New software offers end-to-end asset inspection

Oceaneering International Inc. has released the Inform Inspect digital asset inspection system, which aims to streamline nondestructive testing and inspection management, according to a press release. The tablet-based technology equips technicians, supervisors and managers with the ability to deliver end-to-end inspection from planning to review, with standardized data captured into a cloud-based system. Information is instantly available for analysis, enabling more effective planning and optimization of personnel time on site. Hardware is rated for onshore and offshore applications and is certified for use in hazardous areas. Field trials have demonstrated conservative productivity gains of up to 30% in end-to-end inspection times, and the speed and scope of the technology provide major safety benefits, ultimately enabling personnel to spend less time on site in hazardous environments. The software also can be integrated with integrity management systems and a computerized maintenance management system to increase efficiencies and provide a holistic approach to inspection and integrity management.

Produced water technology provides water and solids management solution

Exterran Corp. has released its new Separon produced water technology suite, according to a press release. The suite of integrated technologies includes desanders, deoilers, multiphase hydrocyclones and microbubble flotation technology for oil and solids removal. It offers onshore and offshore operators a ready-to-use, turnkey package of solutions to treat up to 750,000 bbl/d of produced water. The Separon product portfolio includes a solids removal and transport system, which enables operators to remove and transport solids from production fluids. This cost effective solution mitigates multiple issues downstream including instrument failure, erosion, corrosion and pump damage, all of which reduce vessel tank maintenance.

New wireless condition monitoring system designed to increase productivity

Sulzer has released the Sulzer Sense wireless Internet of Things condition monitoring system, which includes wireless sensors that can be attached to a pump, agitator, motor or any rotating equipment, according to a press release. The sensors measure temperature and vibration and send the data to the cloud, which allows the operating status of the equipment to be remotely monitored 24/7. The Sulzer Sense devices are batterypowered and they operate in a wireless mesh network, making them easy and cost-efficient to deploy and operate. The condition monitoring feature identifies changes in condition parameters and indicates potential faults at an early stage. The Sulzer Sense monitoring device can detect possible imbalance, misalignment, looseness and bearing wear. This supports predictive maintenance and helps to avoid sudden pump failure and eventual downtime. The Sense data are sent to the cloud and can be remotely monitored using Sulzer’s online service.

Companies form international riserless well intervention alliance

COOEC Offshore has formed an alliance with Expro that allows both companies to expand their capabilities and resources, a press release stated. COOEC Offshore is a large offshore engineering contractor servicing the full life cycle of offshore from field development through field decommissioning. The venture into deepwater riserless well intervention (RWI) will further strengthen the depth of service offering to the industry. Expro has recently entered the riser-based intervention market with the Intervention Riser System. As part of this alliance, the RWI system provides a field-proven, established and reliable wire through-water integrated solution for carrying out cost effective intervention and/or abandonment operations on all types of subsea wells. Under the alliance, COOEC Offshore and Expro will deliver this new system to market in 2020, tested and ready for service. The system will be deployed off the new HYSY287 DP3 construction vessel with a dedicated handling and deployment system to facilitate slick and efficient well construction, well intervention and well plug and abandonment activities. Furthermore, with Expro’s recent acquisition of Quality Intervention, the propriety coil hose technology for open water will be a key exclusive capability onboard the vessel. The alliance ensures minimal interfaces, integrated management teams and the majority of the services being delivered in-house.

AI-enabled safety technology for offshore drilling

Seadrill Ltd. has released Vision IQ for offshore drilling rigs, an artificial intelligence (AI) enabled safety technology, which monitors and provides advanced warning of potential risks in the red zone. Vision IQ combines AI, laser imaging, detection and ranging (LiDAR) and advanced edge computing technology to ensure safer and more efficient operations in the red zone for all Seadrill’s offshore rigs and drillships. Comparable to the use in autonomous vehicles, LiDAR technology surrounds the red zone of the rig to create a dynamically monitored environment, while Vision IQ’s AI technology allows real-time monitoring of the red zone using 3-D visualizations. This holistic view enables users to pinpoint the exact position of crew members on the rig floor in relation to moving heavy equipment and provide advanced warning of potential hazards, thereby limiting the scope for human error. Vision IQ is designed for offshore drilling and can be integrated into the rig’s anti-collision system, creating a more unified approach to safety.

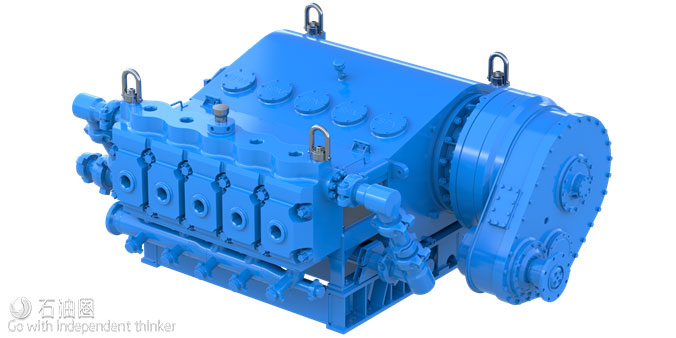

New frac pump for electric and gas turbinedriven applications

Weir Oil & Gas has released its new SPM Quintuplex Extended Max (QEM) 5000 E-Frac Pump, which is a continuous-duty 5,000-hp pump designed for electric or gas turbine-driven applications, according to a news release. The SPM QEM 5000 E-Frac Pump’s compatibility with nonstandard drivers, including electric and natural gas turbines, gives operators the flexibility of tapping into the electrical grid, remote power generation or a natural gas turbine generator, which reduces diesel fuel spend, emissions, overall assets on location and maintenance intervals. The SPM QEM 5000 E-Frac Pump achieves its horsepower with enhanced structural rigidity through an engineered skid and segmented frame plates that significantly extend component life. It also features a dual pressure lubrication system designed to optimize delivery and distribution of clean lubricant to provide extended life and reduced nonproductive time.

Automating the oil field with blockchain

Data Gumbo Corp., a technology company that has developed a blockchain-as-a-service platform to streamline smart contracts for oil and gas, announced that Antelope Water Management has adopted Data Gumbo’s GumboNet blockchain network, a press release stated. This is the industry’s first use of a blockchain platform for total water management services in U.S. shale plays, according to the company. Antelope will tap the power of GumboNet to provide customers and vendors across its water infrastructure, treatment, sourcing and disposal services with real-time data transparency, and automation of contract executions and payments. Antelope’s customers will also benefit from self-executing contracts on a secure blockchain platform catering to complex, 24 hour operations without the need for manual oversight. datagumbo.com, antelopewater.com

Robot removes heat exchanger fouling

Tube Tech International Ltd. has released a cleaning robot designed to eradicate more than 90% of heat exchanger fouling, according to a press release. The new robot is capable of recording videos and images of blockages, concerns and the cleaning, while automatically adjusting to warped tubes. The robot can be programmed with information supplied by the customer, creating a visual representation of the bundle for technicians to utilize before gaining access to the site. This information is used to select the best cleaning process, which can be preprogrammed into the robot. The robot is also designed to bring assets back to original design thermal efficiency regardless of the level of fouling, reducing CO2 emissions.

Subsea capping stacks for enhanced capabilities and response

Wild Well Control Inc., a Superior Energy Services company, announced a new contract with Fugro for the provision of BOP intervention skids and test units for inclusion in its Subsea Response Kit. As part of the WellCONTAINED subsea capping stack program, Fugro’s new 450/150 Mark 3 BOP intervention skids are an advancement in both pumping capability and water depth rating and will replace the existing equipment in inventory, a press release stated. The latest generation of Fugro’s BOP technology offers full skid testing without the requirement of an ROV, the ability to interface to most work class ROV systems, and a bespoke designed self contained storage and maintenance transport container. Deployments of the skid system to date have included full functional testing on a Fugro ROV at 3,800 m water depth, and the BOP system is depth rated to 4,000 m. wildwell.com

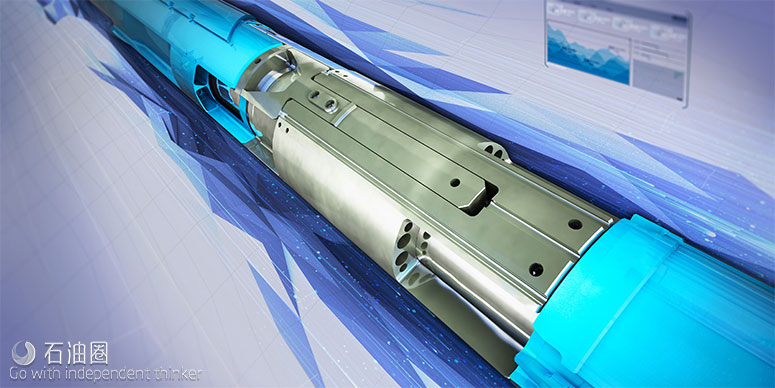

Wireless conveyor for better access to wells

Well Conveyor AS has received a $1.8 million equity investment from Chevron Technology Ventures, ProVenture and Investinor, which will be used in supporting the qualification and commercialization phases for the company’s Slim Battery-powered Conveyor, a press release stated. The Conveyor will be a small diameter downhole tractor offering access to the increasing number of slim, horizontal and highly deviated wells, which are not serviceable with wireline type conveyance. The Conveyor has been optimized for running on batteries, with an electromechanical design, allowing for extended tractoring distances of more than 15,000 ft. Not being dependent on power and communication from the surface allows operators greater flexibility and lower-priced conveyance alternatives. The Conveyor has been designed for simplified operations and reduced maintenance, enabling the service to be provided by the regular wireline/conveyance providers. This translates into less interfacing and manpower being needed for operations. wellconveyor.com

E-course teaches machine learning and seismic interpretation

Geophysical Insights is offering a new comprehensive online learning course on machine learning and seismic interpretation called Machine Learning Essentials for Seismic Interpretation. The information presented will benefit students, new graduates and professionals seeking to broaden their skills, according to a press release. The course may be taken for certification or information purposes. Dr. Tom Smith, founder and CEO of Geophysical Insights, conducts a comprehensive survey of machine learning technology and its applications in this 24-part series. The course is designed for geoscientists, engineers and data analysts at all experience levels, from data analysts who want to better understand applications of machine learning and deep learning to geoscience, to senior geophysicists with deep experience in the field. The major topics covered include operation, foundation, practice and prediction. geoinsights.com/courses

Gas regulator valve to increase reliability

Oxford Flow has released the IM gas regulator valve to increase reliability and reduce costs for operators, according to a press release. The valve is designed to eliminate the diaphragm, stem and external mechanical actuator. With only one moving part, the design minimizes potential leaks and the risk of fugitive emissions, maximizing efficiency and reducing maintenance costs. The valve was released following a successful trial with SGN, where the valve was installed and commissioned with ease, regulating gas pressure smoothly with rapid changing demand profiles within an accuracy class of 1.5%. This accuracy helps operators in achieving faster network stability on commissioning, even where flow rates vary significantly. oxford-flow.com

Analytics platform for industrial control systems security

Cynash Inc. has released the Cynalytic analytics appliance for serial communications-based industrial control systems (ICS) and SCADA control networks, a press release stated. Cynalytic consists of a rack-mount hardware appliance, along with all the application software needed to set up, manage and analyze data, and it includes a suite of data visualization and dashboard tools to help users monitor and make sense of historically unmonitored and unprotected serial communications. Its device and data management capabilities include remote configuration and management of sensors, encryption and authentication of monitored data, serial traffic alert monitoring and deep packet inspection of ICS protocol data, industrial system health monitoring, and asset and cluster management. cynash.com

Hands-free, wearable connected technology helps improve compliance and productivity

Honeywell’s Intelligent Wearables, a hands-free, wearable connected technology, was designed to improve productivity and compliance with process procedures, capture the expertise of experienced workers and provide critical insights and information effectively to trainees and support workers in the field, according to the company. The technology tracks specific key performance indicators and integrates hardware, software and services, and a full Wi-Fi infrastructure to support use of the technology across a plant. The wearable technology also will accelerate training and ensure safety for field operators. Intelligent Wearables provides field workers with live, real time access to experts in the central control room or elsewhere for troubleshooting, support and advice; enables users to view videos demonstrating key tasks; and provides step-by-step instructions for common and complex tasks. By connecting field workers with remote advice, Honeywell Intelligent Wearables also reduce the need for site visits from experts, empower workers to continue learning, become their best and effectively share their knowledge with peers. honeywell.com

Concept for live asset risk assessment using digital twins

DNV GL has proposed the Probabilistic Digital Twin (PDT) to close the gap between digital twins, which are used increasingly by operators to manage the performance of their assets, and risk analysis still largely conducted manually before assets enter service, a press release stated. The PDT is designed to bring risk analysis into live use. Their creation would add a layer of probabilistic risk modeling to existing digital twins, capturing uncertainty, the effect of new knowledge and actual conditions on operational performance and safety. By providing a more up-to date and asset-specific risk picture, a PDT allows operators to adjust operations or take preventive actions to maintain an acceptable risk level at all times. This will enhance safety and reduce expensive downtime, the company said. The PDT concept, unveiled at Offshore Europe 2019, allows DNV GL and its clients to take advantage of all the information such twins contain to improve risk assessments. The PDT is not an alternative, but an evolution of the digital twin—expanding it into the risk analysis space. It is a new way of delivering risk analysis, continuously and in a digital format, adding more value in day-to-day decision-making. dnvgl.com

New lifting equipment delivers enhanced features

Modulift has developed two new equipment products: the Modulift Adjustable Modular Lifting Beam and the Modulift Trunnion Drop Link, a press release stated. The beam offers multiple pad eyes, so the beam can adapt to lift various weights and sizes. It can be used both as a lifting beam and a semi-spreader beam. The modular system reduces handling requirements and transport costs. Modulift’s Trunnion Drop Link is an alternative trunnion option that can be easily and quickly attached to a sling. It requires only one top shackle, thus enabling safer and quicker sling attachment, saving time and money. modulift.com

System allows operators to realize full value of fiber-optic technology

Baker Hughes, a GE company (BHGE), announced the successful deployment of its SureCONNECT downhole intelligent wet-mate system, which enables real-time production monitoring and control of the completion system across the entire wellbore in multitrip completions, a press release stated. This system allows operators to make datadriven decisions to optimize reservoir performance and proactively mitigate risks. BHGE and BP deployed the SureCONNECT system in the Clair Ridge development, marking the world’s first multitrip completion installation with fullbore fiber-optic capability. This is a milestone in BP’s plan to improve surveillance data and well-performance functionality, with the goal of ultimately introducing fiber optics in subsea wells. The operations resulted in successfully mating six optical fibers—each the size of a human hair—between the upper and lower completions, more than a mile below the earth’s surface. The data gathered will be used in parallel with conventional well surveillance data to provide a better understanding of fracture performance in real time.

High-definition dual-imaging-while-drilling service for oil-based mud

Schlumberger introduced the TerraSphere high-definition dual-imaging-while-drilling service at SPE Offshore Europe Conference and Exhibition. The new service provides the industry’s first application of a LWD dual-physics imager for oil-based mud for drilling oil and gas wells, a press release stated. It incorporates electromagnetic and ultrasonic measurements that enable multiple high-resolution borehole images in nonconductive mud. This reveals enhanced details for geological, petrophysical and geomechanical interpretation to uncover subtle variations in the subsurface caused by stratigraphic or structural properties that impact wellbore stability. The real-time transmission of images with these enhanced details enables drillers to make better informed decisions during the near-wellbore stress interpretation process. More than 30 field trials were conducted with the TerraSphere service in the Gulf of Mexico, Middle East, North Africa, North Sea and U.S. land. These trials included successful imaging for structural and stratigraphic analysis, revealing breakout fractures that enabled drillers to avoid mud loss. The new service acquired additional and higher definition data, reducing subsequent operational time and improving net-to-gross ratio in the pay zone. slb.com

Model and optimize production in new and established reservoirs

Emerson has announced its entire E&P software suite is available on the cloud, enabling oil and gas companies to securely take advantage of digital technologies to better model and optimize production in new and established reservoirs. Emerson now delivers seismic processing and imaging, data interpretation, subsurface modeling, formation evaluation, reservoir engineering, production optimization and other services with faster, more powerful computing power to connect critical subsurface intelligence with surface operations. The enormous growth in the volume and complexity of petrotechnical data, combined with the need to reduce costs and enhance E&P productivity, poses a growing challenge for today’s CIOs. Emerson addresses these challenges by utilizing cloud computational horsepower while leveraging proven and reliable machine learning algorithms and other technologies to provide more flexible, scalable and collaborative work processes, helping operators increase efficiencies and achieve top performance.

Platform provides real-time monitoring and control

The Restrata Platform provides real-time monitoring and control of people, environments, assets and reputation, ensuring safer operational management and immediate response times across the energy and industrial sector, according to the company. Cloud-born and mobile-ready, the software-as-a-service platform provides a global view of operations, anytime, anywhere, regardless of the complexity of the organization. Enabling faster, more informed decisions across the organization, from the headquarters through to the control center and site, the Restrata Platform ensures that there is no information gap both locally and globally, providing a unified operating picture. Ultimately, this saves lives and enhances operations. It was designed to manage thousands of sites and millions of people across the globe, providing global firms with 100% visibility and control. The Restrata Platform focuses on minimizing the time from any incident to response and maximizing the information available to decide, helping organizations manage the impact.

Asset management tool could save companies millions in maintenance

Asset integrity management firm IMRANDD is set to launch Advanced Inspection Data Analytics (AIDA), a tool that has the potential to save companies upward of 20% per year in inspection costs per asset and several million dollars from unplanned outages, a press release stated. On a typical mature North Sea installation, hundreds of thousands of wall thickness readings will have been gathered at a cost of millions of pounds to the operator, and distinguishing the “good” from the “bad” data—and how to interpret and apply it—is crucial to operating an asset safely, efficiently and profitably. Weeding out the bad data has previously been a manual task of such magnitude it has been seen as impossible to achieve and has led to potentially valuable data being ignored or dismissed. However, the AIDA software can extract, analyze, cleanse and improve the accuracy of gathered wall thickness data of any age and in any format. With proven capability to analyze the same quantity of data in 30 days that would take two years of engineering work using current methods, AIDA processes the reams of legacy data attached to mature North Sea assets to give reliable, trendable and actionable information.

Field service technicians can easily navigate multiasset environments

Fieldbit has released the addition of real-time data visualization (spatial computing) to its multisource knowledge platform, according to a company press release. Spatial computing empowers field service technicians and operators to more easily navigate in a crowded, multiasset environment and to maintain, operate and resolve issues more quickly and effectively. Technicians and operators servicing oil rigs, refineries and other process plants can now easily locate specific devices or components via color-coded status alerts, operational instructions, data and Internet of Things (IoT) information on their mobile devices. Using smart glasses, tablets or smartphones, technicians, operators and even offsite managers can access real-time data and IoT information about machines, even when they are out of view and located behind or inside other equipment. Spatial computing adds a new layer to the Fieldbit enterprise augmented reality platform and strengthens Fieldbit’s ability to provide industrial asset manufacturers and asset owners with additional tools to overcome the challenges facing field service technicians as they service expensive, complex equipment.

石油圈

石油圈