Halliburton introduced the Spectrum Real-Time Coiled Tubing Services on 22 March at the 2016 SPE/ICoTA Coiled Tubing & Well Intervention Conference & Exhibition in Houston. This suite of services is designed to deliver more accurate and more complete downhole measurements with better reliability.

The Spectrum services comprise two offerings: Spectrum Diagnostic Services and Spectrum Intervention Services. These services integrate Halliburton’s coiled tubing with downhole measurement tools, fiber-optic sensing and telemetry to deliver complete and accurate real-time data. Operators are better able to minimize uncertainty, assess reservoir performance and monitor wellbore conditions, helping to significantly improve well intervention operations and production.

“Whatever is happening downhole, you can see on location at surface, while you are completing the job,” Eric Holley, Product Line Manager, said during a press event at the conference. “We can actually watch completion stimulation efficiency in real time. We can monitor what is happening downhole and articulate that back to the operator to tell them how effective those stimulations have been.”

Spectrum Diagnostic Services delivers fiber-optic distributed sensing through coiled tubing to assess well productivity and completions effectiveness by identifying fracture initiation points across the wellbore and profiling production. An alternative to traditional production logs, the services can monitor a time series of data across the entire wellbore as opposed to single snapshots in time. Applications for these services include determining stimulation cluster efficiency, fracture mapping, production profiling, leak detection and assessment of wellbore integrity.

SPECTRUM Intervention Services Optimizes coiled tubing well intervention by providing critical real-time data from a customizable bottomhole assembly (BHA). Unlike standard coiled tubing jobs where surface-measured parameters, such as pipe weight and circulating pressure, are the only available data, SPECTRUM Intervention Services delivers real-time subsurface insight from where the treatment is being applied, along with data from the surrounding downhole environment.

“The focus is understanding how we can use fiber-optic enabled coiled-tubing data to accelerate the engineering learning curve,” Mr Holley said. “What we mean by that is, how we can take actual downhole data and evaluate it, and be able to make decisions on the next well to improve overall stimualtion design and overall production performance,” he said.

SPECTRUMSM Diagnostic Services

RESERVOIR, WELLBORE, AND TREATMENT ASSESSMENTS THROUGH REAL-TIME, FIBER-OPTIC DISTRIBUTED SENSING

SPECTRUMSM Diagnostic Services delivers coiled-tubing-conveyed, fiber-optic distributed sensing to assess reservoir performance and completions effectiveness by monitoring fluid movement across the entire wellbore and visualizing treatment efficiency in real time.

OVERVIEW

SPECTRUM Diagnostic Services utilizes coiled-tubing-conveyed, fiber-optic distributed sensing for real-time evaluation of completion and production effectiveness. This service leverages fiber-optic distributed temperature sensing (DTS) and distributed acoustic sensing (DAS) measurements to monitor fluid injection and profile production along the entire length of the wellbore. An alternative to traditional production logs, SPECTRUM Diagnostic Services, through coiled tubing, can be conveyed to total depth (TD) in order to simultaneously monitor several time series of data for evaluation, as opposed to single snapshots in time. For example, shut-in DTS data can provide information regarding the location of fracture initiation points, while steady-state flowing results can be used to determine production profiling.

APPLICATIONS

- Stimulation cluster efficiency

- Production profiling

- Injection profiling

- Leak detection

- Well interference

- Frac diversion design optimization

- Gas lift optimization

BENEFITS

» Provides analysis along the entire length of the wellbore

» Can improve well performance with real-time treatment optimization

- Delivers well production profile assessment on new or existing wells

- Can identify well integrity challenges to sustain long-term production

- Visualizes cluster efficiency across the wellbore through per-stage analysis

FEATURES

- Distributed temperature sensing (DTS)

- Distributed acoustic sensing (DAS)

HOW IT WORKS

Optical fiber cables can be installed inside several coiled tubing sizes, depending on the specific intervention requirements. SPECTRUM Diagnostic Services coiled tubing is deployed to the bottom of the well. The data gathered downhole is then transferred up the optical fiber to the surface acquisition system. At surface, data can be viewed in real time, using Halliburton’s FiberViewTM software platform. DTS provides a thermal profile, tracking temperature response over time to evaluate real-time fluid distribution across the entire well. DAS technology adds an acoustic survey of the wellbore, providing a complementary result to characterize flow paths in the well, further enhancing analytic capabilities. The wellbore can be cleaned out as the coil is being run in the well. When combined with SPECTRUM Intervention Services, it is possible to achieve, in a single trip, wellbore evaluation and downhole tools intervention optimization, such as milling, perforating, or setting packers.

ADVANTAGES

By leveraging fiber-optic data, SPECTRUM Diagnostic Services can monitor the entire wellbore, vertical or horizontal, with high-precision spatial resolution to determine both stimulation fluid distribution and production contribution – in most cases, within a single run.

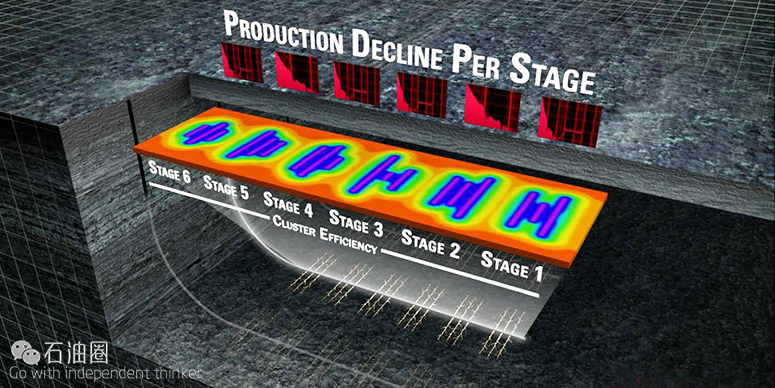

Cluster spacing is a critically important parameter that all operators focus on during the completion phase of a well. However, validation of actual performance is rarely available. Once a frac job has been completed, the DTS and DAS analysis allow operators to gain insight into the effectiveness of the stimulation treatment through the visualization of fluid movement into the perforations, and to compare those results along the wellbore. SPECTRUM Diagnostic Services provides valuable insight at per-stage resolution levels. This can enable customers and subject matter experts to benchmark completion practices and to optimize well performance based on accurate downhole data.

SPECTRUMSM Diagnostic Services,Evaluates Fracture Effectiveness,Leading to Lower Completions Costs

SPECTRUMSM DIAGNOSTIC SERVICES IDENTIFIES IMPROVEMENT IN STIMULATION CLUSTER EFFICIENCY

OVERVIEW

As more operators in unconventional basins adopt chemical diverting technology as part of their stimulation treatments, operators have been focused on achieving optimum cluster completion efficiency. Cluster efficiency describes the percentage of clusters that receives effective stimulation for a given interval. Previously, there were limited methods available to provide accurate and consistent data to evaluate the entire length of the wellbore. SPECTRUMSM Diagnostic Services quantifies fracture initiation points across the wellbore, validating the effectiveness of a fracture treatment.

A major operator used SPECTRUM Diagnostic Services to evaluate two wells that had been completed with unique stimulation designs. One well was treated with AccessFrac® Stimulation Service, and the other was stimulated with a standard customer design. SPECTRUM Diagnostic Services was deployed after each stimulation treatment. The fiber-optic analysis determined that, by using diverter technology, greater stimulation cluster efficiency was achieved and the completion design was optimized by reducing the number of intervals in the well.

CHALLENGE

The operator had two cemented lateral wells (Well A and Well B) on the same pad that were completed using different stimulation techniques. Well A was completed with 20 stages, using a hybrid fracture design with diverter technology. Well B was treated with 28 stages, using a similar fracture treatment, but no chemical diverter was employed. The operator needed a method to determine the relative effectiveness of treatment across the wellbore and the impact of diversion on stimulation performance.

SOLUTION

SPECTRUM Diagnostic Services was used to assess the fluid distribution across each well and to determine the optimum stimulation treatment. Fiber-optic distributed temperature sensing (DTS) and distributed acoustic sensing (DAS) results helped evaluate the stimulation cluster efficiency of each well 40 days after the wells had been treated. For each well, all stimulated intervals were evaluated simultaneously in a single trip, providing reliable evaluation of cluster efficiency in real time.

RESULTS

Data acquired after the wells were completed indicated that the number of fracture initiation points for Well A was 20 percent greater than those for Well B. The operator was able to lower stimulation costs, reduce time spent completing the well by pumping fewer stages, and achieve better well performance based on the insights gained from SPECTRUM Diagnostic Services.

石油圈

石油圈