In unconventional reservoirs, operators are constantly adjusting various stimulation treatment parameters in an effort to improve well performance. Today’s completion designs manipulate stage length, treatment rate, number of clusters, perforations per cluster, and entry hole diameter as an attempt to achieve more fractures per wellbore. The challenge is effectivity stimulating each cluster and achieving these outcomes in a timely and cost effective manner.

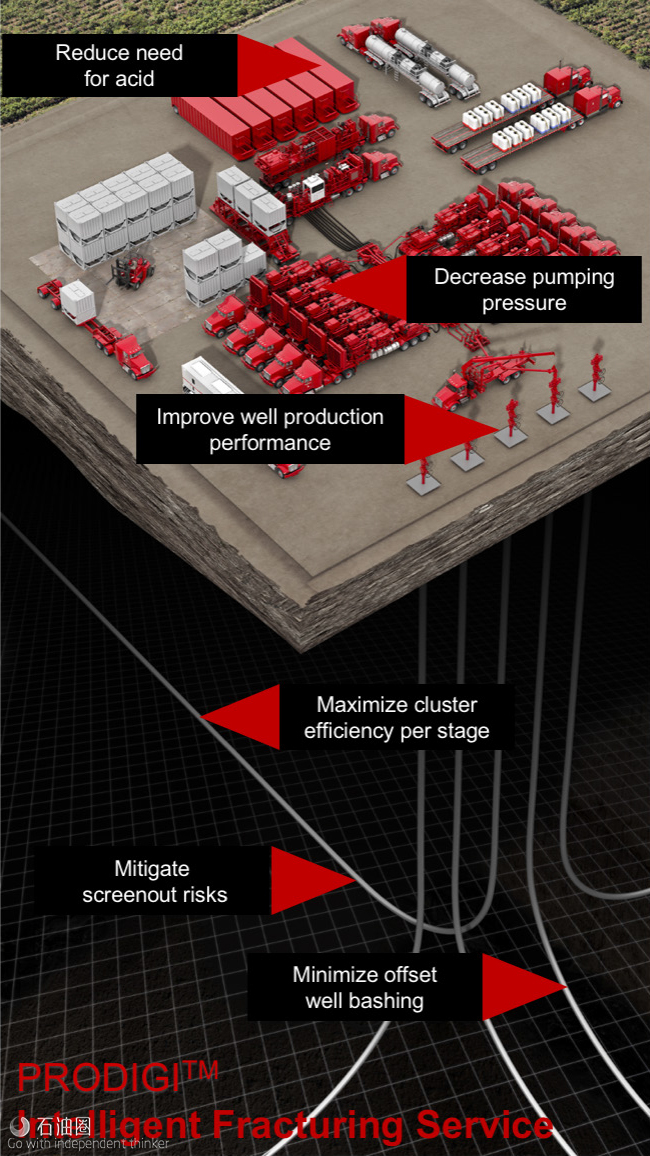

Halliburton’s Prodigi Intelligent Fracturing Service incorporates data from thousands of stages along with real time information to automatically control pumping parameters to deliver uniform fluid distribution. This data rich approach coupled with an advanced control system architecture allows the Prodigi Intelligent Fracturing Service to maximize cluster efficiency and achieve more uniform fluid distribution between clusters on every stage to a degree not possible with manual manipulation.

Wells instrumented with fiber optic sensors have revealed that conventional treatments with manual rate control lead to an uneven flow distribution across the clusters that can vary as much as 14 bpm between individual clusters once full treatment rate has been achieved. Applying Halliburton’s Prodigi Intelligent Fracturing Service mitigates this disproportion of flow across clusters by intelligently breaking down the formation using highly trained algorithms directly controlling job treatment rate. In a recent study flow distribution was shown to vary by 0.1 bpm flow rate across the entire perforation cluster set when Prodigi service was utilized.

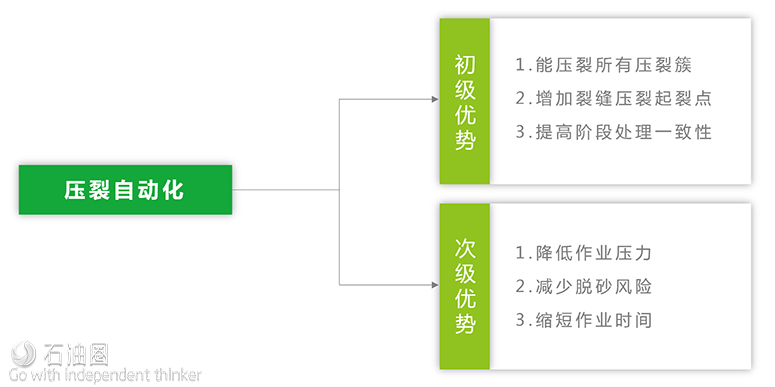

With Prodigi service, your breakdown process can be optimized on every stage of every well maximizing your stimulation spend. By achieving a more uniform distribution of fluid and proppant across clusters, numerous other benefits have been observed in unconventional basins including lower treating pressures, faster stage pumping times, and eliminated screen outs. Further, since the process is automated, each stage is treated consistently to reduce the overall variability of the stimulation execution, stage to stage and well to well.

FEATURES

• Real time treatment rate control for stage to stage consistency

• Deliver maximum cluster efficiency with real time treatment feedback

• Minimize human interaction for stimulation rate control

Case Study

An exploration and production (E&P) company that operates in the Permian Basin approached Halliburton when it was targeting an undeveloped area of the Delaware Basin in Reeves County, Texas. The operator was interested in collaborating with Halliburton to design and execute a stimulation treatment in line with the basin’s operational trends in order to maximize production.

Operating in the Delaware Basin can be particularly challenging. High fracture gradients cause elevated treating pressures and unpredictability during stimulation. Geological and operational inconsistencies lead to understimulated perforation clusters. Designed treatment rates are difficult to reach; jobs are frequently not pumped as designed; and it is difficult, if not impossible, to optimize the treatment for maximum stimulated reservoir volume. These challenges result in an inconsistent execution of the designed stimulation treatment.

To solve these challenges, Halliburton recommended its Prodigi? intelligent fracturing service to provide a consistent approach to formation breakdown. Specifically tuned to formation properties, Prodigi service is able to adapt to downhole conditions by autonomously and intelligently changing the pump rate during the breakdown phase of the treatment in order to deliver more uniform fluid distribution across multi-cluster intervals and to maximize cluster efficiency. To evaluate the effectiveness of the treatment design, the Halliburton team could also provide real-time subsurface monitoring of the fluid and proppant distribution in each cluster by using its StimWatch? stimulation monitoring service.

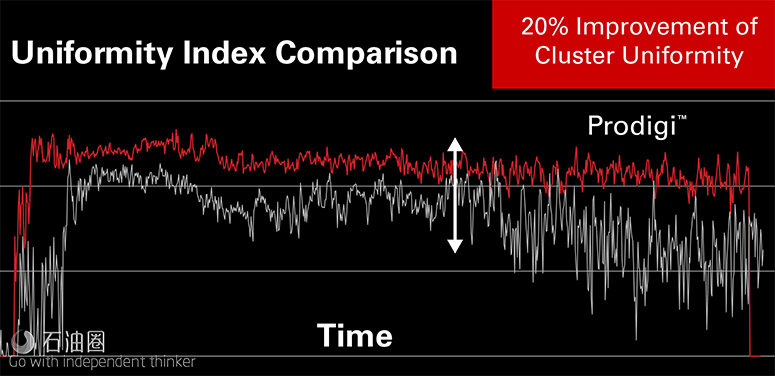

The results from utilizing the Halliburton Prodigi service has been impressive for this E&P company in the Permian Basin. Fiber-optic monitoring measured the Uniformity Index, an evaluation of the flow distribution between clusters, for each and every stage along the wellbore. The implementation of Prodigi service yielded a 20 percent more uniform distribution of fluid and proppant, as observed by the StimWatch stimulation monitoring service and depicted in Figure 1. For comparison, these two stages were pumped in the same horizontal well, both executed with the same perforation design and the same maximum rate of treatment. Not only does the Uniformity Index of the Prodigi stage outperform that of the manual stage, but it maintains a consistent level throughout the entirety of the stage while placing proppant. Enabling a more efficient formation breakdown process, Prodigi service created more fracture initiation points along the wellbore, which will lead to improved well productivity as indicated in SPE-194331-MS.

Prodigi service eliminated human intervention during the breakdown and rate ramping intervals, thus bringing consistency to the process and results, stage to stage and well to well. The former approach to pressure management during stimulation treatments often resulted in unnecessary pressure spikes on the surface – causing delays, pump kickouts, and incorrect diagnoses of downhole conditions. This variability in the overall stimulation treatment has been reduced, resulting in the Permian Basin operator’s ability to better plan future development and completion activities. As a result of improving cluster efficiency during breakdown, the designed treating rate was achieved earlier than when using traditional breakdown methods. In fact, Prodigi service reduced the overall treatment time, on average, by 30 minutes. All of this has translated into better wells.

石油圈

石油圈