对于放置有井下封隔器的生产井来说,封隔器的性能直接关系到油井生产的稳定性和效益,当井下设备发生故障或是产量下降需要修井作业时,封隔器的移除又是关系着修井作业是否顺利的重要因素。在许多修井作业中,如果封隔器不能顺利解封、移除,运营商会浪费了大把的时间和成本。

通常情况下,可移除式生产封隔器的使用可以减少操作时的非生产时间(NPT)、费用以及风险。但是当封隔器在高压和高温环境中使用时,可移除式生产封隔器就可能会永久坐封,为封隔器的移除带来巨大的困难。

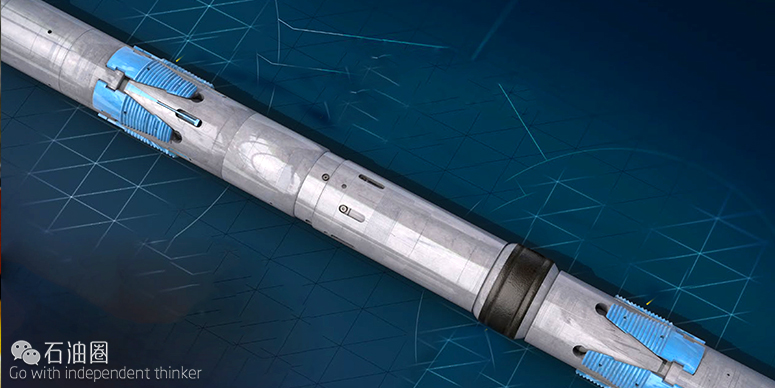

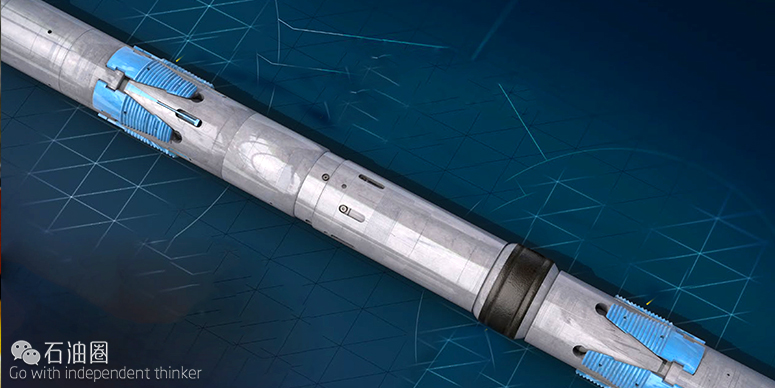

针对此种状况,贝克休斯推出了全新的适用于高温高压环境的可移除式生产封隔器。在井内流体流动时,贝克休斯的高压/高温可取式生产封隔器可以提供油套管之间的可靠密封,同样当井下作业需要解封时可以提供可靠的解封作业,大大减少了作业风险和NPT。

BASTILLE封隔器 专为高温高压设计

在之前的作业中,当井下温度超过177℃(350℉)、压力超过12,500psi(862bar)时,尽管是耐高压/高温的橡胶和卡瓦也可能永久坐封在套管内,造成无法解封、回收的难题。当这种情况发生在深井中时,可能导致至少一天的钻磨和打捞时间,花费高达1亿多美元,此外还增加了质量、安全、环境风险。

事实证明,对传统可取式封隔器进行简单的升级并不能彻底改善其工作性能,无法保证在高压/高温环境中封隔器的移除难易程度。BASTILLE是业内第一个专门针对高压(17,500psi)、高温(204℃)条件设计的可移除式封隔器产品。

在测试时,尽管长时间暴露于温度达到204℃(400℉)、压力等级达到17,500psi(1,207bar)的环境中,它解封时仍可以与套管分离。在高压/高温环境中,BASTILLE可取式生产封隔器仍能够保持可取性能,这就意味着:

- 无需钻磨石油圈原创www.oilsns.com

- 无需打捞

- 无需等待

- 无套管损伤

BASTILLE作业原理石油圈原创www.oilsns.com

当井下作业需要干预时,下入机械式油管割刀到井内置于封隔器下卡瓦下方。它可以将中心管分割成两段的同时封隔器的外部管壁保持原样。当生产油管被拉出井口时,中心管也被取出,这种操作可以释放下卡瓦和胶筒。

随着生产油管持续拉出,上部压力剪切销钉被剪断。封隔器胶筒外壁向内收缩,上部卡瓦与套管壁分离,减小了摩擦力并使得封隔器与套管壁分离。随着生产油管的上升,中心管的肩部捕捞住封隔器的外壁,因此整个封隔器总成随着生产油管被取出。BASTILLE封隔器提高了高压/高温井中可取式生产封隔器的拆卸效率。贝克休斯同时提供应用于标准环境(非高压/高温)中的SCION可取式生产封隔器。

一次下钻坐封时,首先将封隔器下入到预定位置时,通过在位于封隔器下方的短接下入堵头而后加压实现坐封。BASTILLE封隔器可以通过螺纹直接与生产管柱连接,也可以与锚定坐封总成连接,这样拆除生产油管时不必解封封隔器。无论选择何种坐封方式,BASTILLE封隔器都能够提供在高压/高温环境中可靠的气密性能,同时具有在后续修井作业中取出封隔器的灵活性。

永久式生产封隔器移除时往往需要钻磨操作,这会引发作业费用、HSE风险增加以及损坏套管的风险。BASTILLE封隔器具有通过切割释放封隔器的特色,只需要利用化学切割工具或利用与连续油管配置使用的机械式油管割刀即可轻松释放封隔器,使封隔器轻松回收成为可能。

应用石油圈原创www.oilsns.com

- 多级完井

- 深井和超深井作业

- 温度达到400℉、压力达到17,500psi的高压高温环境

特色和优点石油圈原创www.oilsns.com

- ISO 14310 V0评级:保证在恶劣环境中的气密封性能,帮助维持井筒完整性。

- 设计有切割释放模块:固定封隔器于套管中直到中心管被切断,可实现单程解封,坐封时不需移动零部件,增强了可靠性,支持多级完井作业。

来自/Baker Hughes 译者/赵金成 编辑/Lemon

Removable production packers can eliminate non-productive time (NPT), costs and risks during well intervention operations. But they can become permanently set when exposed to high pressures and temperatures. The Baker Hughes BASTILLE HP/HT removable production packer creates a reliable seal between the casing and tubing while the well is flowing and just as reliably disengages when well intervention is needed.

Previously, when downhole temperatures and pressures rise above 177 C (350 F) and 12,500 psi (862 bar), even HP/HT-rated elastomers and slips could permanently set inside the casing wall. When this occurred, the result was at least one day of unplanned milling and fishing time at a cost of $1-plus million in deepwater wells, in addition to increased HSE exposure.

Simply upgrading a conventional removable packer with HP/HT materials is not sufficient to ensure packer removal in HP/HT conditions. The BASTILLE chassis has been engineered specifically to separate from the casing wall when released, even after prolonged expo- sure to temperatures up to 204 C (400 F) and differential pressures as high as 17,500 psi (1,207 bar), an industry first at these ratings.

When intervention is needed, a mechanical pipe cutter is run in hole and aligned below the bottom slips. It makes a cut to sever the inner mandrel while the outer packer wall stays intact. When the production tubing is pulled uphole the mandrel follows. This action releases the bottom slips and relaxes the elastomer. As pulling continues, the upward pressure shears pins that let specially designed segments break free. The packer wall flexes inward, and the upper slips pull free from the casing wall, reducing friction and letting the packer break free from the casing. On its way uphole shoulders on the mandrel catch the outer packer wall, and the entire assembly is retrieved with the production tubing. The BASTILLE packer extends the efficiency of removable production packers to HP/ HT wells. Baker Hughes also offers the SCION removable production packer for use in wells with standard (non-HP/HT) conditions.

One-trip setting is accomplished by pressuring up against a plugging device below the packer after it has been run to depth. The BASTILLE packer can be threaded directly onto the production string, or it can be connected with an anchor seal assembly so the production tubing can be removed without having to release the packer. Either way, it provides a gas-tight, reliable seal in HP/HT conditions while offering the flexibility to remove the packer later as needed for workovers and recompletion operations.

Unlike permanent production packers that require drillout runs—leading to increased costs, HSE risks, and potential for damaged casing—the BASTILLE packer features a cut-to-release design that makes it possible to remove the packer with a chemical cutting tool, or mechanically with the Baker Hughes Mechanical Pipe CutterTM (MPCTM) tool deployed on coiled tubing.

Applications

- Multizone completions

- Deepwater and ultradeepwater wells

- HP/HT environments with temperatures up to 400°F and pressures up to 17,500 psi

Features and Benefits

- Ensures gas-tight sealing in harsh environments

- Helps maintain wellbore integrity

- Cut-to-release modular design

- Locks the packer into the casing until it is cut

- Enables one-trip retrieval

- Requires no body movement while setting, enhancing reliability

- Supports single- and multiple-packer completions

- Reengineered packer construction

- Inner collet relaxes the energy of the packing element when cut to aid retrieval

- Specially designed segments retract to allow the packer wall to contract and free the slips from the casing wall

- Full disengagement enables the packer to move freely in the casing, easing retrieval

The BASTILLE removable production packer stays removable… Even in HP/HT conditions. That means:

- No milling

- No fishing

- No waiting

- No casing damage

未经允许,不得转载本站任何文章:

-

- Demons

-

石油圈认证作者

- 毕业于中国石油大学(北京),化学工程与技术硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系Demons(QQ2582825239;微信15810965891)

石油圈

石油圈