本期技术动态,共更新6项国际前沿技术信息。

编译 | 二丫

油气工程是决定油气勘探发现、提高产量、实现经济开发重要的决定条件。油气工程投资约占据上游投资的60%,油气工程技术及装备的水平决定了可开采资源量及开采的经济性,其在增储上产、降本增效、推进油气勘探开发转型升级方面正扮演着举足轻重的作用。

——石油科技论坛

水平井实现一趟钻

斯伦贝谢近期发布了NeoSteer钻头,可提供更高的造斜能力,可增加弯曲段与水平段的钻进速度,从而提高水平井的钻进效率。NeoSteer ABSS是一款为油田量身定制的解决方案,它利用数字技术,将最新的井眼轨迹控制算法与机器学习和数据分析技术相结合,可为客户提供更好的设计方案与作业效率。在北美与阿根廷的非常规油藏中,NeoSteer ABSS已经应用250余次,共钻进了260万英尺(792,480米)。其中,钻进速度最快的井位于DJ区块,在29小时纯钻进时间内,一趟钻完成垂直段、弯曲段与水平段,总进尺达到了15,123英尺(4,609.5米),平均机械钻速为523英尺/小时(159.4米/小时)。在DJ区块,SRC能源公司使用NeoSteer CL弯曲与水平ABSS,完成了“井工厂”12口井的弯曲段与水平段。针对Niobrara非常规页岩地层的不同区域,该客户能够将单口井的机械钻速提高20%,单井可节约多达21小时。

NeoSteer ABSS设计集成了独特的切削结构和导向机制

新型水泥头可提高安全性和作业效率

哈里伯顿的Commander全通径水泥头可用于实现旋转和往复运动,同时具有无线通信功能,可实现更强的水泥胶结效果和更优质的井筒完整性。基于专业的设计研发,Commander水泥头旨在将先进的技术和安全功能带入到以往受成本制约严重的非常规作业、水平井或偏远地区。该水泥头扭矩高达30,000 ft-lb,抗张强度700,00 lb,可配套4 1/2 in-6 in管段,平均仅需30分钟即可完成装配。旋转和往复运动功能可最大程度增加屏障覆盖范围,改善水泥胶结效果,并提高陆地作业效率。水泥头可以通过无线遥控盒启动套管刮塞,无需人工手动操作即可完成,有助于降低现场人员的风险。

到目前为止,哈里伯顿公司已经完成了超过100项任务, Commander全井眼水泥头,平均安装时间可达30分钟,减少了人员在危险区域的作业时间。

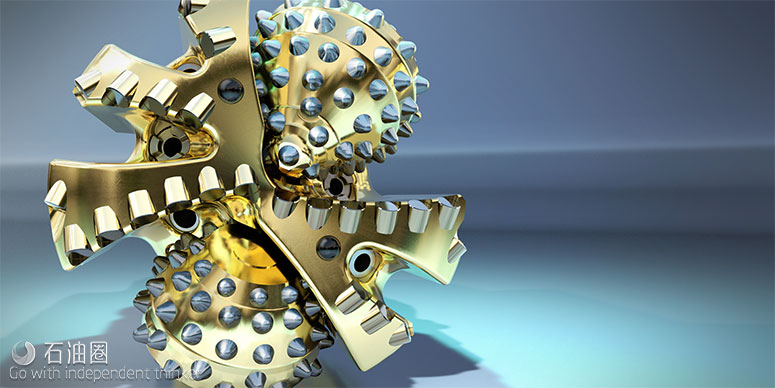

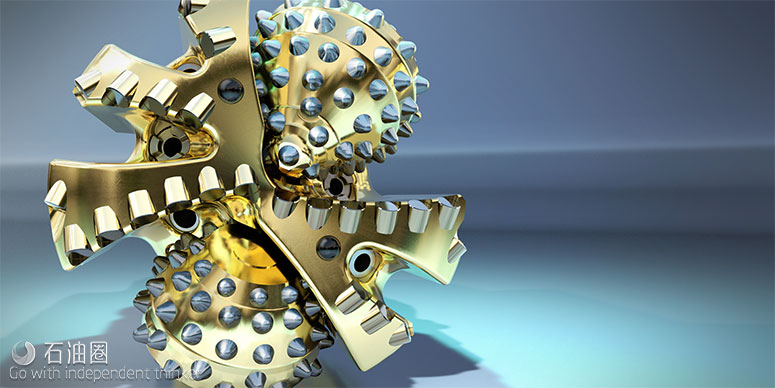

新型钻头可提供最佳钻进性能

贝克休斯发布了Kymera Mach 5混合钻头,该钻头旨在扩大混合钻头的应用范围,增加ROP,改善可操纵性,并在高性能钻探环境中提供更长的钻头寿命。为了提高钻速,新型钻头都在不断地引入高扭矩马达和更高的钻压,这样一来,如果想要在复杂作业环境中找到更合适的钻头,难度就变得越来越大。导向问题往往是引起中靶难度大,影响钻进速率的症结所在。而钻头的耐用性则在较硬地层和层间有硬条纹的夹层中受到限制。Kymera Mach 5 通过延长锥形结构,扩展了PDC和碳化钨刀片(TCI)的双重切削作用,从而提高了钻头耐用性和穿透率。用于Kymera Mach 5技术的分析模型平衡了TCI和PDC切削元件的啮合。这种特定于应用程序的建模可提供更有效的钻井动力学,最大程度提高转速和可操纵性。

Kymera Mach 5钻头拥有优质的PDC刀片,适用于恶劣的钻井环境,具有高热稳定性、低磨损率和优异的耐久性。

更坚固耐用的连续油管注入头

NOV目前已经将HR-6120连续油管注入头发布到其连续油管设备和技术产品组合中。据NOV介绍,经过工程设计后,Hydra Rig制造的新型注入头比之前的装置更坚固耐用、更更可靠,同时需要的维护更少,重量更轻。HR-6120注入头专为2 in至2 7/8 in连续油管管柱设计,能够满足连续油管淬火和回火的要求,包括NOV最新提供的先进热处理线圈(ATP-130)。新型注入头具有120,000磅的连续提升能力以及60,000磅的连续缓冲能力,同时能够通过低速控制实现140,000 psi设计压力下运行。此次设计升级包括注入头自动润滑系统、防滑系统和远程油管对准系统,同时还改进了驱动和牵引系统,提高了现场作业性能。

专为电缆部署ESP设计的降本阀门技术

Pragma公司推出了一种先进的井下安全阀,为安装在生产井中的电缆式的电潜泵(ESP)提供了一种改进的井控工具。新型阀门将保证陆上和海上的所有安装设备符合所有安全规定,同时通过优化时间、成本、人员和风险等因素来改善经常在安装和回收过程中的操作流程。Pragma的ESP安全阀是一种紧凑型设备,集成在ESP组件的下部,并在ESP作业的同时,通过生产油管进行部署和回收。与其他系统不同,该阀门通过在ESP和ESP封隔器之间进行安装,不依赖于老化的完井组件完整性。这种阀门的功能是基于压差或升力驱动装置,不需要压力室、液压控制线或电力,从而保证了可靠性。当ESP关闭时,阀门将自动安全关闭,并根据需要打开或关闭多次。另外,该技术也可应用于其他人工举升系统,包括毛细管柱举升、气举、螺杆泵和射流泵,同时也具备另一款耐高温版本。

创新的钻井供应链流程

据外媒报道,GoExpedi已与Ensign达成合作,为Ensign的钻机车队提供一项新技术。这项新技术将大大提升Ensign的供应链能力,以支持其全天候钻井作业。目前,Ensign已将GoExpedi确定为其电子商务、供应链及物流领域的合作伙伴。Ensign于今年8月1日开始推出新平台,并将在其整个钻机平台上进行扩展。从定制采购平台、零配件物流跟踪,到向Ensign的钻机交付最后一公里,GoExpedi将为Ensign提供端到端服务。

For English, Please click here (展开/收缩)

Drilling horizontal wells in a single run

Schlumberger has released the NeoSteer at-bit steerable system (ABSS) to improve horizontal well drilling performance by providing high-dogleg capability and increased ROP in the curve and the lateral, a press release stated. Developed as a fit-for-basin system, the NeoSteer ABSS leverages digital technologies by combining trajectory control algorithms and machine learning and data analytics to provide improved planning and execution performance. The NeoSteer ABSS has been used to drill a combined total of more than 2.6 MMft during 250 runs in the unconventional reservoirs in North America and Argentina. The fastest well drilled was in the Denver Julesburg (D-J) Basin and drilled shoe to shoe, vertical, curve and lateral totaling 15,123 ft in 29 on-bottom hours with an average ROP of 523 ft/hr. In the D-J Basin, SRC Energy used the NeoSteer CL curve and lateral ABSS to drill a 12-well pad targeting vertical curves and lateral sections in a single run. The operator was able to increase ROP by 20%, saving as much as 21 hours in a single well while targeting various zones in the unconventional Niobrara Shale formation.

New cement head offers improved safety and operational efficiency

Halliburton has released the Commander Full Bore Cement Head, which was designed to enable rotation and reciprocation, coupled with wireless capabilities, to deliver enhanced cement bonds and improved well integrity, according to the company. It is designed specifically to bring advanced technologies and safety features to cost-constrained unconventional operations, pad wells or remote locations. The cement head supports 4½-in. to 6-in. pipe sections, with up to 30,000 ft-lb of torque and 700,000 lb of tensile, and rigup can be accomplished in as few as 30 minutes on average. The rotation and reciprocation capabilities can help maximize barrier coverage to improve cement bonds and increase efficiency in challenging land-based operations. Wireless capabilities help reduce risk to onsite personnel, as workers do not need to be lifted to launch casing wiper plugs. Plugs can be launched via a wireless remote control box, and embedded wireless logic prohibits plugs from being launched out of sequence.

New drillbit provides optimized drilling performance

Baker Hughes has released its Kymera Mach 5 hybrid drillbit, which is designed to extend the hybrid bit application range, increase ROP, improve steerability and provide longer bit life in high-energy drilling environments, according to the company. The drive to improve penetration rates has seen the introduction of high-torque motors and higher weight on bit, making it increasingly challenging to find the right bit for a tougher operating environment. Steering issues make it difficult to land in the desired target and compromise overall penetration rates. Bit durability has been limited in harder formations and intervals with interbedded hard streaks. The cutting structure of Kymera Mach 5 expands the dual cutting action of the PDC and tungsten carbide inserts (TCI) by using extended cone technology for increased durability and higher penetration rates. The analytical modeling used for Kymera Mach 5 technology balances the engagement of TCI and PDC cutting elements. This application-specific modeling provides efficient drilling dynamics to maximize the penetration rate with steerability.

Coiled tubing injector for rugged reliability

National Oilwell Varco (NOV) has released the HR-6120 coiled tubing (CT) injector to its portfolio of CT equipment and technology. The new injector, manufactured by Hydra Rig, has been engineered to be more rugged and reliable than previous units while needing less maintenance and weighing less, according to NOV. The HR-6120 injector is designed for 2-in. to 27⁄8-in. CT strings and is able to handle the demands of quench-and-tempered CT, including NOV’s latest offering in advanced thermally processed coil (ATP-130). The new model has a 120,000-lb continuous lifting capacity, 60,000-lb continuous snubbing capacity and is capable of running 140,000-psi designs with slow-speed control (inches per minute). Upgrades include an injector auto-lubrication system, slip mitigation system and remote tubing alignment, while improved drive and traction systems increase field performance.

Cost-saving valve technology for cable-deployed ESPs

Pragma has released an advanced downhole safety valve to create an improved well control tool for cable-deployed electric submersible pumps (ESPs) retrofitted to production wells, a press release stated. The new valve will enable onshore and offshore installations to meet all safety regulations while improving the operational footprint at the well site during installation and retrieval by reducing time, cost, personnel and risk. Pragma’s ESP safety valve is a compact device, integrated within the lower portion of the ESP assembly and is deployed and retrieved through the production tubing in the same run as the ESP. It offers wellbore closure below the ESP control lines. By installing the valve between the ESP and ESP packer, the valve does not rely on the integrity of aged well completion components unlike alternative systems. The valve’s functionality is based on a pressure differential, or lift actuated design, requiring no pressurized chambers, hydraulic control lines or electrical power, which safeguards reliability. The valve will fail-safe close when the ESP is switched off and can be opened and closed as many times as required. The technology also can be applied to alternative artificial lift systems including capillary strings, gas-lift velocity strings, progressive cavity pump and jet pump systems. A high temperature version also is available.

Innovating the drilling supply chain process

GoExpedi has collaborated with Ensign to provide Ensign’s fleet of drilling rigs with a new technology that will significantly enhance its supply chain capability to support the company’s 24/7 drilling operations, a press release stated. Ensign has identified GoExpedi as a partner within the e-commerce, supply chain and logistics space. Ensign started the rollout of its new platform on Aug. 1 and will stage the expansion across its entire fleet of rigs. GoExpedi will provide Ensign with end-to-end services, ranging from the customized procurement platform, geotag tracking of parts to the last mile of delivery to the Ensign rigs.

未经允许,不得转载本站任何文章:

石油圈

石油圈