In the current challenging climate of low oil prices, more than ever, the pressure is on operators to reduce the cost of subsea operations. Flowline procurement cost, installation cost and typically expensive and timeconsuming rigid steel spool metrology & installation, drive operators to identify cheaper spoolable flexible pipe solutions.

At the same time, there is a need to reduce operational cost. One of the main contributors to operational cost for flowlines is pipeline integrity management and in particular corrosion management, monitoring, prevention and repair.

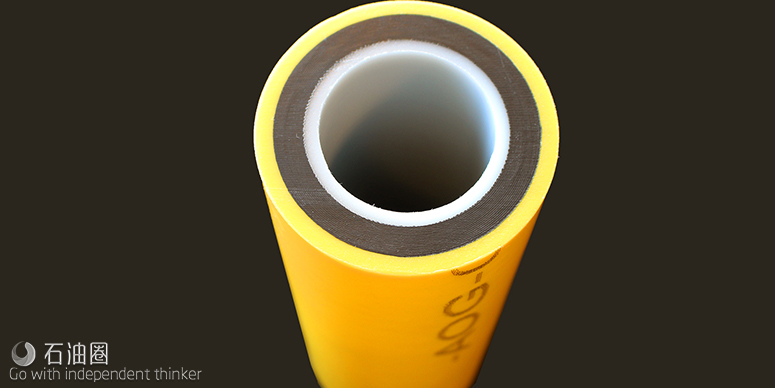

Airborne’s Thermoplastic Composite Pipe (TCP) Flowline is the only product in the market that combines flexibility, ease of installation, and a product which is available in long lengths. TCP has unique low-weight and corrosion resistant properties. It is this combination that makes TCP Flowline the best option for offshore flowline applications, reducing both capital and operating expenditure.

Airborne Oil & Gas has manufactured the world’s first hydrocarbon transport TCP Flowline for Petronas to replace existing rigid steel flowline. Petronas has selected the TCP Flowline to permanently ban pipeline corrosion, the root cause for the replacement of the existing pipelines and to achieve a reduction of the asinstalled cost compared to rigid steel pipeline.

TCP Flowline Installation In comparison with conventional rigid pipe, installation of TCP Flowline has the following advantages: Installation of the TCP Flowline can be carried out with low cost installation vessels. No pipelay barge is required. Instead the TCP Flowline can be laid with a standard offshore support vessel with sufficient deck space for the deployment equipment including the reel No seabed preparation or free span corrections are required, the flexible TCP Flowline will follow the seabed profile No subsea pipeline termination (PLET) or spools are required. The TCP Flowline can be installed without subsea connections Platform tie-in can be completed with the same vessel in one operation No metrology and no divers are required to complete the installation Crossings with existing pipelines are simple thanks to the pipe flexibility

TCP Flowline eliminates corrosion and is the lowest total installed cost solution for greenfield and brownfield applications.

Airborne Oil & Gas designs and manufactures TCP Flowline products for hydrocarbon production, water, gas lift, and chemicals injection. Its non-corrosiveness, light weight, spoolability and ability to terminate in the field make it the best solution for in-field flowlines, tiebacks, single well step-outs, and (quasi) static risers.

The solid pipe structure is impervious to corrosion, resulting in outstanding performance in corrosive environments. It has an inner, fully bonded, smooth bore polymer liner that ensures the best attainable flow properties while still being piggable. The thermal performance of TCP is considerably better than that of steel (reinforced) pipe. Our end-fittings are simple and robust, relying on a well-proven mechanical clamping method. Assembly of the pipe with our end-fittings is straightforward, can be done both onshore and offshore and at any location on the pipe.

Our TCP Flowline is supplied in long spoolable lengths for cost-effective reel lay and lowest as-installed cost. This leads to a radical 30% saving on as-installed cost as shown in the TCP Flowline business case. In addition, the lack of corrosion reduces corrosion-related cost such as pumping of corrosion inhibitors, relating pigging, etc.

Our designs and selection of materials are adapted to the specific requirements of each project, ensuring a fit-for-purpose and highly cost-effective solution for each project. We manufacture TCP Flowline up to 7.5 inch ID, 121 degrees C (250 F) and 10 ksi working pressure.

Storage, Transportation and Installation Reels

Flowlines are supplied on storage, transportation and/or installation reels, allowing deployment with a reel drive system. The reels can be offered on a purchase or rental basis.

Ancillaries & deployment

Costs associated with the prevention of metallic corrosion or replacement of affected subsea flowlines are a serious threat to profitable operation of new and existing assets.

With the intro duction of our non-metallic, fully bonded TCP Flowline, corrosion is no longer an issue. This reduces the operational expenditure dramatically. Our TCP Flowline is manufactured in long, spoolable lengths, reducing installation cost significantly, even compared to carbon steel.

The TCP Flowline offers the following advantages:

- No corrosion

- Flexible and spoolable

- High internal and external pressure ratings

- Smooth bore – fully piggable

- Simple, reliable and field-mountable end fittings

- Low U-value compared with steel pipe

- Continuous lengths of 3,000 to 6,000 metres depending on diameter and pressure rating

- Quick installation by reel lay or surface tow method

- Lowest total installed cost and total cost of ownership

The flowline is developed for offshore use in shallow and deep waters and is designed for oil field conditions with exposure to seawater, sweet and sour hydrocarbon mixtures and oil field chemicals.

To meet pressure and temperature requirements, the TCP Flowline is optimised by using the right materials for the job. This includes glass or carbon fibre reinforcements, and polymers including PE, PA12 and PVDF.

石油圈

石油圈