近年来,非常规油气和海洋石油开发如火如荼的进行着。与常规油气田开发相比,非常规和海洋油气田的井况更为复杂,开发难度更高。以墨西哥湾为代表的深海油藏尤其如此,深水油藏的压力与温度都远远高于其他油藏,常规的技术在此并不适用,针对此种难题,各大油服公司都加码了深水开发技术的研发。

本篇文章为大家带来的是哈里伯顿的深水压裂技术MaxForce Flow Ultra-Kleen射孔技术,该技术能够在极端压力和温度条件下进行压裂和完井作业,并获得了2015年World Oil Award提名。

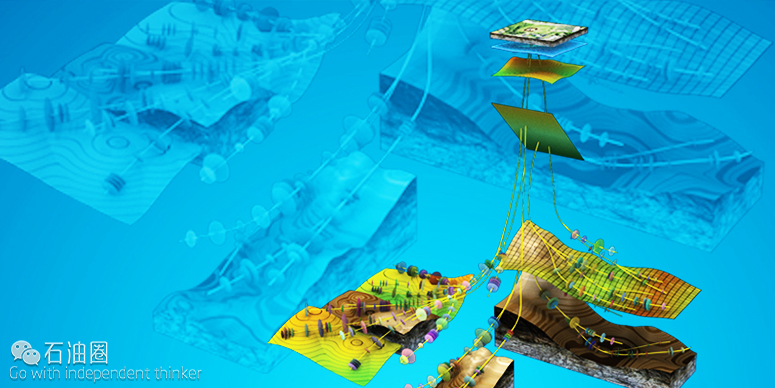

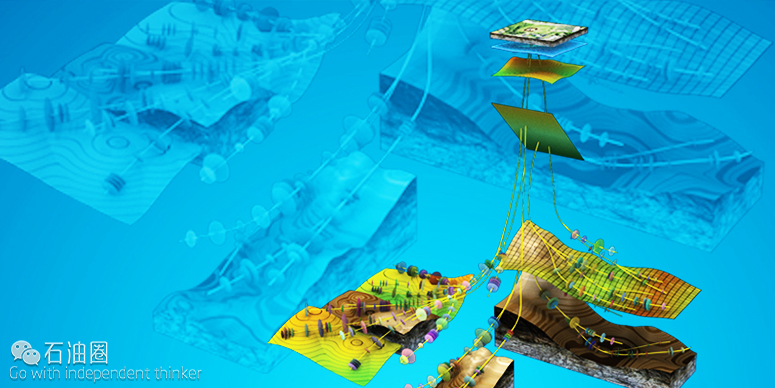

MaxForce Flow Ultra-Kleen深水压裂技术

哈里伯顿公司的射孔技术MaxForce® Flow UltraKleen能够满足复杂井况下的射孔作业要求,该系统的动态过程控制对井下射孔设备实时监控井下条件变化。射孔设备额定作业压力和温度分别是25000psi和425°F,毫无疑问,它是为深水和高压下作业的最佳选择。

MaxForce系统包括UltraKleen和Low Debirs Zinc两部分,每部分各有一个扩展的6.75英寸流动面积和18孔/英寸的孔密。流通面积增加能够有效提高常规的和基于流量的完井方案,最大限度地提高流动面积能减少通过孔眼的压降和每个砂粒上的作用力,从而减少筛管冲蚀和出砂可能性。当然,这些改进都是在不影响厚壁套管的打捞能力前提下进行的。

MaxForce Flow Ultra-Kleen系统采用独特的电子管设计,即使在大狗腿和大斜度井中也能完成不产生碎片的作业,这种特性有助于减少从射孔产生的碎屑,确保电子枪系统安全、射孔清洁而不影响射孔区液体流动。同时,该系统也能降低射孔中动态的瞬间作用力,保障了完井和射孔管柱的油管传输。

随着官方认可的API 19B第1和5的测试顺利通过,MaxForce Flow Ultra-Kleen射孔设备无论是在孔尺寸和最低碎屑量方面都在引领行业。它提供13.04sq.in./ft的高流通孔道面积,在9 7/8英寸62.8磅/英尺C-125套管测试,和16克/立方英尺的最低碎屑,这给予了最佳的压裂充填完井。该射孔设备的设计可以防止射孔过程中的动态瞬时的冲击负荷,这保护了完井和油管输送射孔管柱的过程。

产品优点石油圈原创www.oilsns.com

- 射孔过程中和射孔后排出的碎屑量最少

- 压力等级高,适合深水压裂作业

- 射孔的流量区域达13.04 sq. in./ft

- 射孔过程中瞬间作用力降低

- 通过减少压降和穿孔流量降低筛管冲刷的风险

- 降低液体和气流紊乱几率,降低出砂风险

- 降低射孔之间的压力,降低孔道坍塌风险

- 在不牺牲的打捞能力前提下最大化射孔枪作业能力

典型应用范围石油圈原创www.oilsns.com

MaxForce Flow Ultra-Kleen系统的压力等级更高,能完成更复杂井况的压裂、完井作业,主要覆盖范围如下:

- 为特殊作业条件提供一个有效的射孔方案,集中在:深水压裂,防砂完井,压裂完井,砾石充填,压裂充填,高速堵水完井以及普通完井

- 可在无机械分离设备存在的前提下降低关于出砂处理的潜在费用

- 可消除射孔碎屑有关的潜在问题

案例分析:深水极端条件下完成射孔作业

MaxForce® Flow Ultra-Kleen的射孔设备在墨西哥湾完成了一系列的射孔作业,只产生了少量的射孔碎屑,孔道的流通面积非常理想,满足了客户在超过21000psi的极端井况下的作业期望。

在墨西哥一个深水开发商,面对深水高压井的挑战,需要在井底压力在超过21,000 PSI、深度超过30,000英尺的总垂深(TVD)条件下实施射孔方案。在这种极端的井下条件,普通射孔方法并不适用。

该运营商对于射孔设备在射孔过程中施加在完井管柱上的动态瞬变负载十分关注,射孔系统的压力不能超过其它井下工具和设备的压力等级限制。此外,该运营商还需在射孔过程中产生最大的孔道流量面积,同时控制在裂缝充填过程中可能会导致操作问题的碎屑产生。

射孔段在垂深为30710英尺至30815英尺,作业环境压力位245°F的温度和压力21174 psi。该MaxForce Flow Ultra-Kleen射孔设备运行成功,压裂效果非常理想。射孔枪点火后,作业人员对井况进行监测,反排液在振荡器上没有发现碎屑。

沉砂封隔器在管道上的原始标记处重新标记,射孔枪被拉出洞口,没有任何运动和填充的迹象。完井和油管输送的射孔管柱被取回到地面没有任何事故(如卡住,弯曲等)发生。整个工作的完成没有跟生产无关的时间(NPT)或安全问题。

通过与运营商有效的沟通和策划,该任务最重成功执行。MaxForce Flow Ultra-Kleen射孔设备为这些极端条件下的井成功射孔,同时满足所有客户的期望,并解决他们的所有问题。

作业挑战石油圈原创www.oilsns.com

- 因为其井底压力超过21000psi,射孔总垂深超过30,000英尺,运营商担心在射孔过程中其他井下工具和设备超过压力限制和动载荷;

- 作业者需要能产生最大的流动面积同时不产生碎屑的射孔设备,用来提高和保证压裂充填过程可以在没有生产无关时间下完成。

解决方案石油圈原创www.oilsns.com

- 利用压力等级为25,000 PSI,规格为6¾-in 18- SPF 的 MaxForce Flow UltraKleen射孔设备进行射孔作业。该设备是哈里伯顿专门为深水和高压井压裂设计,并配备有动态控制系统来处理动态载荷问题;

- The MaxForce Flow Ultra-Kleen射孔设备提供了业内最大的孔道流动面积和最低碎屑量,确保压裂充填完井的最佳环境。

作业结果石油圈原创www.oilsns.com

- 射孔设备按设计运行,防止射孔过程中动态瞬时载荷过大,保障完井和油管输送射孔管柱的安全;

- 井底钻具组合(BHA)一从井筒取回就进行检验确认,无事故(卡钻,弯曲等)发生,且振荡器上无杂物发现。整个工作按照设计在没有产生非生产时间和安全问题下成功完成。

来自/Halliburton 译者/徐建鹏 编辑/Lemon

The MaxForce® Flow Ultra-Kleen Perforating Technology was selected as a finalist for the 2015 World Oil Awards.

The MaxForce® Flow Systems consist of UltraKleen and Low Debirs Zinc, each with an increased flow area of 6¾-in. 18-spf. The increased flow area enhances both conventional and flux-based completion approaches. Maximizing the flow area reduces the pressure drop across the perforations and the effective force on the individual sand grains, resulting in less screen washouts and less potential for sand production. This is all without sacrificing fishing ability in heavy wall casings.

The high-pressure rating of the MaxForce Flow System is ideal for:

- Deep water

- Sand control completions

- Stimulation completions

- Gravel pack, frac pack, or high-rate water pack

- Natural completions

With a proprietary charge tube design, the 6¾-in. 18-SPF MaxForce® Flow Ultra-Kleen System family provides an almost debris-free operation, even in severe doglegs and high-angle wells. The 6¾-in. 18-SPF Big Hole MaxForce Flow Ultra-Kleen System helps ensure that debris created from shaped charges is minimized, containing larger debris pieces within the gun system for safe, clean perforating without sacrificing flow area. The system also reduces dynamic transient forces during the perforation event, which safeguards the completion and tubing-conveyed perforating string.

Benefits

- Has the lowest amount of debris that exits the carrier during and after the perforating event

- High-pressure rating that is suited for deep water

- Delivers high-flow area of 13.04 sq. in./ft

- Reduces dynamic transient forces during the perforation event

- Reduces risk of screen washout by reducing pressure drawdown and flow rate per perforation

- Reduces risk of sanding production due to drag from fluid or gas turbulence

- Reduces risk downhole for mechanical problems related to charge debris during stimulation treatments

- Shot phasing that limits stress contrast and helps prevent tunnel-to-tunnel stress failures

- Maximized gun size without sacrificing the ability to fish in heavier wall casings

Applications

- Provides an exceptional effective perforation solution focused on: – Deep water – Sand control completions – Stimulation completions – Gravel pack, frac pack, or high-rate water pack – Natural completions

- Can eliminate potential costs associated with sand production without mechanical segregation techniques

- Can eliminate potential issues associated with perforating debris

CASE STUDY

MaxForce® Flow Ultra-Kleen Gun System delivers unsurpassed flow area with lowest gun debris in the Gulf of Mexico

A Gulf of Mexico operator, facing a deepwater high-pressure well challenge, needed a perforating solution to perforate at bottomhole pressure greater than 21,000 psi (1,448 bar) at a depth of more than 30,000 ft (9,144 m) total vertical depth (TVD). Under these extreme downhole conditions, standard perforating solutions were not an option. The operator was concerned about the dynamic transient load that a gun system could exert on its completion string during the perforating event. The perforating system could not exceed the pressure limitations of other downhole tools and equipment. The operator also needed a gun system that produced maximum flow area and limited debris that could cause operational issues during the frac-pack operation.

The operator approached Halliburton for a solution. The Halliburton Global Engineering and Technology team designed and modeled a unique solution to meet these challenges. Halliburton’s innovative 6¾-in. 18-SPF Big Hole MaxForce® Flow UltraKleen Gun System, designed with Dynamic Transient Control, was the solution. The gun system is rated to 25,000 psi (1,724 bar) and 425°F (218°C). It was designed for optimum performance in deepwater and high-pressure wells, allowing Halliburton to perforate the well within the limits of operator’s requirements. With a confirmed official API 19B Section 1 and 5 Test, the MaxForce Flow Ultra-Kleen Gun System leads the industry both in hole size and lowest debris. It delivers a high-flow area of 13.04 sq. in./ft, in a 97 /8-in 62.8 lb/ft Q-125 casing test, and lowest debris of 16 g/ft, which allows for the best frac-pack completion. The gun’s system design prevents shock loading from dynamic transient forces during the perforation event, which protects the completion and tubing-conveyed perforating string.

The perforated interval was from 30,710 ft (9,360 m) to 30,815 ft (9,392 m) MD, and had a temperature of 245°F (118°C) and pressure of 21,174 psi (1,460 bar). The MaxForce Flow Ultra-Kleen Gun System fired and functioned successfully. After the guns fired, the well was monitored and reversed out. No debris was spotted on the shakers. The sump packer was retagged at the exact original tag mark on the pipe. With no indication of movement and fill, the gun was pulled out of the hole. The completion and tubing-conveyed perforating string were retrieved to surface with no incidents (i.e., sticking, bending, etc.), with physical confirmation of all shots fired and minimum lost debris as designed. The entire job was also completed with no nonproductive time (NPT) or safety issues.

Through effective communication and planning with the operator, the job was successfully executed as proposed. The MaxForce Flow Ultra-Kleen Gun System successfully perforated the well under these extreme conditions, while meeting all the client’s expectations and addressing all their concerns.

CHALLENGES

- With its bottomhole pressure greater than 21,000 psi (1,448 bar) and perforation depth at more than 30,000 ft (9,144 m) TVD, the operator was concerned about exceeding pressure limitations and the dynamic loading of other tools and equipment downhole during perforation event.

- Operator required a gun system that would produce maximum flow area and, at the same time, be debris free to enhance and ensure the fracpack operation could be completed without NPT.

SOLUTIONS

- The 25,000 psi (1,724 bar) 6¾-in 18- SPF Big Hole MaxForce Flow UltraKleen Gun System was utilized. This system was developed for optimum performance in deepwater and high-pressure wells, and designed with Dynamic Transient Control to address dynamic loading concerns.

- The MaxForce Flow Ultra-Kleen Gun System was selected for its delivery of the maximum flow area and lowest debris in the industry, ensuring the best environment for frac-pack completions.

RESULTS

- The gun system performed as designed to prevent shock loading from dynamic transient forces during perforation event, safeguarding the completion and tubing-conveyed perforating string.

- Confirmation of the bottomhole assembly (BHA) was done upon retrieval from the wellbore. No incidents (i.e., sticking, bending, etc.) occurred. No debris was spotted on the shakers. The entire job was completed successfully as designed with no NPT or safety issues.

未经允许,不得转载本站任何文章:

-

- Demons

-

石油圈认证作者

- 毕业于中国石油大学(北京),化学工程与技术硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系Demons(QQ2582825239;微信15810965891)

石油圈

石油圈