A new end-to-end technology suite addresses inefficiencies in large projects.

Ocean-bottom seismic (OBS) acquisition techniques are an effective means of building high-quality seismic datasets, but operational inefficiencies have made scaling OBS difficult for large exploration projects. Challenges exist in source control, in node management, in the number of vessels involved in the operation and in quality assurance/quality control (QA/QC) of the various datasets produced. The scale of the operations, and the interdependencies inherent in each step, create numerous opportunities for delay that can compound with each phase of the survey operation. To address the cascading nature of these inefficiencies and to create the efficiencies of scale required for large projects, a new holistic approach to OBS acquisition is required.

Increasing the value of the data by enabling better geophysics and delivering it to E&P geoscientists more quickly requires that acquisition operations be brought to a new level of performance—the key to this performance is a data-centric approach, where cutting-edge software drives novel, “smart” hardware in a digital transformation of the OBS world.

ION has leveraged best practices and technology envisioned during the firm’s time operating its own seabed acquisition business to develop an end-to-end OBS offering called 4Sea. The objective of the 4Sea technology is to dovetail each step of the acquisition operation, compounding performance benefits at each phase for a more cost- and time-effective result.

Acquisition planning and optimization

Once the initial survey design has been completed and all the geophysical imaging requirements met, the operations planning can begin. As shown in the following project, multiple acquisition scenarios were simulated in ION’s MESA SimSurvey software, constrained by the geophysical objectives, equipment availability and associated costs, allowing the optimal plan to be selected.

• Survey area: 344 sq km (133 sq miles)

• Water depth: 80 m (262 ft)

• Geometry: Parallel shooting, 18,000 nodes (node-on-a-rope operation)

»» Template size: 5,200 m by 5,200 m (17,060 ft by 17,060 ft)

»» Receiver grid: 100 m by 100 m (328 ft by 328 ft)

»» Source: dual source, 25-m (82-ft) shot interval, 50-m (164-ft) line spacing

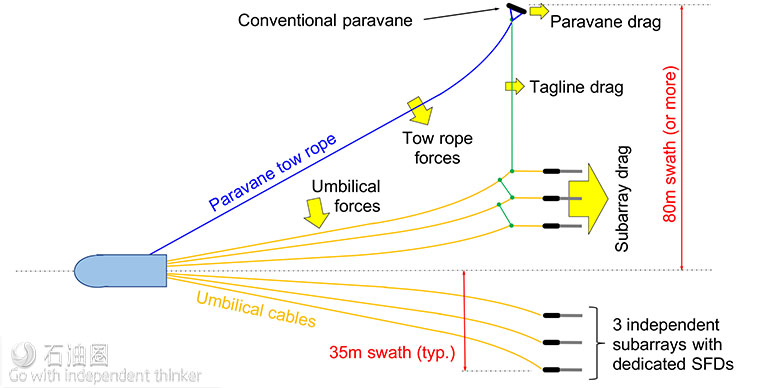

The simulations run focused on the cost and timing impacts of using ION’s SailWing source steering system versus a conventional paravane setup. The results are shown in Table 1.

TABLE 1. A comparison of results when using the SailWing source steering system versus a conventional paravane setup is shown. (Source: ION)

The results showed that using a single SailWing-equipped source vessel reduced the overall survey cost by 15% and required only two additional days to complete.

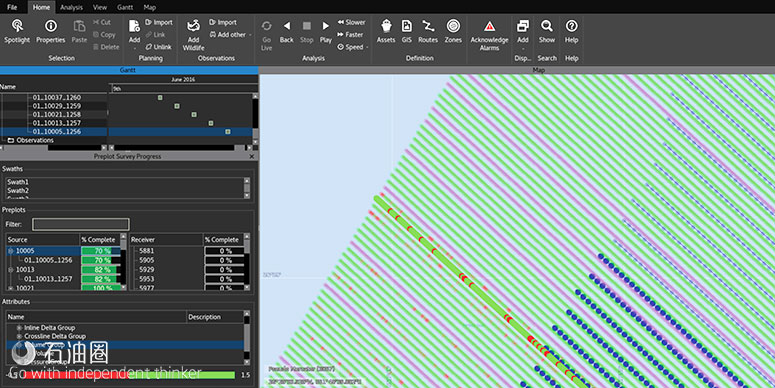

By their very nature, OBS operations increasingly take place in congested offshore environments, where the seismic acquisition is taking place among tanker, supply and diving operations. ION’s Marlin software provides a digital platform that enables multiple stakeholders across the field operations to share and visualize vessel route plans, foresee and avoid conflicts between vessels and fixed installations, optimize schedules safely within a rules-based environment, and measure and improve asset performance. The operational plan from MESA SimSurvey was incorporated into the overall plan within Marlin for final optimization and communication to the other parties active in the field.

Acquisition operations

Automation is the key to safe, efficient operations. Gator, a software package that drives real-time command and control across multiple source and receiver vessels, is the basis for the DataHub, a central data repository for all information and data related to the survey. The DataHub is an efficient, integrated software system providing automated workflows for

everything from preplot information through control of the node attach/detach process, source steering, downloading of the seismic data and automated QA/QC of the results.

The speed of node deployment and retrieval is possibly the largest factor governing the survey duration, and an automated back-deck system accelerates this process, enabling node-handling vessels to operate at higher speeds—deployment and retrieval at up to five knots can markedly reduce total vessel time over the course of a project. Flexibility was central to the design

philosophy behind the system and a key feature is the compatibility with virtually any seabed node, allowing unprecedented operational flexibility.

Being automated, the back-deck system also reduces the crew size requirement, minimizing HSE exposure and risk. Under the control of the DataHub, the backdeck systems can attach nodes to the carrier line at any spacing, enabling and simplifying modern survey design concepts such as random and compressive sensing techniques.

The survey plan also calls for improved source vessel performance, and this is provided by SailWing active source steering. This segmented-foil diverter (SFD) replaces conventional paravane diverters and de-risks the source operation by allowing faster line turns, easier handling and simpler, safer online maintenance of individual gun arrays, less drag and more consistent array stability for better geophysics (e.g., 4-D repeatability). The reduced overall swath width of the in-water equipment also allows for safer, closer passes to existing infrastructure (Figure 1).

FIGURE 1. This illustration provides a plan view of a dual-source configuration, with the starboard side source utilizing a conventional diverter (paravane) with its dedicated tow rope and interconnecting taglines, and the port side source utilizing SFDs; one SFD is dedicated to each of the three subarrays. (Source: ION)

On a project earlier this year, line turn time reductions of 66% were achieved, reflecting those used in the project simulation in Table 1.

Data QA/QC challenge

The current reality of many ocean-bottom node (OBN) operations is one of separated work silos, multiple different pieces of software and data formats, the use of import/export steps and even email to transfer information around the operation. The result is labor intensive, can be error prone and runs the risk of missing information. To add to the challenge, the OBN world is one of increasing data densities and acquisition rates leading to too much data to review using traditional approaches. Use of the centralized DataHub provides a central data repository via an integrated software system and automated workflows—the result is no need for import/export steps, no duplication, no loss of information and, above all, improved efficiencies and data quality.

ION’s approach is to use parallelized processing systems, automate the processing of the seismic data and focus on the generation of pass/fail attributes, allowing onboard personnel to concentrate on problems that really need their attention. Attribute maps are used as the primary interface for QC analysis. The status of both sources and receivers is conveyed by colored dots representing the attributes and can show basic acquisition status or pass/fail status for QC metrics (Figure 2).

FIGURE 2. Integrated, comprehensive, configurable and easy-to-use tools and workflows provide a paradigm shift in automated QA/QC capabilities and data delivery. (Source: ION)

The system architecture allows the user to click on the colored dot, drill down to view the problem and take corrective action as necessary. The display also provides a current view of the overall progress of the survey. The whole system is cloud-enabled, allowing this view to be shared with other users onshore. As only attributes are being shared, data bandwidth requirements are minimized.

Conclusions

A new integrated system architecture, designed from the ground up to address OBS inefficiencies, is helping to increase the value of OBS data through improved data integrity and faster data delivery, reducing HSEQ exposure rates through de-manning of operations and improving the economics of OBS by delivering large gains in operational efficiency.

石油圈

石油圈