Pipeline pressure isolation services

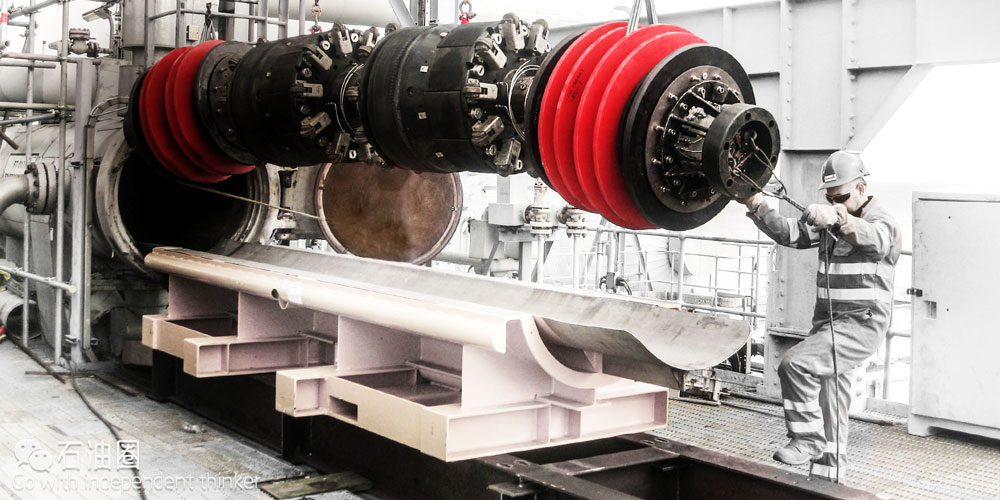

By using TDW’s proprietary tetherless, remote-controlled, bidirectionally piggable SmartPlug tool, any onshore or offshore section of a pipeline can be isolated at (or close to) operating pressure, enabling pipeline repair or maintenance works to be carried out.

This means that any assets connected downstream can continue production while the repair activities proceed. This minimises pipeline downtime and significantly reduces the environmental and economic costs associated with the otherwise inevitable pipeline depressurisation. A special configuration of the SmartPlug tool allows hydrotesting / leak testing of the repaired pipeline to be performed with the same tool.

TDW has performed more than 240 isolation jobs to date with SmartPlug tools of various configurations and sizes (8in to 48in) at isolation pressures ranging typically from 10bar to 250bar. Under certain conditions and with tools of special configurations, this range has been significantly extended from 0bar to 375bar.

The SmartPlug tool is custom-designed for each project with the exact configuration being determined on a case-to-case basis. This inherent capability of the tool to be customised for each job offers extremely flexible solutions.

TDW also offers custom-designed high-friction pigs for pipeline isolation with low delta pressures or for batching / separation tasks with special safety requirements. Typical tasks include separating different pipeline contents and pipeline repair and modification projects. Due to their extremely efficient sealing capabilities, high-friction pigs can also be used for certain cleaning and dewatering applications.

Field-proven with hundreds of offshore projects, SmartPlug® double block and monitor (DBM) technology minimizes platform downtime by enabling operators to isolate pressurized pipelines so equipment maintenance, repairs, and replacements can be done without bleeding down the entire system. By keeping hydrocarbons flowing during scheduled or emergency work, operators maintain productivity and profitability while also avoiding the time, expense, and risks of depressurization and recommissioning.

The SmartPlug system is non-intrusive, tetherless, and remotely controlled. Because both of the two plug modules in the standard configuration can work independently to isolate the full pipeline pressure alone, the tool meets the accepted criteria for a true double block isolation. An optional third plug module is available for post-repair hydrotesting without retrieving the SmartPlug tool from the pipeline. The modules are articulated for improved piggability; in addition, the tool’s bi-directional design enables it to travel in either direction inside the pipeline.

Key features

Bi-directionally piggable.

Onboard control and communications.

Failsafe self-lock via differential pressure; additional built in contingency unsetting system.

Designed to seal against up to 350 bar (5,075 psi) operating pressure.

The integrity of each seal can be validated at all times by monitoring the pressure in the annulus (between the two plug modules), which represents a significant safety advantage.

Eliminates the need for bleed-down of pipeline (decommissioning and recommissioning), which significantly reduces pipeline downtime and lost production days.

No need to remove pipeline contents, flare gas, or dispose of contaminated water.

Pipeline pig-tracking system

The SmartTrack™ two-way communication system enables pipeline operators to improve the safety of pigging operations by providing real-time monitoring of pigs and tools within the pipeline. Not only does the SmartTrack system accurately track, locate, and identify pigs and tools in thick-wall buried or subsea pipes, it was developed for and is still used to track and identify all SmartPlug® isolation tools.

The SmartTrack system has been designed with offshore subsea operations in mind, offering several advantages, such as a long battery life and the ability to track at high pigging speeds and in thick-walled or buried pipelines. Tracking can be performed by a field operator, ROV, diver, subsea antenna or a permanent receiver anywhere along the pipeline.

When running multiple tools / pigs, the SmartTrack system can immediately identify the pig that has passed. High-friction pigs fitted with SmartTrack transponders allow accurate pig-tracking, positioning, identification and continual pressure monitoring, providing an additional degree of safety.

The SmartTrack system is capable of through-wall communication in any pipeline medium and can operate in pipelines up to 50 millimeters (approximately 2 inches) thick. The system also allows for extremely precise pig or tool positioning, with accuracy of +/- 25 millimeters (approximately 1 inch), depending upon the environment.

The SmartTrack system has three basic components: a transponder that emits tracking signals and messages, and receives commands; a transceiver/receiver that picks up, logs, and stores tracking data; and a personal digital assistant (PDA) that records and displays the output signal. The configuration of these components allow for two way communication during operation.

Best used for

detecting and confirming the passage of pigs or tools inside pipelines

confirming the position of a pig or tool to facilitate valve closure

locating stuck pigs or tools

confirming the arrival of a pig or tool at the receiver

transmission of local pressure and temperature readings from sensors attached to tools

Key features

Uniquely tracks up to 16 different pigs passing in one run.

Can be used in conjunction with high-friction pigs for low pressure isolation, offering real-time monitoring of both pressure and position.

Operates onshore or offshore in gas and liquid pipelines.

Transponder settings can be altered during system operation for full user flexibility. Variable signal frequency and strength enables tracking of pigs or tools moving at high speeds and also increases battery life.

Power settings can be controlled for ease of operation in thicker pipe walls, including the pig launcher barrel and valve bodies, where other technologies struggle.

Alarm signal due to changes in pipeline conditions can be transmitted to help safeguard maintenance teams, including dive team

About T.D. Williamson

T.D. Williamson (TDW) is one of the world’s most recognised names in pipeline equipment and services for onshore and offshore applications. TDW’s core business is to provide customers with products and services for effective and efficient pipeline maintenance and construction. TDW offers hot tapping and plugging, pressure isolation, pig-tracking and general repair and maintenance services.

石油圈

石油圈