CannSeal公司凭借其环形封堵概念获得2016国际油井干预和连续油管协会(ICoTA)就油井干预技术奖的提名。CannSeal环形封堵技术不仅作业简单,仅需采用电缆进行单次下入作业,而且工具的外形尺寸以及密封剂的粘度、流变性的参数可以依据客户需要进行调整。CannSeal技术的出现,为油井干预领域的发展开辟了新的篇章。

由于CannSeal公司的环形封堵概念,国际油井干预和连续油管协会(ICoTA)宣布CannSeal与其他三家公司一道被提名年度油井干预技术奖,该奖项在业内享誉盛名。

ICoTA的年度油井干预技术奖用于表彰在油井干预领域的技术创新或技术应用。新技术应用在降低风险、增加产量、提高安全性或减少环境影响等方面的卓越效果应得到充分证明。CannSeal创新性解决方案可成功的对环空中的泄露点进行隔离,高效解决油气井开发过程中的井液渗漏问题。

CannSeal研发负责人兼顾问Gunnarsson解释道,“ ICoTA评选委员会是以为客户提升资产价值为准则进行筛选,所以我们从现有众多技术中脱颖而出。同时,CannSeal技术还参加了为期两天的会议,并向石油协会中其他重要伙伴提交了相关技术资料。

CannSeal环形封堵技术石油圈原创www.oilsns.com

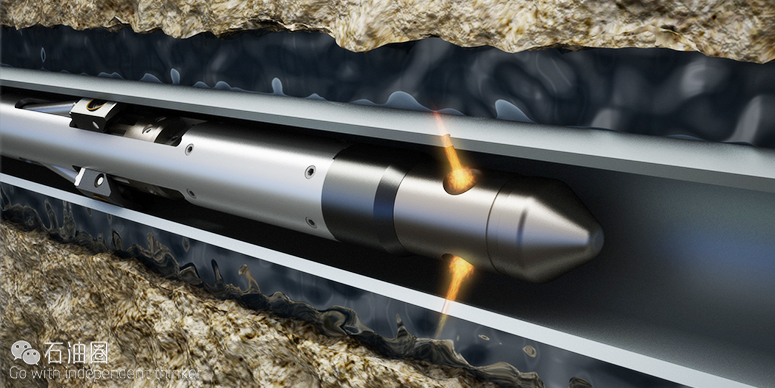

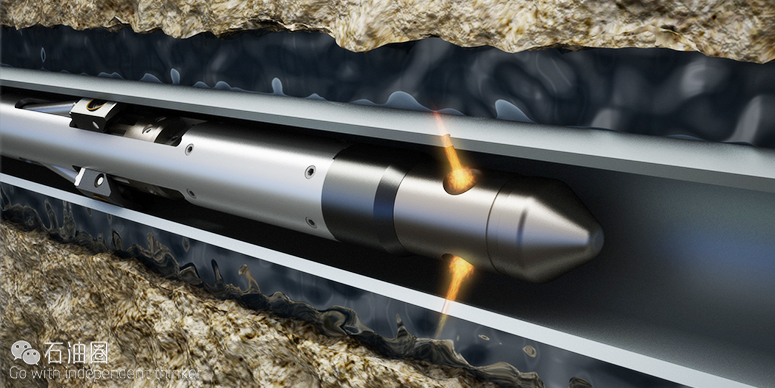

CannSeal是一项专门用来进行环空隔离而特定研发的新技术。该工具由一台标准的单芯电缆下入,到达目的层后注入环氧密封胶,形成环空封堵,环空封堵将会提供持久密封效果。上述全过程仅需单次电缆入井作业。

在单次作业中,作业人员先对套管进行射孔,然后向射孔区环空注入高黏性密封材料,形成环氧密封套,进而实现目的层成功隔离。环氧密封胶特殊的流变性能可以使其注入过程中横向流入套管环空区域,甚至可以在砾石充填完井作业中进行注入。注入该材料后,还可以挤压进入水泥塞未溶解的气孔中。环氧密封胶的固化受井底温度影响较大,因此需要在陆上进行预混合处理。

CannSeal工具由单根电缆下入,并且井内与工具参数可以通过客户定制的交互界面进行传输。该工具外径为3.3″,可以在4 1/2”-7”套管或油管进行作业。不包括密封剂储存器,工具标准长度为9.6m。密封剂存储器可以按照客户要求进行建造,外径尺寸范围是3.3″-4.0″,长度尺寸最长可以到14m。

CannSeal服务商依据设计者要求,在井下注入环氧密封剂,为井下环空提供持久密封。环氧密封剂的相对粘度、流变性能、密度等参数可以根据客户的井况需求,进行量身定做。

对于已经完成密衬套、套管和滤网下入后的井液泄露问题,最有效的解决方案是采用环氧密封剂固化一环形封隔器进行补救。在油气井开发或封堵与弃置(P&A)过程中,环氧密封剂也可以量身定制修补油气井的密封层完整性。

CannSeal技术应用实例

层位封隔石油圈原创www.oilsns.com

- 套管与地层之间的环空内

- 砾石充填井中

- 防砂筛管完井作业

- 套管环空中

油气井完整性石油圈原创www.oilsns.com

- 封隔器泄露补救措施

- 水泥封堵微孔修复

- 助力油气井封堵与弃置(P&A)作业

- 将储层与压力区逐层隔离

- 在储层上部进行环空封堵

- 在开始钻单个或多个分支井前,可以在井筒内用于封堵作业

- 在离线操作后,对环形隔离层进行补救

关于CannSeal石油圈原创www.oilsns.com

CannSeal位于欧洲北部的挪威,是一家致力于技术发展的石油服务公司,该公司已经掌握了一项具有自主产权的环形隔离技术,该技术主要用来提升油气井采收率。该公司是由AGR集团分拆出来的,目前为EDS集团、Statoil、Sumitomo三家公司共同持有。

来自/CannSeal 译者/赵金成 编辑/Lemon

The Intervention & Coiled Tubing Association, ICoTA announced that CannSeal was nominated as one out of four companies for the prestigious Annual Intervention Technology Award for its annular plug concept.

The criteria to be nominated as finalist states the following: “ICoTA International’s Annual Intervention Technology Award recognizes outstanding technical innovation or application of technology for well intervention. The application of the new intervention technology or technique should demonstrate; reduced risk, increased production, improved safety or minimized environmental impact. ”

CannSeal’s innovative solution is capable of providing a pin point isolation of the annulus, to effectively reduce unwanted water flow.

Prior to the judge election, Mr Gunnarsson, solution advisor and head of R&D, had explained the ICoTA Board of Directors how CannSeal technology distinguish itself from existing technology, and emphasized the added value to the clients assets. CannSeal also participated on the two days conference, presenting the technology to important players in the oil community.

The CannSeal e-line tool conveys the premixed epoxy sealant to the target area. In a single run, the tool operator perforates through the tubing, and injects the high viscous sealant material into the annulus forming an epoxy donut, capable of zonal isolation. The proprietary epoxy sealant is unique with rheology behavior allowing it to be injected in an open or cased hole annulus with crossflow, or even to be injected into gravel pack completions. It can also be used to squeeze epoxy into a cement micro annuls. Solidification of the epoxy is stimulated by the well temperature. and is premixed at onshore location.

The CannSeal technology

CannSeal™ is new technology that is developed specifically for annular isolation. The tool runs on a standard electrical mono-conductor cable, and the annular plug will provide a durable seal after being injected and placed at the predefined location. This is all done in one single wireline operation.

The CannSeal Tool

The CannSeal tool is run on electric line with online monitoring of well and tool parameters through our customized graphical user interface (GUI). The tool has an outer diameter of 3.3 inch and can operate inside 4 1/2″ – 7″ tubing or casing. Standard tool length without sealant canisters is 9,6m meters. Sealant Canisters will be custom built on request from customer within the range of OD 3.3″ – 4.0″ and a maximum length of 14 meters.

The CannSeal™ service allows a designer epoxy to be deployed downhole to provide a durable annular seal.

The Epoxy sealant can be tailor made to any well application in relation to viscosity, rheology and density.

The treatment effectively seals off unwanted fluid x-flow behind liners, tubing and screens by placing a solid external annulus packer.

The sealant can be tailored to function as a remedial integrity barrier during well production or as a component within a P&A operation.

Examples of CannSeal Applications using the CannSeal proprietary epoxy sealing technology;

- In an open annulus between casing and formation.

- In a gravel packed well.

- In a well completed with sand screens.

- In a cased hole annulus.

- Remedial repair of leaking packers.

- Repair of micro annulus in a cement matrix.

- Support to Plug and Abandonment, P&A activities;

- Annulus support for circulating in Cement, Sandaband, ThermaSet, or similar placement.

- Isolate individual pressure zones or reservoirs.

- Place annulus plugs on top of reservoir.

- May be used in combination with plugging of one well bore prior to drilling one or more new branches.

- Cement sealant to repair micro annulus.

- Remedial annular barrier to assist offline operations.

About CannSeal

CannSeal is a Norwegian-based, technology-focused, oil service company that has developed a proprietary annular isolation technology for enhanced oil recovery.The company is a spin-off from the AGR Group and is currently owned by EDS Group, Statoil, and Sumitomo.

未经允许,不得转载本站任何文章:

-

- Demons

-

石油圈认证作者

- 毕业于中国石油大学(北京),化学工程与技术硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系Demons(QQ2582825239;微信15810965891)

石油圈

石油圈