Connector Subsea Solutions (CSS) has signed an agreement for the acquisition of Hydratight’s MORGRIP Connector business in Walsall, UK.

Over the last six years, CSS and Hydratight have collaborated to deliver challenging subsea pipeline repair projects. The MORGRIP Connector business will become an integral part of CSS’ extensive repair and modification services for subsea and deepwater pipeline repair. The consolidated entity will consist of 60 employees dedicated to pipeline repair products and services.

Pipeline repair connectors are critical components in the repair of oil and gas pipelines. The operator’s requirements for this type of equipment are extremely high as the consequences of failure are dramatic with regards to potential environmental and commercial impacts and even to a region’s overall energy supply. MORGRIP Connectors boast a 100% leak free in-service track record of over 30 years.

Hydratight’s MORGRIP business has a reference list second to none with more than 3,000 connectors delivered to the global oil and gas industry. MORGRIP’s offer a unique, robust, field proven, durable design that meets all of the industry’s strictest qualifications. This makes MORGRIP the primary choice of connector for the repair of critical pipelines and is in use by most of the major operators.

The MORGRIP connector has also proven to be the connector of choice for emergency pipeline repair systems (EPRS) worldwide and through the acquisition, CSS takes a lead position providing emergency pipeline repair for more than 300 high value pipelines.

The acquisition of the MORGRIP business completes CSS’ products and service offering enabling CSS to take a lead role in providing complete subsea and deepwater pipeline repair solutions, delivering it’s services on a sale or rental basis worldwide.

“This has been a strategic move to build a foothold in a market that we believe will grow significantly the next few years. With the MORGRIP Connector and the MORGRIP team onboard we have taken a position to meet client’s requirements for the effective execution of demanding deepwater pipeline repair projects,” said Pål Magne Hisdal, chairman of CSS.

“The strong synergies already in place between the teams have already enabled us to develop unique and effective solutions, this fully integrated business offers ourselves and the market some very exciting opportunities,” added Paul Hughes, MORGRIP business leader.

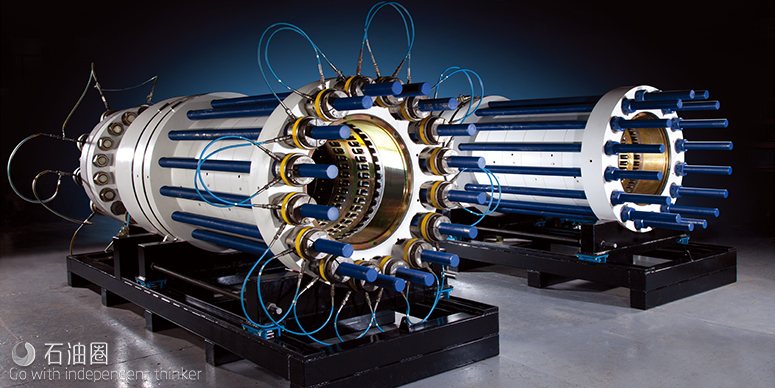

MORGRIP® Connectors are weldless mechanical connectors which provide a high integrity connection for all types of metal pipework, onshore and offshore, topside and subsea. They are designed to be used as a fire-safe weldless replacement for a permanent pipeline repair, blanking redundant lines or for tie‑ins.

Connector Configurations

Flange Adaptor

The Flange Adaptor terminates a bare-pipe with an ASME/ANSI Class flange forming a lightweight, compact and low-cost connection. This configuration is used in flange replacement, pipe re-routing/tie-in, capping pipe that may require later intervention, and spool repair; and applicable topside or subsea.

Coupling

The Coupling joins one bare-end pipe direct to another. The Coupling provides a lightweight, compact and low cost option ideal for use in re-routing/tie-in, and spool repair applications; and can be used topside or subsea.

Pipe Adaptor

The Pipe Adaptor is pre-welded to the bare-end pipe as part of the fabrication process. It is then used to connect to existing pipework without the need for hot work. The Pipe Adaptor provides a flexible engineered solution to overcome specific piping repair requirements and installation demands.

End Cap

The End Cap provides a simple and effective way of capping-off redundant pipe as a permanent repair or on a temporary basis as part of a shutdown or larger repair procedure. The End Cap can also be used as part of a pressure test and can be provided with integrated porting for spool testing.

All formats suit specific applications, whether for use on carbon steel, stainless steel or duplex pipes. Other Connector configurations are available such as Tee Connectors and Reducer Connectors on an engineered projectby-project basis through our dedicated engineering team.

Hydratight’s range of MORGRIP Connectors offer versatile solutions to the problem of bare pipe connections. Their design is adapted to suit applications ranging from high temperature, high pressure hydrocarbon service lines fitted on the topside of offshore platforms, through to the supply of connectors capable of being remotely installed in over 3,280 ft (1,000 m) of water. They provide a connection that is equal in strength to a weld and has DNV and Lloyds Type approvals, stating that the Couplings may be used as a permanent or temporary substitute for welded connections.

石油圈

石油圈