Critical to delivering onboard operations offshore is the drill riser, which provides a conduit for the drill string and drilling fluids from the ocean floor to the rig.

However, this has significant weight, which must be supported by its own structure and ultimately by the drilling vessel.

After pioneering the introduction of commercial syntactic foams in 1957, the need to reduce a drilling riser’s net weight in water and ensure that the structure and drilling vessel are supported led to Trelleborg supplying the first syntactic riser buoyancy modules for use in oil drilling in the Santa Barbara Channel in 1969. The marine riser buoyancy technology, specifically termed drill riser buoyancy modules (DRBM), for the next decade, achieved every new deepwater drilling record as depths reached up to 9,000 feet.

As such, Trelleborg was awarded a Pioneering Technologies Award at the 2015 Ocean Star Gala event in Houston, Texas. Awarded for its significant contribution to drilling technology for marine riser buoyancy, Trelleborg now joins a select group of companies in the prestigious Offshore Energy Center Hall of Fame.

“To be recognized for our pioneering work in the use of syntactic foam buoyancy in offshore drilling applications is a huge honor for Trelleborg,” said Alan Burgess, president for Trelleborg’s offshore operation. “We were responsible for innovating the use of syntactic foams for marine buoyancy applications, and these are still widely used in today’s most demanding offshore drilling applications. We are very proud to be the only syntactic foam buoyancy manufacturer to be invited into the Offshore Energy Center Hall of Fame.”

Established in 1989, the Offshore Energy Center is dedicated to increasing awareness of the energy resources available beneath the world’s oceans and to record the unique heritage and technological accomplishments of the industry that discovers, produces and delivers these resources.

The Pioneering Technologies Award recognizes important technologies and the development of those technologies by individuals, companies, organizations and institutions in the fields of offshore technology. The center’s Hall of Fame recognizes people and technological innovations that stand out in the development of the offshore industry and its resources.

Drill Riser Buoyancy Module

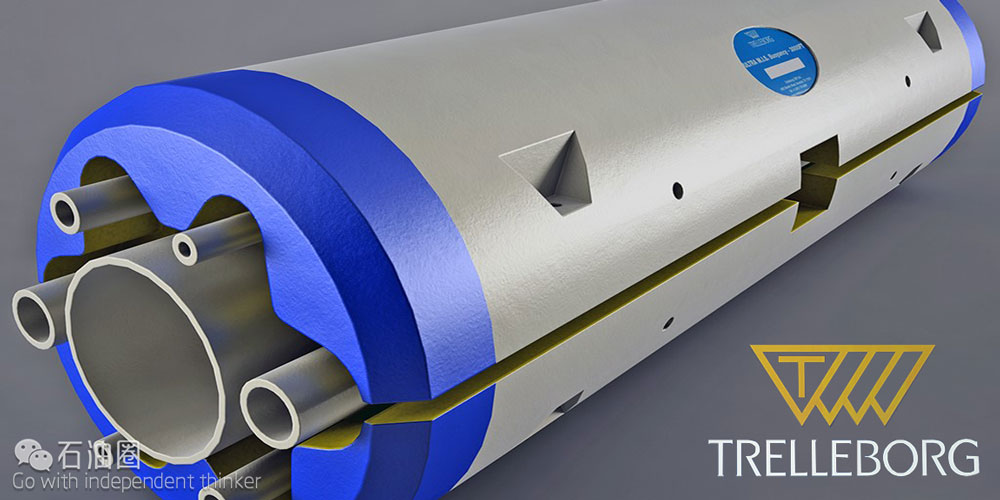

Drill Riser Buoyancy Modules (DRBM) are fitted along the length of the riser to reduce the weight of a drilling riser to a manageable level. Reducing this weight is critical in expanding exploration and resource recovery for ultra deepwater fields.

Depth range

Module densities provide uplift for riser in saltwater depths up to 12,000 ft.

Syntactic foam core

Low density syntactic foam comprised of a combination of hollow composite microspheres and macrospheres to provide uplift.

Molded recesses

Design includes recesses to accommodate fastening hardware and auxiliary lines of drill risers.

Fiberglass exterior skin

Tough exterior skin provides excellent abrasion and impact resistance to avoid damage in handling and installation.

Technical specifications

As an aid to drilling operations and to ensure installation at the correct depth, each buoyancy module is color coded according to the chart below. Both ends are painted and a matching color identification label is attached to the side of each module.

In offshore drilling operations, the drill riser provides a conduit for the drill string from the ocean floor to the rig. However, this adds significant weight which must be supported by its own structure and ultimately by the drilling vessel. Reducing overall weight in water to a manageable amount is critical in expanding exploration and resource recovery to ultra deepwater fields.

Trelleborg Offshore offers Drill Riser Buoyancy Modules (DRBM) to safely overcome these operational challenges. The DRBMs are fitted along the length of the riser to reduce the weight of the drilling riser to a manageable level. We work with our customer at all stages of the project life cycle to ensure all project requirements are met or exceeded.

Drill Riser Buoyancy operates in the harshest of marine environments. These challenging conditions can have a detrimental effect on Drill Riser Buoyancy resulting in cracked or broken buoyancy elements. To safely mitigate these hazardous conditions, Trelleborg Offshore developed the Ultra M.I.S. (Module Integrity System) range of Drill Riser Buoyancy. The Ultra M.I.S. system is a safety system which ensures a damaged buoyancy element can be safely recovered and repaired and also provides a significant increase in mechanical strength to ensure robust and reliable performance

Benefits:

• Enhanced safety – Ultra M.I.S.

• Increased mechanical strength

• Optimized uplift

石油圈

石油圈