本月技术动态,共更新7项国际前沿技术信息。

编译 | 石油圈

近日,全球知名信息技术研究和分析公司Gratner发布了2019年影响油气行业的十大趋势,包括人工智能、可视化和自动化、网络物理资产系统等。

“数字化转型已经得到油气行业的公认,而通过采用人工智能、云计算和物联网等技术,一些企业已经取得了意想不到的疗效。”

——Simon Cushing, 高级分析主管,Gartner

企业合作为油气行业开启接地气的数据新视角

斯伦贝谢、雪佛龙和微软宣布三方合作,以加速石油技术和数字技术的创新(点击查看原文)。三方巨头强强联合,这在油气行业尚属首次。对任何企业来说,数据正迅速成为最有价值的资产之一,但由于这些数据信息又往往存在相互孤立的现象,因而从这些数据中提取见解认知往往很困难。作为合作的一部分,这三家公司将携手合作,在斯伦贝谢的DELFI勘探开发认知环境中为雪佛龙建立Azure-native应用程序,使公司能够处理、可视化、解释并最终从多个数据源获得有意义的见解。

DELFI是一个安全的、可扩展的、开放的基于云的环境,提供的勘探开发软件技术涵盖勘探、开发、生产以及中游领域。在微软的支持和指导下,雪佛龙和斯伦贝谢将结合他们的专业知识和资源,加速在微软的Azure中部署DELFI解决方案。各合作方将确保软件开发在安全性、性能和上线管理方面满足最新标准,并与开放的地下数据宇宙数据平台(Open Subsurface Data Universe Data Platform)兼容。此次三方合作将分三个阶段完成:首先是在DELFI环境中部署Petrotechnical Suite,随后在Azure上开发云原生(Cloud Native)应用程序,最后根据雪佛龙的目标,在E&P价值链上共同创新一套认知计算系统。

AI应用“机智”识别生产停机时间及过程风险

近日,贝克休斯和C3.ai公司共同对外宣布,推出BHC3 Reliability应用程序(点击查看原文)。这是由两家公司成立的合资公司BakerHughesC3.ai研发出的首款人工智能应用软件。该软件集成了深度学习预测模型、自然语言处理和机器视觉等功能,可以持续地收集来自公司传感器网络、企业系统、维护记录、管道和仪表装置的数据。利用来自全系统的历史及实时数据,BHC3 Reliability机器学习模型能够识别导致设备故障和流程混乱的异常情况,运营商可据此采取主动干预措施,减少停机时间和营收损失。BHC3 Reliability系统体系方法可部署在油气行业的所有部门,适用于陆地及海上平台、压缩站、炼油厂和石化工厂的资产维护和流程监控,减少停机时间,提高生产率。BHC3 Reliability人工智能应用程序由BHC3 AI套件提供技术支持,并基于贝克休斯针对油气行业的专业认知,通过故障预防和规范化操作等功能,进一步强化程序本身的预警功能。

新的海底节点技术可提供精确地震成像

CGG公司旗下的设备业务单元Sercel与BGP合作研发,于近日发布了新的海底节点技术—GPR。与传统传感器所收集的数据相比,GPR对地震成像数据的采集来自于Sercel的QuieSeis宽频数据传感器技术,使所收集到的数据更加精确精准。多年来,CGG一直致力于降低风险,提高客户进行油藏勘探开发的成功率。GPR技术的推出恰逢全球海底节点市场的持续增长和成熟期,将进一步强化CGG的产品和服务组合。新节点已成功完成海上试验,BGP的现场投入确保了GPR的性能符合行业要求。其设计紧凑,且具有高保真度和超静音性能,以及灵活的部署选项。

基于长期的合作伙伴关系和互补的地震专业知识经验,Sercel和BGP共同设计、研发并部署了GPR

针对海上施工、检验和修理的结构监测

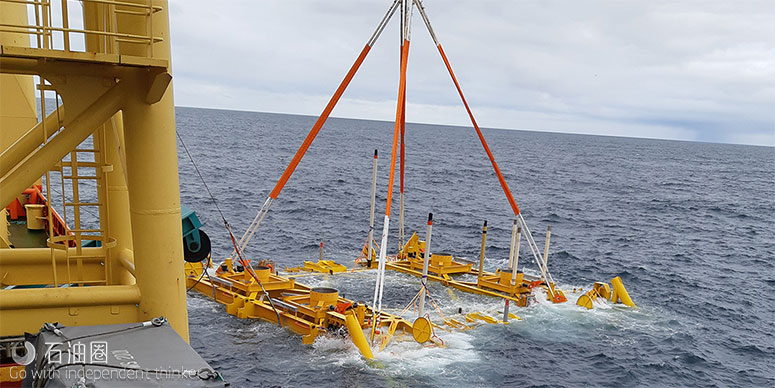

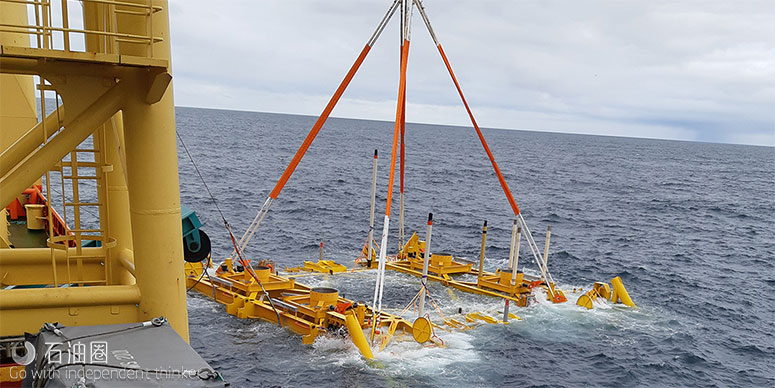

Ashtead Technology的集成化偏差监测系统DMS(Deflection Monitoring System)用于监控海底吸罐式海底结构的安装,能够实时监测、计算、显示和记录结构的偏差、朝向、间距、侧滚、深度以及吸罐压力差。这种实时监测方法对于及时发现潜在问题、降低结构损坏的风险至关重要。在最近为Ocean Installer AS公司部署的海底结构安装项目中,DMS系统经授权可进行独立性操作,将数据传输给水下安装机器人(ROV)。Ashtead利用测量传感器和定位工具以及技术来提高收集数据的准确性,确保系统性能的最大化。结构安装工程完工后24小时内,Ashtead公司为该项目中8个结构安装全部提供数据分析和安装报告。该项目用时25天,比原计划提前完成,产生了显著的成本效益。

数据管理系统(DMS),正在沉入大海,监测、计算和记录结构数据

新的分离器消除了钻井和完井过程中的有害物质

CP Energy Services公司称,该公司的Sand Commander是一款四向分离器,用于在完井钻井过程中分离有害物质,能够去除99%的有害气体和95%的砂子。这款分离器能够优化返排液处理,提高安全性,降低钻井成本,促进完井作业更环保。该分离器配备了改良过的垂直气体分离器,气体通过顶部排出。回流的液体经搅拌,以提高气体的去除效率,同时防止沙子在底部堵塞。其多料斗设计可以使流体的流动趋缓,促进砂子在经过挡板时能够沉淀下来。与此同时,该分离器第四个环节分离出来的水可以在现场重复使用,可用于钻井作业。

Sand Commander促进了环保型完井作业,并配备了液压控制、环保清洗罐和经改良的废气处理系统

克服无人机面临的检查挑战

Flylogix公司在一份新闻稿中表示,该公司已经与道达尔公司、美国国家航空交通管理局以及油气技术中心合作,启动了一项北海无人机计划。该项目旨在克服与北海无人机检查活动相关的挑战,并使商业无人机运营商更容易进入英国管理空域进行超视距(BVLOS)操作。目前,该合作正在开发和测试一种无人机操作概念,允许无人机操作员在几个小时内响应检查请求,并在北海启用常规BVLOS。该项目有待与利益相关者进行深入协商,旨在与现有用户一起在受控空域建立安全可靠的无人机操作。

企业间就油气井数据平台展开合作

油气投资组合管理的软件即服务平台公司Lower48 Analytics最近宣布了与BLR Digital的合作。通过此次合作,Lower48用户可以通过访问大量的油气井生产和预测数据来简化工作流程。BLR Digital的井口云包含350多万口油气井数据及其相关生产和测试数据信息,通过此次合作,Lower48将集成BLR Digital这一井口数字云;此外,Lower48还整合了BLR Digital的PetroCurveFit,这是一个基于最新信息为每口井预测生产趋势的系统。这意味着,随着新数据的到来,每个月将可以对超过100万口生产井的产量和未来预测进行计算核查,同时通过Lower48公司的地理定位数据库(geolocated database)获取这些数据,以支持该平台进行财务分析。

For English, Please click here (展开/收缩)

Companies collaborate to deliver actionable data insights for the industry

Schlumberger, Chevron and Microsoft announced the industry’s first three-party collaboration to accelerate the creation of petrotechnical and digital technologies, a press release stated. Data are quickly emerging as one of the most valuable assets to any company, yet extracting insights from those data is often difficult as information gets trapped in internal silos. As part of the collaboration, the three companies will work together to build Azure-native applications in the DELFI cognitive E&P environment initially for Chevron, which will enable companies to process, visualize, interpret and ultimately obtain meaningful insights from multiple data sources. DELFI is a secure, scalable and open cloud-based environment providing E&P software technology across exploration, development, production and midstream. Chevron and Schlumberger will combine their expertise and resources to accelerate the deployment of DELFI solutions in Azure, with support and guidance from Microsoft. The parties will ensure the software developments meet the latest standards in terms of security, performance and release management, and are compatible with the Open Subsurface Data Universe Data Platform. The collaboration will be completed in three phases starting with the deployment of the Petrotechnical Suite in the DELFI environment, followed by the development of cloud-native applications on Azure, and then the co-innovation of a suite of cognitive computing native capabilities across the E&P value chain tailored to Chevron’s objectives. slb.com, chevron.com, microsoft.com

AI application identifies production downtime and process risks

Baker Hughes and C3.ai have released BHC3 Reliability, the first artificial intelligence (AI) software application developed by the BakerHughesC3.ai joint venture, a press release stated. The software application uses deep learning predictive models, natural language processing and machine vision to continuously aggregate data from plantwide sensor networks, enterprise systems, maintenance notes, and piping and instrumentation schematics. Using historical and real-time data from entire systems, the BHC3 Reliability machine learning models identify anomalous conditions that lead to equipment failure and process upsets. Application alerts enable proactive action by operators to reduce downtime and lost revenue. Applicable to operations across all sectors of the energy value chain, BHC3 Reliability’s system- of-systems approach scales to any number of assets and processes across offshore and onshore platforms, compressor stations, refineries and petrochemical plants, reducing downtime and increasing productivity. The AI-enabled BHC3 Reliability application, powered by the BHC3 AI Suite, draws on Baker Hughes’ domain expertise by augmenting application alerts with failure prevention recommendations and prescriptive actions. bakerhughesc3.ai

New ocean-bottom node offers accurate seismic imaging

CGG’s equipment business Sercel has released its GPR, a new ocean-bottom node, jointly developed in partnership with BGP, according to a press release. GPR leverages Sercel’s QuietSeis broadband digital sensor technology to collect data for seismic imaging, which is more accurate compared to the data compiled by conventional sensors. The launch of GPR coincides with the continuing growth and maturity of the global node market and further strengthens CGG’s portfolio of products and services that are designed to reduce the risks and increase the success of its clients’ reservoir exploration and development efforts. The new node has successfully completed sea trials, and BGP’s input from the field has ensured GPR’s performance is tailored to meet industry requirements. It has a compact design and benefits from the fidelity and ultraquiet performance of QuietSeis as well as flexible deployment options. cgg.com, sercel.com, bgp.com.cn

Structural monitoring for offshore construction, inspection and repair

Ashtead Technology’s integrated Deflection Monitoring System (DMS) monitors, calculates, displays and logs structure deflection, heading, pitch, roll, depth, suction and differential pressures in real time, according to the company. Live streaming of data is vital to detect potential issues without delay, reducing the risk of structural damage. The DMS system has been used for monitoring the installation of suction-can based structures such as manifolds, templates and pipeline end terminations. In a recent subsea installation project for Ocean Installer AS, the DMS was configured for autonomous independent operation, communicating data to installation ROVs. Ashtead utilized measurement sensors and positioning tools along with techniques to enhance the accuracy of the data collected, ensuring maximum performance of the system. Data analysis and installation reports for the installation of eight structures were compiled within 24 hours of each installation. The project took place over a 25-day period and was completed well ahead of schedule, resulting in significant cost efficiencies. ashtead-technology.com

New separator eliminates hazardous material during drilling and completions

CP Energy Services’ Sand Commander is a four-way separator used during the drillout of the well completion process to separate all hazardous material, removing 99% of harmful gases and 95% of the sand, according to the company. Sand Commander is designed for ecofriendly completions, cost-effective drillouts, flowback optimization and enhanced safety. The separator is equipped with an improved vertical gas buster where gas is vented out through the top. Return fluids are churned up to enhance gas removal efficiency while keeping sand from clogging up in the bottom. Its multihopper design calms the flow of fluids, helping the sand settle as it goes over the baffles. Water from its fourth compartment can be reused on location for drillout applications. cpenergy.com

Initiative aims to overcome drone inspection challenges

Flylogix Ltd. has launched a North Sea drone initiative in collaboration with Total SA, NATS and the Oil & Gas Technology Centre, as stated in a press release. The project aims to overcome the challenges associated with drone inspection activities in the North Sea and allow commercial operators of unmanned aerial vehicles (UAVs) easier access to U.K.-controlled airspace for beyond visual line of sight (BVLOS) operations. The collaboration is developing and testing a concept for drone operations that will allow UAV operators to react within hours of an inspection request and enable routine BVLOS in the North Sea. The project involves extensive consultation with stakeholders and aims to establish safe and reliable drone operations alongside existing users in controlled airspace. flylogix.co.uk, total.com, theogtc.com, nats.aero/drones-overview

Companies collaborate on well data platform

Lower48 Analytics, a software-as-a-service platform for oil and gas portfolio management, recently announced its collaboration with BLR Digital, which allows Lower48 subscribers to streamline their workflow with access to extensive oil and gas well production and forecast data. Lower48 integrated BLR Digital’s Well Cloud that contains information on more than 3.5 million oil and gas wells and related production and test data. Lower48 also integrated BLR Digital’s PetroCurveFit, which is a system designed to project production trends for each producing well based on the most current information. This means that well production and future forecasts are calculated for more than 1 million producing wells each month as new data come in and are made available in Lower48’s geolocated database to support the platform’s financial analytics. lower48.com, blrdigital.com

未经允许,不得转载本站任何文章:

石油圈

石油圈