The NEW Sentry® ISOLOK® API (anvil piston instrument) automatic sampler suite provides four distinct solutions to optimize sampling accuracy and repeatability for hydrocarbon liquids, including crude oil, condensates, and oil and water mixtures. Don’t settle for the status quo. All API samplers offer superior performance and a long life, minimizing maintenance, accessories and service time needed.

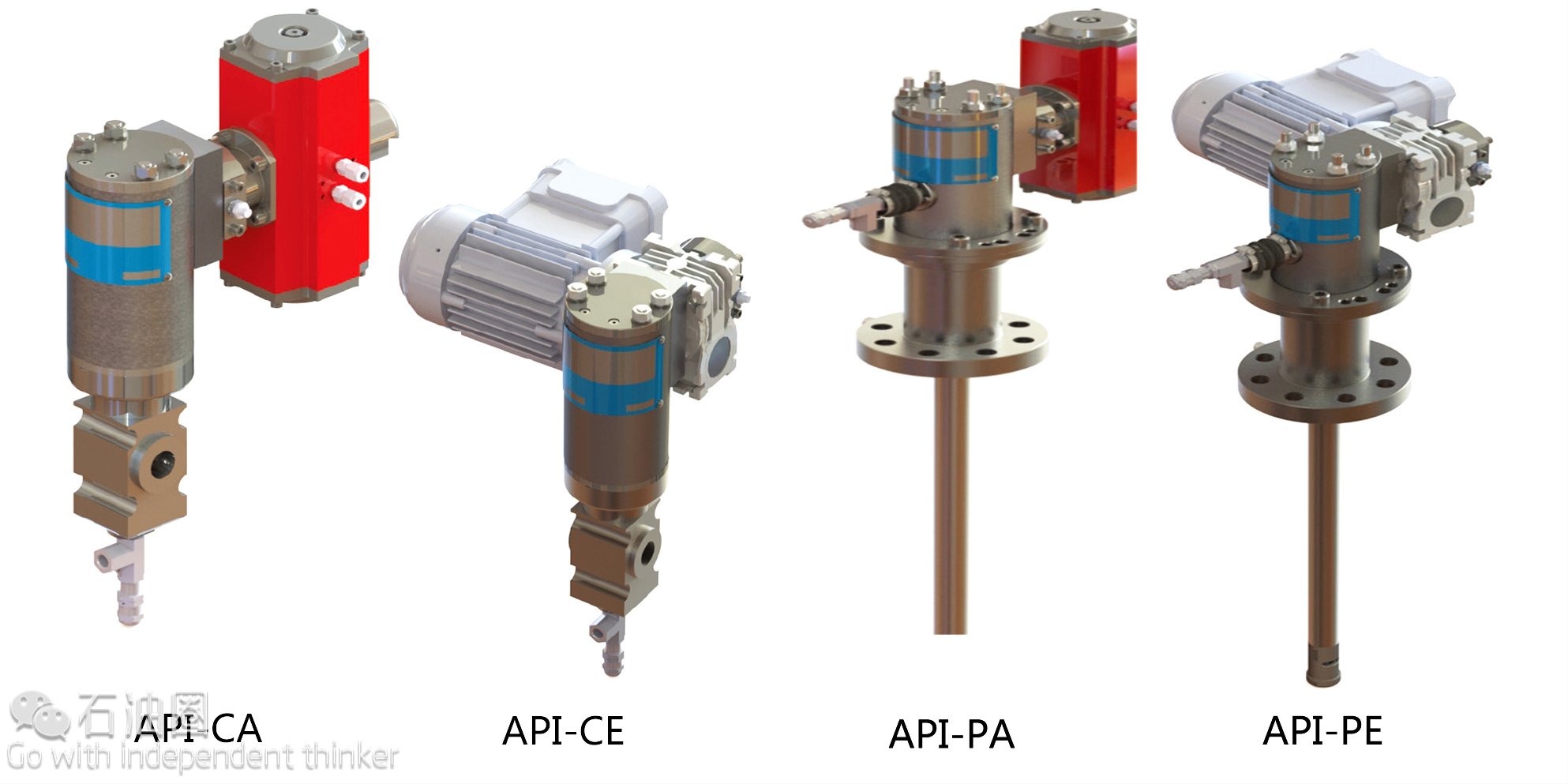

Meet the:

Sentry ISOLOK API-CA – Cell sampler used with bypass or fast loop sampling systems employs a 180-degree pneumatic actuator and is ideal for energized mixing and blending applications.

Sentry ISOLOK API-CE – Cell sampler used with bypass or fast loop sampling systems employs an electric actuator for applications in which pneumatics are not available, and is ideal for energized mixing and blending applications.

Sentry ISOLOK API-PA – Probe sampler used in-line employs a 180-degree pneumatic actuator and is ideal for installing where product is well mixed;

Sentry ISOLOK API-PE – Probe sampler used in-line employs an electric actuator for applications in which pneumatics are not available, and is ideal for installing where product is well mixed.

Features

1.All samplers provide a consistent fixed volume, employ a scotch yoke design, and feature next generation seal design;

2.Standard rate of 20 samples per minute; faster rates available;

3.Available in standard 316 stainless steel wetted materials or Super Duplex steel for superior performance in demanding sediment or hydrogen sulfide applications;

4.ATEX rated and complies with API 8.2, ISO 3171 and ASTM D 4177 standards;

5.Flow-through, bottom discharge design (API-CA and API-CE);

6.Probe lengths accommodate 4- to 52-inch diameter pipes (API-PA and API-PE).

Hydrocarbon liquid sampling solutions

The Sentry® ISOLOK® API (anvil piston instrument) automatic sampler suite o¬ffers four distinct solutions to optimize sampling accuracy and repeatability for hydrocarbon liquids such as crude oil, condensates, and oil and water mixtures.

Representative samples are needed for quality control, to determine product properties and composition, and for cale calculations, allocations and loss control. In addition to complying with custody transfer standards such as API 8.2 and ASTM D 4177, the advantages of representative sampling include:

• Higher return on investment

• Better loss control

• Lower operating costs

Sentry API samplers provide consistent performance over a wide range of applications and conditions. While other samplers use simple linear motion with limited mechanical advantage, Sentry API samplers uniquely apply a scotch yoke mechanism to create linear movement – similar to a car engine. With few application limits, Sentry API samplers can be used in nearly any temperature or environmental conditions, offerring electrical actuation choices for applications where there is no air line available, and pneumatic actuation choice for where there is.

Sentry API samplers are ideal for: Sentry API

•Custody transfer of crude oil and condensate

•Upstream production, trading, transport and re ning of crude oil and condensate

•Chemical and petrochemical applications.

Features & benefits

Sentry API samplers offer superior performance and a long life, minimizing maintenance, accessories and service time needed. All provide a consistent fixed volume, employ a scotch yoke design, feature next generation seal design – and are easy and less costly to maintain than other solutions. Features include:

•Standard rate of 20 samples per minute; faster rates available

•Optional diamond-like carbon (DLC) coating

•Available in standard 316 stainless steel wetted materials or super duplex steel for superior performance in demanding sediment or hydrogen sul de applications

•ATEX rated ATEX认证

•Complies with API 8.2, ISO 3171 and ASTM D 4177 standards

•Flow-through, bottom discharge design (API-CA and API-CE)

•Probe lengths accommodate 4- to 52-inch (102- to 1,321-mm) diameter pipes (API-PA and API-PE)

With consistent performance over a wide range of process applications, environmental conditions and temperatures, Sentry API samplers offer the following benefits as a highly accurate, fixed volume automatic sampling solution:

•More reliable, robust and easy to maintain for hydrocarbon custody transfer by upstream crude oil suppliers, refiners and traders

•Easy to implement with a wide performance range at competitive prices for system integrators

•Flexible and able to be used in-line or in the center of a pipe or tank for refinery, chemical and petrochemical users

Options & accessories

In addition to our four Sentry API four sampling solutions, optional hydrocarbon liquid sampling complements and accessories are available:

Sentry COS sampler controller

•Easy to use ATEX rated safe area controller

•Touchscreen interface and simple menu system

•Quick access to frequently used parameters

•Choice of operating modes: time proportional or flow proportional; automatic or manual

•Up to 20 samples per minute standard

•Analog or pulse flow meter inputs

•On-display alarm indicators

Receivers

•Atmospheric receivers and optional level gauge

•High accuracy, integral, independent weigh scales for receivers

•Constant pressure cylinders

•Custom enclosures to suit

•Receiver switchover

Static mixers

•Four-inch and greater pipe diameters

•Effective mixing Low pressure drop

Insertion & retraction tools

•Four-inch and greater pipe diameters

•Hydraulic actuation

•Insert and retract up to 5,000 psig (345 bar) of line pressure

Receiver mixing skids

•Positive displacement pump

•Receiver sizes built to suit

•Built-in static mixer and sample port

•Receiver accessories

entry manual and automated sampler products and systems are designed and manufactured for taking safe, representative samples in nearly any application. Sentry sampling solutions are easy and cost-effective to implement, use and maintain.

Sentry

About the company

Sentry deliver true representative sampling and analysis techniques to customers around the globe, empowering them to accurately monitor and measure processes for improved production efficiency, output and safety. Running an efficient operation isn’t easy. By effectively conditioning, sampling and measuring gas, liquid, slurry, powder, solids, steam or water within their production environments, our customers obtain the critical insights they need to control and optimize their processes.

石油圈

石油圈