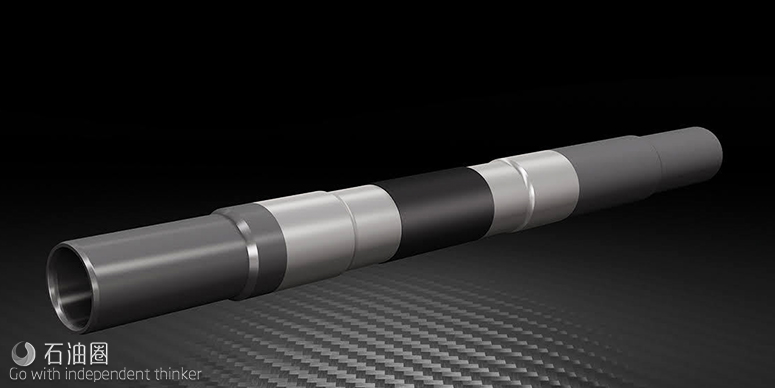

Combining trouble-free precision and economy, the MorphPacker from Nine is the optimal completion solution for your re-stimulation project.

Extend the life of your well completion

If you’re looking to re-stimulate your well, the MorphPacker completion technology from Nine delivers in a big way. Combining precision with cost efficiency, it extends the productive life of conventional and unconventional wells.

A solid alternative to costly expandable liners and unreliable chemical diverter solutions, the MorphPacker instantly isolates and re-fractures stages, reducing capex, personnel requirements, logistical costs, and environmental footprint.

Features

- Super-slim OD and Big Bore ID design matching conventional pipe

- Large ID for increased pumping rates

- Full re-stimulation control

- Minimal loss of ID matching standard liners

- Inert metallic sleeve impervious to wellbore fluids

- Instant on-demand active metal seal

- Easy deployment with conventional equipment

- Simple, robust, reliable design—no moving parts or leak paths

- Flexible configuration; uses standard plug & guns and ball-drop sleeve systems

- Differential pressure ratings up to 10,000 psi

Flexible, easy-to-use, and effective for a wide range of applications

- Run in cased hole; energized with production tubing (or work string)

- Re-stimulation of multi-stage wells

- Isolation of old perforations

- Remedial straddle-patching

How does the MorphPacker enhance productivity?

Put simply, there’s less that can go wrong. The MorphPacker features an active metal seal and a simple design—no moving parts and no leak paths. While other systems feature costly expandable liners and unreliable chemical diverters, our design has an inert metal sleeve impervious to wellbore fluids. Plus, the larger ID allows for greater pumping rates once you’re in place.

Where can I use the MorphPacker?

The MorphPacker can be run in conventional or unconventional cased-hole applications, energized with running tubing or work strings; the re-stimulation of multi-stage wells; the isolation of old perforations; and remedial straddle-patching applications.

How much pressure can the MorphPacker accommodate?

MorphPacker is rated for differential pressure up to 10,000 psi.

How compatible is this system with other configurations?

Very. It matches standard liners with a minimal loss of internal ID. And its flexible configuration accommodates both standard plug-and-gun and ball-drop sleeve systems.

BENEFITS

- Large ID allows for increased pumping rates

- Full re-stimulation control

- Minimal loss of ID matching standard liners

- Inert metallic sleeve impervious to wellbore fluids

- Flexible configuration/uses standard plug & guns and ball drop sleeve systems

- Cost-effective alternative to expensive expandable liners and unreliable chemical diverter solutions

石油圈

石油圈