This information is acquired in time and then converted to depth using modeled velocities that often contain large uncertainties, especially in exploration operations or areas with poor surface seismic resolution.

Optimal well positioning

The addition of real-time, continuous compressional data from sonic and density measurements provides critical information for seismic tie-in, updating information along the wellbore and providing correlation for interpretation ahead of the bit and for future offset wells. Previously, recorded-mode data were used because real-time data were often not continuous, and data quality was sometimes insufficient for these advanced techniques.

The use of real-time, high-quality data enabled the operator to better position its wells and safely drill the planned sections. The data were also used for pore pressure prediction and wellbore stability.

石油圈

石油圈