Tier 1 Energy Solutions has entered into an exclusive partnership with Delphian Ballistics Inc. Led by Stuart McLeod, Paul Lynch and Serena Arif, Delphian Ballistics has an absolute focus on improving well productivity by building a better perforating system.

TriStim is Delphian’s unique and patented technology that harnesses the power of shockwaves to deliver a bigger, cleaner and deeper perforation. Tier 1 Energy will be the exclusive service provider of Delphian’s TriStim technology in Western Canada.

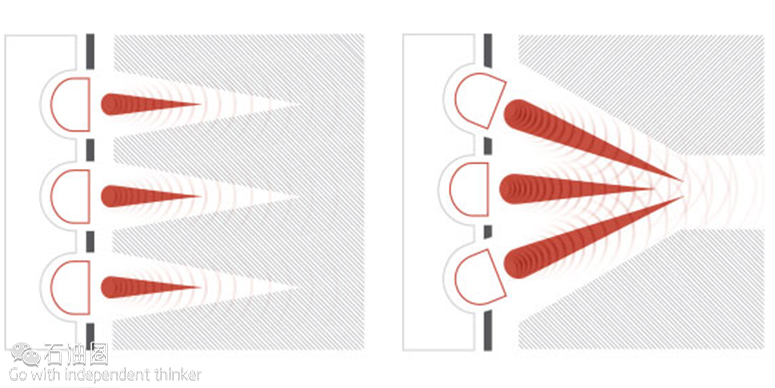

TriStim offers a smarter way to perforate because it sets out to do something unique based on the physics of ballistics. By applying precision ballistics engineering to the age old process of perforating, TriStim is able to offer significant improvements in well productivity and enhanced fracture dynamics by harnessing the power of shockwaves. TriStim uses three shaped charges in concert. Not just one shaped charge, as with conventional perforating systems. The triple charge convergent configuration makes TriStim unique.

“TriStim is a differentiating technology responding to the current global market needs of maximizing production whilst reducing overall costs. We need to be selective of who we collaborate with to achieve our goals, and we’re delighted to be partnered with Tier 1 Energy for the Western Canada market,” Stuart McLeod, managing director of Delphian Ballistics, said.

Introducing TriStim

The TriStim convergent perforating system rethinks the age old process of perforating by offering a unique configuration where three charges collaborate in unison to deliver a bigger, cleaner and deeper perforation.

This improved charge geometry harnesses the power of the three convergent shock waves to create a perforation that has less perforation induced formation damage, whilst also significantly improving inflow from the well.

TriStim is better at creating more optimised tunnel geometry than conventional perforating systems and better geometry leads to increased flow. Combine this better flow with greatly reduced skin damage during the perforating process and you have significantly increased production.

TriStim can be deployed in any scenario requiring precision perforating and the system is currently at work in pre-frac, production and reperforating campaigns all over the world.

The TriStim gun system is simple because it can be deployed in the wellbore using all of the methods commonly used for conventional perforating: electric wireline, jointed tubing, coiled tubing or slick line.

With standard perforation gun sizes of 2″, 2⅞”, 3⅛” and 4½”, the TriStim product range is designed to address the vast majority of customer requirements and the system can be run by any service company.

No extra preparation work is required by customer staff, compared with a conventional perforating programme. More information in the TriStim Product Specification.

Assembling TriStim is easy, and we even have online training available for your gun assemblers.

TriStim uses standard components

Despite its unique patented shaped charge arrangement, TriStim only utilises fully field proven components so there is no risk from using untested parts.

TriStim has taken the present standard of oil & gas well perforation systems and innovated using standard components. From the shaped charges to the gun hardware itself, TriStim is no different to any other premium perforating system.

TriStim has undergone rigorous testing

Additionally, TriStim has been developed to ensure no compromises in the performance that would be expected from a standard perforating system.

This means TriStim has the same shot density and shaped charge capacity as any comparable system. Keeping TriStim aligned means there can be no reduction in the overall performance of the gun system – only upsides due to the advantage of convergent shockwaves.

TriStim is configurable

As a bonus, TriStim can deliver even more upside when the phasing of the convergent perforation channels is fine tuned according to specific well conditions. This enables even better performance from the perforation.

Whether used for new wells, reperforation or for pre-frac applications, TriStim is the perforation system with the potential to take your completion to the next level.

In summary, the key factors supporting TriStim’s successful deployment are as follows:

- Conventionally run guns

- Standard components

- Rigorous testing

- Global logistics excellence in oil & gas related explosives

- Careful well selection

- Meticulous planning

- Full gamut of support on tap

- A Delphian specialist on the frontline, onsite, in the crucial initial stages

Technical benefits

As you might expect, different applications and different situations reap different combinations of benefits. But all can benefit from TriStim’s key technical benefits.

Less skin damage:

The objective for any perforation system is to establish an effective hydraulic communication between the wellbore and the formation (reservoir). Unfortunately, the processes involved in drilling & completing oil & gas wells have the unavoidable consequence of inducing damage to the near wellbore region.

TriStim has been specifically designed to deliver successfully in each of these four areas:

- Optimised combined tunnel geometry

- Reduced perforation damage effects

- Optimised reservoir coverage

- Maximised depth of penetration

In summary, TriStim will deliver a tunnel that has the best possible penetration to the reservoir because of how it focuses on reducing the effects of perforation skin damage.The SPE paper demonstrates that ‘TriStim® convergent perforations show improvements to flow efficiency by up to 25%, skin reduction of up to 85%. PI is shown to increase by circa 50% over the standard HSD system.’

Optimised perforating tunnel geometry:

TriStim also delivers greatly improved perforating tunnel geometry. Not simply deeper penetration and increased tunnel volume, but also a cleaner tunnel with greatly reduced perforating skin.

In conventional perforating, the rock is plastically deformed – in effect, pushed out of the way. The result? A compressed and damaged formation that leaves a crushed zone of reduced permeability. Impeding flow.

With TriStim’s 3-charge arrangement, shock waves from the upper and lower charges combine to weaken the rock in the focal region of the tunnel axis. Shock waves from the middle charge deliver an altogether different effect. The consequence of this is rubblisation, no crushed zone and deeper penetration.

As a bonus, the combined shock waves deliver a pulverising effect which means that the weakened material is rubblised/pulled apart resulting in no crushed zone effect in the region where the shock waves converge.

- 85% Increased perforated area

- 3x’s (300%) Increased perforation tunnel volume

- 10% Increased penetration

Reduced fracking initiation pressure:

The perforation often provides a vital connection to the reservoir for the effective initiation and propagation of a Hydraulic Frac. Applied “pre-frac” in tight plays, TriStim facilitates a significant reduction in Hydraulic Fracture initiation pressure, as well as significantly improving fracture placement control. Such benefits mean reductions in horsepower, manpower, water & chemicals, leading to increased NPV and the potential to access stranded resources that would otherwise not be exploited。

Benefits for unconventional wells:Reducing the fracture initiation pressure means savings in horsepower, manpower, water, chemicals, equipment and logistics. Once again the knock-on effects can be major. For example:

- Savings in well construction costs due to lower fracture pressure and the potential to perform more fracs per well, opening access to previously stranded resources.

- Savings in water offsetting transportation bottlenecks and other causes of shortage.

- Savings in chemicals, water and other materials, plus reduced logistics requirements, adding up to reduced environmental footprint and a good PR story.

石油圈

石油圈