在2016年的OTC大会上,斯伦贝谢正式推出了MaxPull高拉力井下电缆工具,该系统可以在深达40000 ft (12192 m)甚至更深的井中上提重量为18000 lbf 至30000 lbf的工具。

斯伦贝谢主管电缆的负责人Hinda Gharbi说:“这是目前行业内能提供最高拉力的作业电缆,有了这种电缆传输工具,即使面对复杂的作业情况,现场操作人员在进行电缆作业时也可以省去钻杆的使用,节约时间的同时还能提高直井作业效率并将粘卡风险最小化。除此之外,由于没有使用常规的钻杆作业,还可以降低现场作业的风险。”

攻克难题 行业最高规格的作业电缆

MaxPull在使用中提拉上限可以达到30000-lbf,该公司称MaxPull比之前系统的提拉能力提高了43%。通过与电缆爬行器联合使用,就能够进一步提升电缆进入复杂井眼轨迹的能力,并最小化测井次数。

目前,该系统的现场测试已经结束,测试地点包括了中东、欧洲、亚洲、非洲和美洲的多个油田,几乎覆盖了各种井况,实际应用效果非常好。

在过去的十年中,随着钻井技术不断成熟,深水、超深水、非常规油气田的开发和大位移井的数量显著增加,井况和完井过程也变得越来越发杂。在这些复杂井况下获得足够有效的油藏数据无疑是非常重要的,然而,复杂的井下条件也增加了油藏数据获得的难度。

为应对这些挑战并更有效的控制风险,MaxPull讲多种专门为降低风险而设计的各种组件与TuffLINE*平衡扭矩复合电缆整合,共同下入井中工作,TuffLINE 30000电缆就是一种在工具整合中具有代表性的平衡扭矩复合电缆。由此就产生了世界上第一个拉力可达30,000-lbf的电缆传输工具,达到了前所未有的安全性、可靠性和效率,还可以到达之前的电缆无法下入的井眼和环境中工作。

将MaxPull系统的能力和UltraTRAC*全能型电缆爬行器相结合还能进一步提高推拉能力,能够为所有的井眼环境提供完整的传输解决方案,具有优越的性能:

- 在墨西哥湾成功完成了深度超过36000ft 的测井作业

- 在北美非常规作业的水平井中,成功完成作业

- 在深水油藏中有效地降低工具粘卡的风险

- 摆脱了复杂井况下对传统钻杆传输的依赖,节约时间和耗费

- 在偏远地区的作业中可节约对常规的高强度电缆进行维护运输的费用

应用

MaxPull能够根据客户特定的井况和测井计划量身定制解决方案,确保电缆数据采集最有效、风险最低。

- 深水和超深水井

- 深度超过40000ft的井

- 陆地和海上的斜井、大位移井和水平井

- 非常规井、不规则轨迹的井眼

- 松散地层中的大位移井

技术优势

- 通过工程设计消除了传统电缆数据采集的限制,MaxPull传输系统能最大程度的减少钻机闲置时间:

- 显著降低工具粘卡风险,节约钻机时间

- 提高整套系统的提拉能力

- 可以与双向爬行器共用

- 井内电缆可灵活转动,提高工作效率

- 减少工具组合的下入次数,测井速度更快

- 在任何不规则形态的井眼中都能摆脱对于钻杆传输测井的依赖

- 在任何井眼环境中都能获得有效的高分辨率油藏数据,为制定决策提供更多信息

- 在整个作业过程中,无须将电缆带回岸上进行日常维护,减少了物流成本和时间。

- 消除了在传统电缆作业中出现的深度准确性问题

- 通过提高电缆对抗重力影响的能力,扩大电缆入井范围,消除对试验井进行数据采集的几何形态限制

- 能够下入套管井进行先进的数据采集,避免信息缺口

- 无须等待电缆干燥,节省大量的深水钻机时间

MaxPull 30000系统

不管是在陆上还是海上环境,对于所有的井配置,MaxPull系统都可以作为标准的传输系统下入井内,也可以为了达到最佳的电缆传输性能而采用定制的模式。

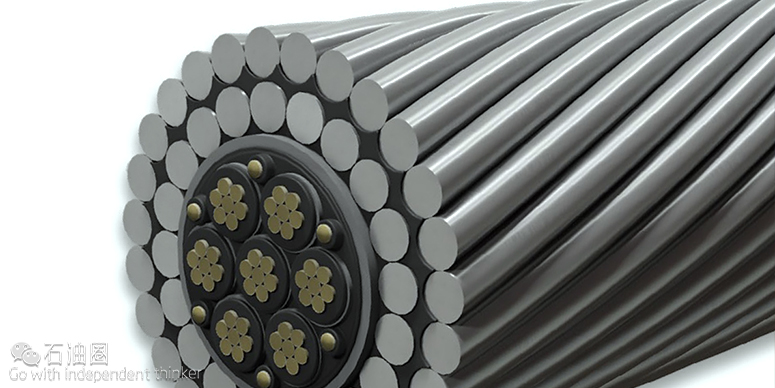

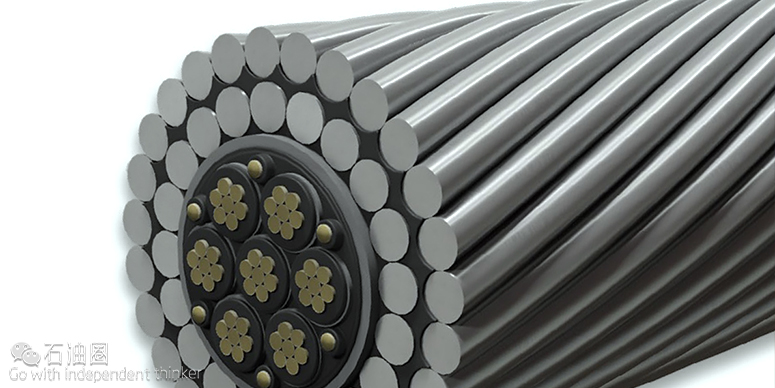

TuffLINE 30000平衡扭矩复合电缆是行业内强度最高的井下作业电缆工具,与TuffLINE 18000 和TuffLINE 26000电缆相同,TuffLINE 30000电缆采用了聚合物锁紧的铠装层突破技术,摆脱了现有铠装电缆的技术限制。该电缆的固有扭矩可以通过增加内部铠装线股的强度来实现,聚合物对铠装层的有效包覆能够阻止铠装层的扭矩累积,防止出现部分区域受力过大的现象出现。TuffLINE 30000电缆两端的抗断强度安全界限比标准的高拉力铠装电缆高出了10000lbf,总体抗断强度也超过了43000lbf。

TuffLINE 30000电缆采用了行业领先的16 AWG(American Wire Gauge美国线规)导体作为芯线,能在深度超过40000ft的井中将长度超过175ft、重达6000lbf的工具组下入井内。工具组合能够减少入井次数,在深水平台,每趟能平均节约12小时甚至更长时间。

来自/Schlumberger 译者/郑斯赫 编辑/Lemon

Schlumberger has launched the MaxPull high-pull wireline conveyance system, which can pull from 18,000 lbf to 30,000 lbf in wells 40,000 ft (12,192 m) deep or more.

Hinda Gharbi, president, Wireline, Schlumberger, said: “With the industry’s highest-pull wireline conveyance system, drillers can expect drill pipe-free wireline operations in any environment with vertical well efficiency and minimum sticking risk. In addition, our customers can mitigate operational risk and save time during comprehensive data acquisition by eliminating the use of conventional drill pipe conveyance.”

The new system can pull up to 30,000-lbf line tension, which the company said is 43% higher than previously possible. It says that the system with wireline tractors further improves well access in complex well trajectories while minimizing the number of logging runs.

The system has been tested in a wide variety of well environments and trajectories in the Middle East, Europe, Asia, West Africa, and North and South America.

As drilling technology matures, the complexity achieved with deepwater, ultradeepwater, unconventional, and extended- reach wells has significantly intensified in the past decade. However, these increasingly deeper and longer wells and the diverse reservoirs they access pose heightened challenges and risk for acquiring the data needed for reservoir characterization.

To meet these challenges and effectively manage risk, the MaxPull* high-pull wireline conveyance system integrates components specifically engineered for risk reduction to deploy wireline tools on TuffLINE* torque- balanced composite cables, including the latest addition to the industry’s strongest and highest-safety cables: TuffLINE 30000 cable. The result is the world’s first 30,000-lbf conveyance system, providing unparalleled safety, reliability, efficiency, and sticking avoidance, even in well trajectories and conditions that were not previously wireline accessible. Augmenting the MaxPull system’s capabilities with the UltraTRAC* all-terrain wireline tractor further increases push and pull capabilities to provide the complete conveyance solution for every possible well environment.

- successfully log wells deeper than 36,000 ft in the Gulf of Mexico

- tractor hundreds of thousands of feet in horizontal wells in North American unconventional plays

- effectively reduce tool sticking risk in emerging deepwater reservoirs

- eliminate conventional reliance on costly and time-consuming drillpipe conveyance for increasingly complex well environments

- save millions of dollars on maintenance transportation trips needed for conventional high-strength cables deployed in challenging remote exploration wells.

Applications

MaxPull conveyance systems are customized for the well environment and the logging program to provide the most efficient and lowest risk wireline acquisition solutions:

- Deepwater and ultradeepwater wells

- up 40,000 ft in depth and requiring

- Land and offshore deviated- development reservoirs

- Land and offshore extended-reach and horizontal wells

- Unconventional wells

- Complex-geometry boreholes

- Extended-reach wells in unconsolidated formations

Benefits

By engineering out the traditional limitations of wireline acquisition, MaxPull conveyance systems provide maximum rig flat-time savings and numerous other benefits:

- Rig flat-time savings from highly reduced tool sticking risk

- High pull capability across the system

- Aided by bidirectional tractor force

- Multiple jarring and cable cycling capabilities

- Rig-time savings through improved well access efficiency

- Rig-time savings with fewer descents of longer, heavier tool combinations and faster logging speeds

- Rig-time savings by elimination of reliance on pipe-conveyed logging in any borehole geometry

- More informed decision making based on cost-effective, complete, comprehensive, and highest possible resolution acquisition of reservoir data in any borehole environment

- Reduction in logistics costs and maintenance turnaround time resulting from no routine cable maintenance trips to shore during the complete well drilling program

- 24 hours of rig-time savings by eliminating the cable seasoning required for all standard high-tension cables

- Elimination of cable depth accuracy issues that occur with conventional cables

- Rig-time savings from reduced seal failures by positioning large wireline formation tester toolstrings with rollers

- Elimination of geometry constraints on pilot wells for data acquisition by extending wireline access beyond gravity descents

- Prevention of information gaps through cased hole access for advanced data acquisition

- Increased safety for high-tension operations with risk mitigation and prevention

- Improved wireline logging efficiency from fewer runs of heavier, longer tool combinations and avoidance of drillpipe conveyance

- Reduced cable maintenance and related transportation logistics

- Greater sticking avoidance through minimized risk of fishing operations and associated rig flat time

- Substantial deepwater rig-time savings with no cable seasoning required

MaxPull 30000 System

The MaxPull system can be deployed as a standard conveyance system or customized for optimal wireline performance delivery in all well configurations across all land and offshore environments.

- 30,000-lbf TuffLINE 30000 composite cable

- OSU-N high-capacity unit

- Capstan 30000 with 30,000-lbf tension-relief capability

- WDR-70 drum with 43,000-ft cable capacity

- Surface-programmable smart wireline jar

- WellSKATE low-friction well-access accessories

- SureLOC electronically controlled cable release device (ERCD) complemented by multiple inline release devices positioned strategically along the toolstring

- UltraTRAC all-terrain wireline tractor for additional 3,000 lbf of push and pull

- MaxWell* integrated field acquisition system for management of power, telemetry, and data

The recently introduced TuffLINE 30000 torque-balanced composite cable is the industry’s highest-strength cable. Like TuffLINE 18000 and TuffLINE 26000 cables, TuffLINE 30000 cable employs the breakthrough technology of polymer-locker armors to overcome the fundamental limitations

of current armored cables. The cable’s inherent torque is balanced by increasing the thickness of the inner armor strands. Polymer encapsulation effectively locks the armors to prevent armor torque accumulation. The result is cable in a permanent ends-fixed condition, which raises the ends-free breaking strength safety margin of TuffLINE 30000 cable to an unprecedented 10,000 lbf above the safe working load (SWL) of standard high-pull armored cable. TuffLINE 30000 cable also has an ends-fixed breaking strength in excess of 43,000 lbf.

TuffLINE 30000 cable incorporates industry- leading 16 AWG gauge conductors to enable reliable conveyance of tool combinations longer than 175 ft and at 6,000 lbf in well depths exceeding 40,000 ft. Combining tools reduces the number of descents in the well, saving an average of 12 hours or more per trip on a deepwater rig.

未经允许,不得转载本站任何文章:

-

- Demons

-

石油圈认证作者

- 毕业于中国石油大学(北京),化学工程与技术硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系Demons(QQ2582825239;微信15810965891)

石油圈

石油圈