新型高科技复合材料制成的电缆重量更轻、尺寸更小,拥有更好的电气性能,能够承受更高的环境温度,且没有忽视安全性。

编译 | 二丫

HUBER+SUHNER公司用RADOX材料开发出一种电子束交联的高性能化合物,可以满足某些极端的海上需求。该技术已经通过了DNV、ABS、BV、CCS等船级社的认可与认证。

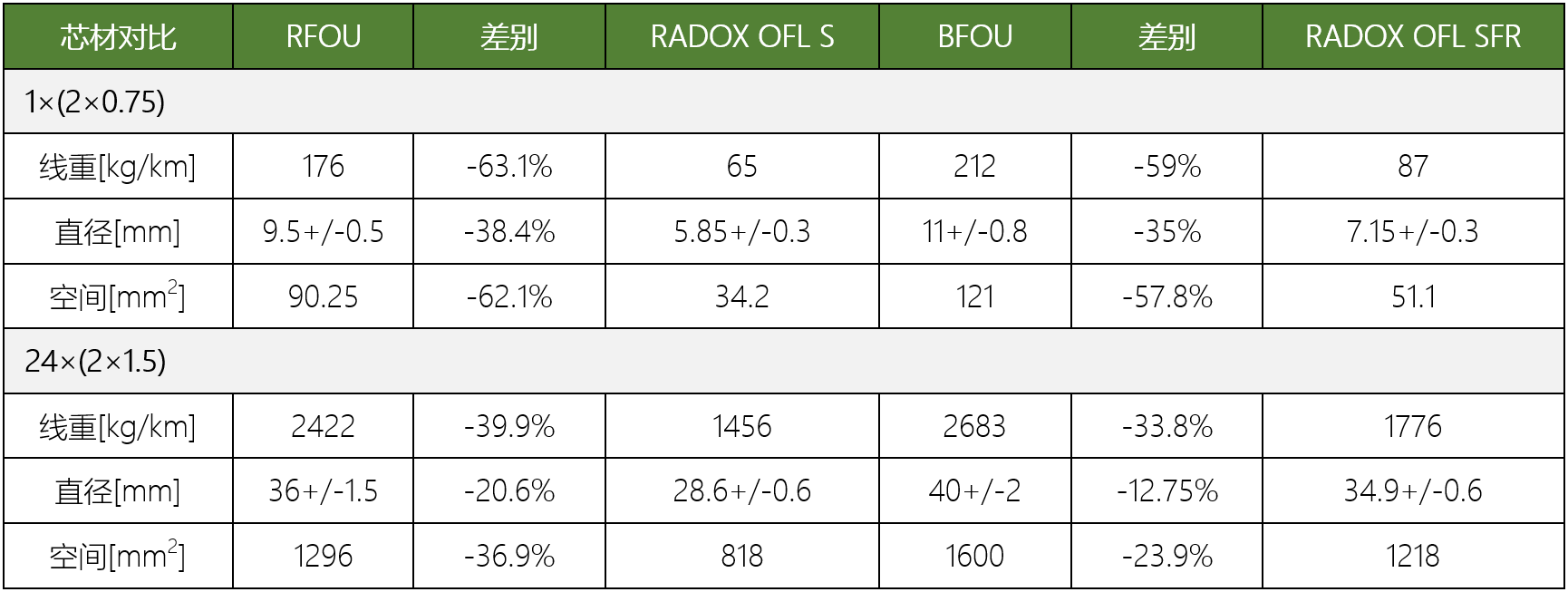

小重量、小体积

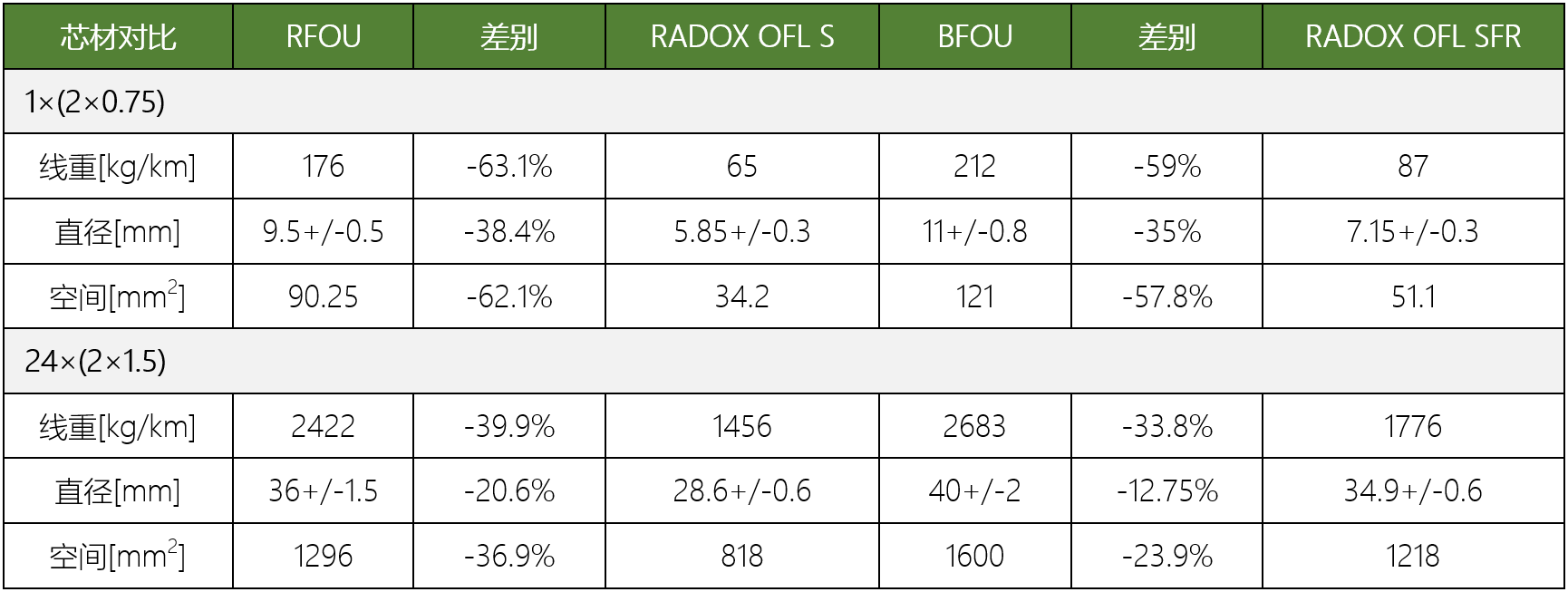

所有RADOX电缆都由电子束交联而成,拥有最高的机械强度以及很高的耐候性。与RFOU/BROU相比,RADOX OFL的线重降低了65%(平均50%),从而可减轻数吨的重量。

安装成本低廉

与现有的海上电缆相比,RADOX所需的剥线时间缩短了60%。此外,由于该材料具有良好的柔韧性,电缆可轻松地穿过困难通道,在数百米范围内走线。若需要安装数十公里的电缆以及数百条干线和支线,这就相当于节省了很多天的安装时间。

降低电缆配件成本

该电缆的直径更小,可以减少所有电缆配件(如电缆密封套、电缆托架与电缆梯架)的使用量,大幅降低海上项目的成本。而且在节省成本、重量与空间方面,该电缆的优势也很明显。此外,RADOX电缆不存在冷流现象,所以不需要使用电缆衬垫。

寿命更长

所有RADOX电缆均采用高端复合材料进行护套与芯线绝缘,电子束交联结构提供了最高的机械强度,并具有极强的耐温、耐水、耐泥浆、耐腐蚀性。与耐温90℃的标准海底电缆相比,耐温120℃的护套与145℃的芯线,将该电缆的使用寿命延长了8倍。

RADOX® OFL电缆适用于油气行业,兼具柔韧性与轻量性

与标准RFOU/BFOU相比,RADOX OFL电缆在重量、空间、使用寿命、恶劣环境下的安装与作业方面具有显著优势,大幅降低了总体拥有成本(TCO),可用于所有海上平台。

适用范围

1、适用于固定式与移动式设备;

2、干燥、潮湿的地方;

3、船内外、海上平台、FPSO以及其他工业设备;

4、耐油、耐泥浆、耐液压油(符合NEK606:2016标准);

5、零下40℃至120℃的连续作业温度;

6、阻燃(IEC60332)和耐火(IEC60331)。

特点

1、薄壁设计,重量减轻33-63%;

2、通过IEC/DNVGL-CP-0400轻量级项目认证;

3、创新型辐射交联结构的RADOX护套,将使用寿命延长了8倍;

4、双股、三股、四股电缆的横截面积分别为0.75、1.5、2.5平方毫米;

5、即使多达48个双股也非常柔韧;

6、坚固耐用的高端聚醚醚酮材质芯线,适用于高温应用,例如蒸汽锅炉;

7、符合NEK606标准。

近年来,海上作业面临更严峻的挑战,需要技术改进以更有效地作业,并确保更高的安全性。电缆往往会影响施工、安装与长期作业。因此,该产品的使用寿命必须有助于降低总体拥有成本(TCO)。RADOX OFL电缆是实现这一目标的先进解决方案。

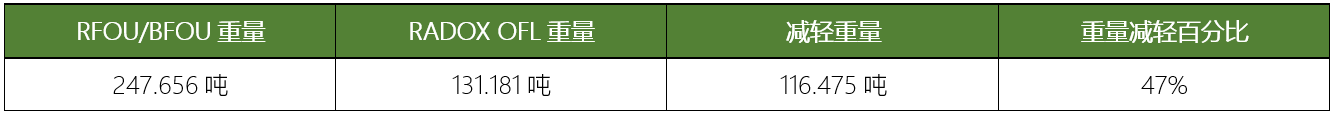

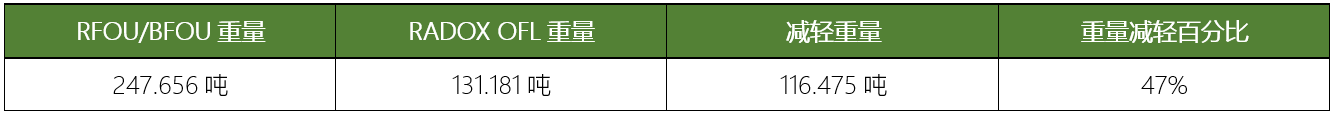

下表展示了标准RFOU/BFOU(总长608千米)电缆与RADOX OFL电缆的对比。平均而言,RADOX OFL可以使该项目的总重量减轻47%,从而在钢结构上节省超过500万美元:

RADOX OFL电缆采用了新型材料与先进设计,尤其是在安全性方面,具有显著优势:

1、不存在冷流现象,无需使用电缆衬垫,因此可以凭借单个压缩电缆密封套,实现长期密封;

2、聚醚醚酮材质是蒸汽/热油加热、蒸汽锅炉等工艺应用的理想材料。仪表仓的温度通常高于80-90摄氏度,这会缩短EPR的使用寿命。造成的绝缘脆性会导致短路或错误地测量作业参数;

3、作业者面临的另一个安全风险是电缆暴露于液压/齿轮油中,随着时间的流逝,这些油会造成密封套膨胀,进而导致密封套破裂。RADOX OFL电缆能很好地处理液压/齿轮油。RADOX PEEK的内部线芯可以承受液压油/齿轮油,并作为辅助密封来避免发生任何事故;

4、可安全用于移动设备,例如海上起重机或锚链,使用次数可高达100万次。

For English, Please click here (展开/收缩)

RADOX® OFL Instrumentation cables

New high-tech plastic compounds allow the development of cables that have lighter weight and smaller dimensions while providing better electrical values, withstanding higher ambient temperatures without neglecting the safety aspect.

With its RADOX material, HUBER+SUHNER has developed an electron-beam crosslinked high performance compound that meets these extreme Offshore requirements. This has been approved and certified by classification bodies such as DNV, ABS, BV, CCS and others.

Lowest weight and smallest space requirements

All RADOX cables are fully electron-beam cross-linked for the highest mechanical strength and extreme resistance against mud and weather. Compared to RFOU/BROU, RADOX OFL will reduce the weight up to 65 % (average 50 %), and thus save several tons of weight.

Lowest installation cost

RADOX is proven to require 60 % less stripping time compared to today’s Offshore cables. In addition, its flexibility allows the cable to be run more easily over many hundreds of metres even through difficult passages. Where installations may require many tens of kilometres of cables and hundreds of main and branch lines, this amounts to the saving of many days of installation time.

Reduced cable accessory costs

With the reduction in the diameter of the cable, all cable accessories, such as cable glands, cable trays and cable ladders, which can be extremely expensive for Offshore applications, will be reduced. This provides further benefits in terms of additional savings on cost, weight and space. Additionally, RADOX cables have no problems of cold-flow as no bedding is required.

Lifetime guarantee

All RADOX cables use high-end compounds for sheath and core insulation and are fully electron-beam cross-linked to provide the highest mechanical strength and are extremely resistant against temperature, water, mud and corrosion. The 120 °C sheath and 145 °C cores enhance the lifetime of the cable by a factor of 8 compared to standard 90 °C Offshore cables.

RADOX® OFL Instrumentation cables Oil&Gas, flexible and lightweight

RADOX OFL cables apply to all offshore topside applications with outstanding low Total Cost of Ownership (TCO) in terms of weight, space, lifetime, installation and handling of harsh environmental conditions compared to standard RFOU/BFOU.

Application areas:

- For fixed and moving application

- Dry, damp or wet locations

- Inside and outside ships, offshore platforms, FPSOs and other industrial equipment

- Resistant against oil, mud and hydraulic oil (NEK606:2016 Cat. a-d)

- -40 °C to + 120 °C continuous operating temperature

- Flame retardant (IEC60332) and Fire resistant (IEC60331)

Highlights:

- Thin wall design to reduce weight between 33 % and 63 %

- Approved by IEC/DNVGL- CP-0400 lightweight class program

- Innovative radiation cross-linked RADOX sheath enhance lifetime by factor 8

- Pairs, triples and quadruples with cross-sections 0.75, 1.5 and 2.5 mm2

- Very flexible even with up to 48 pairs

- Ruggadised high-end PEEK cores for high temperature process applications, e.g. steam bolier.

- NEK606 compliant

The requirements in the offshore market are becoming increasingly demanding in the last years. Improvements are needed to run operations more efficiently and with higher safety. It affects engineering, installation and long-term operations. The lifetime of a product must contribute to a low Total Cost of Ownership (TCO). RADOX OFL cable is the advanced solution to achieve this target.

Below numbers show a recent instrumentation cable package where RADOX OFL was compared with standard RFOU/BFOU (total length 608km). On average RADOX OFL could have reduced the total weight by 47 % in this project and thus save more than USD 5 million in steel structure:

With new innovative materials and different designs, RADOX OFL cable offers huge benefits, especially safety improvement:

未经允许,不得转载本站任何文章:

石油圈

石油圈