ACTive Q service delivers fluid velocity measurements to expand coiled tubing downhole monitoring capabilities

Schlumberger today introduced the ACTive Q* CT real-time downhole flow measurement service, which delivers real-time injection diagnostics and treatment evaluation in just one run in a well.

“Fluid injection monitoring and placement often requires customers to reach conclusions through trial and error or time-consuming logging operations,” said Amerino Gatti, president, Well Services, Schlumberger. “With the ability to measure pressure, temperature and fluid velocity in real time during interventions, the ACTive Q service improves our customers’ understanding of downhole wellbore and reservoir behaviors while intervention is ongoing. This helps facilitate customers’ decision making and improve the effectiveness of treatment placement.”

With the ACTive Q service, customers and Schlumberger can evaluate the flow rate contribution to each interval, review the data in real time and adjust the pumping schedule as needed for diversion and subsequent stimulation stages.

The ACTive Q service has provided real-time flow measurement information for several operators in the Middle East, North Africa and Central America.

ACTive Q service

ACTive Q service couples real-time fiber-optic telemetry and thermal transfer flow measurements for onsite matrix treatment evaluation and real-time treatment diagnostics in just one run in the well. The service enables operators to evaluate the flow rate contribution to each interval, assess the zonal coverage achieved during the treatment, and decide whether to further adjust the stimulation schedule to optimize the treatment outcome.

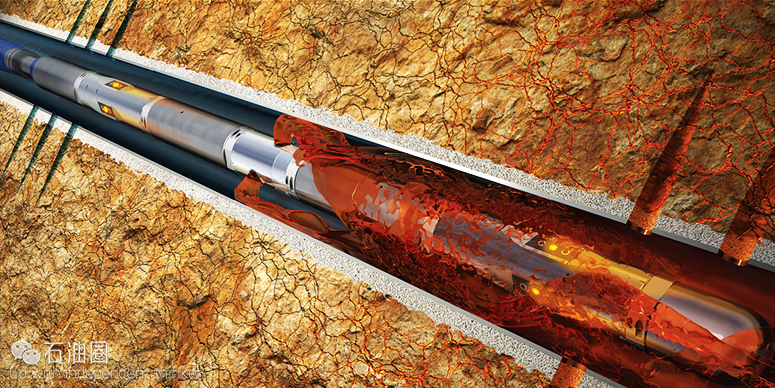

ACTive Q service acquires high-quality flow data using the ACTive DFLO CT real-time flow measurement tool, which comprises two sensor arrays that monitor the fluid’s velocity as it travels around the tool.

Achieve greater success during well interventions

The versatile ACTive Q service provides high-quality downhole flow monitoring data and is complemented by the robust ACTive DFLO CT real-time flow measurement tool. These measurements facilitate decision making and improve the effectiveness of treatment placement by providing operators with highly accurate information.

As part of the ACTive Q* real-time flow measurement service, the ACTive DFLO* CT real-time flow measurement tool provides downhole fluid velocity measurement and direction detection in real time while maintaining pump-through capability.

The measurements are conveyed to surface on CT with real-time fiber optic telemetry. Effective in a wide range of downhole environments,the ACTive DFLO tool provides additional feedback on the effectiveness of the intervention. In particular, the tool helps track the direction that the fluid takes due to the reservoir’s response to the treatment. Intervention parameters such as pumping rates, injection depth, and fluid volumes can be adjusted with increased confidence, because they are based on the real-time downhole information provided by the ACTive DFLO tool and input into the Techlog* wellbore software platform.

Combining ACTive DFLO tool readings with other ACTive services measurements—such as pressure, temperature, gamma ray, casing collar location, tension compression, or DTS—enhances the effectiveness of real-time CT services. The combined monitoring of those critical downhole and distributed parameters improves the understanding of the treatment as it progresses, and in turn, increases the effectiveness of ACTive services.

As an alternative to complex interventions that include production logging tools for simple postjob evaluation profiles, or profiling before and after a specific treatment, the ACTive DFLO tool can also profile flows across a producing or injecting interval to better inform decisions on treatment options.

APPLICATIONS

- Fluid injection profiling

- Fluid placement control

- Leak detection

- Treatment effectiveness monitoring

- Diversion confirmation

BENEFITS

- Enables accurate, efficient fluid placement by providing downhole flow monitoring data in real time

- Evaluates treatment effectiveness quickly, so adjustments can be made without delay

- Reduces operational time by enabling a wide range of CT services to be used in the same run

FEATURES

- Real-time fluid direction detection and flow velocity measurement

- Robust design with: high compressive load,no centralizers or arms,no spinners or protruding elements,resistance to H2S, solvent, and acid,flow-through capability,ball-drop compatibility, Modular design for different configurations, Full compatibility with ACTive* real-time downhole coiled tubing services

- Accurate depth control with integral casing collar locator

- Optional gamma ray measurements

- Pressure and temperature sensors to monitor treatment

- Fast-rate telemetry

- Compatibility with distributed temperature sensing (DTS)

Kuwait Oil Company Decreases Wellhead Injection Pressure by 1,000 psi with ACTive Q Service

Improve declining injectivity of water injector well

A water injector well in the Sabriya field in Kuwait exhibited falling injection rates over time. This was accompanied by an increase in injection wellhead pressure, which was negatively affecting the pressure support for other producer wells. Because blindly bullheading treatment fluid from the surface had only minimally improved injection rates in the past, Kuwait Oil Company (KOC) wanted to identify and target sections of the interval that needed stimulation or diversion. KOC had previously used traditional logging solutions, but it was interested in using newer technology that would save time and eliminate additional runs to obtain the needed information.

Identify and target intervals with real-time flow measurement services

The ACTive Q service identified two primary thief zones, located at the heel and toe of the well. It also indicated that the middle section was not taking any fluid. Having this information allowed KOC to focus the treatment, using coiled tubing to spot acid along the middle section while leaving the toe and heel untouched. Because the ACTive DFLO tool is resistant to acid, engineers were able to monitor and adjust pumping of the treatment fluid while the stimulation was in progress.

Enhanced injectivity while reducing expenses and intervention time

Using accurate real-time flow data to target the stimulation treatment substantially improved the wellhead injection pressure from 1,000 psi to zero psi, with a constant injection rate of 8 bbl/min [1.27 m3/min]. In addition, the ability to combine real- time flow monitoring, injection profiling, and acid stimulation in a single run significantly reduced costs by eliminating three days of operations that would have been required to acquire information with spectral noise logging. Compared to traditional bullheading, the customized strategy saved fluid resources and also prevented the overstimulation of the major intake zones.

RESULTS

- Reduced the wellhead injection pressure from 1,000 psi prestimulation to zero psi poststimulation, with a constant injection rate of 8 bbl/min [1.27 m3/min];

- Improved injectivity after acid stimulation and achieved a more uniform injection over the 2,400 ft [731.5 m] of the horizontal openhole section;

- Performed preprofiling, stimulation, and postprofiling in a single run, which mini- mized costs, enabled fast decision making, and improved operational turnaround time.

石油圈

石油圈