An ESP gauge helps eliminate monitoring system failures.

For oil and gas operators, maximizing the value of producing assets through optimized field operations is vital, particularly in an era of fluctuating commodity prices. Ensuring optimal uptime and production from electric submersible pumping (ESP) systems, for example, is only possible with reliable and real-time access to downhole pump and well condition data. And as a result of the industry’s push to digitize operations by coupling advanced downhole sensors with real-time diagnostics solutions, operators can improve production at lower lifting costs.

Historically, reliable data delivery was threatened by electrical disturbance or failure in the downhole ESP system—15% of wells typically lose data communications due to a ground fault that cuts off transmission of pump-related data from the downhole gauge via the ESP cable. While the ESP might still be running, the interruption of data transfer to surface means that valuable insight into pressures, fluid levels and temperatures are unobtainable.

Without access to downhole data, operators were left with two options: 1) conduct a full workover to retrieve and replace the ESP or 2) continue to run the system blind but potentially at lower pumping rates to prevent motor overheating and pump-off. Loss of data due to ground fault might result in an up to 25% reduction in production output compared to a pump optimized with a live downhole gauge.

Ending data loss due to ground faults was the motivation behind the development of the Zenith ground fault immune (GFI) ESP gauge from Baker Hughes, a GE company (BHGE). The gauge employs a unique power and communications system to secure high-value data, even in the event of an electrical failure in the ESP system.

Collaborative development

The Zenith GFI ESP gauge was developed in collaboration with a Middle East operator with a large installed base of ESPs and extensive history of problematic in-well ground faults. The operator needed a gauge that would help increase production by improving access to downhole data from all ESPs running in the field.

In field testing, the new gauge allowed successful data recovery throughout several faults that were applied to simulate real-world conditions. At the one-year mark of installation, further testing was conducted with the system successfully recording data throughout and delivering downhole insight to the operator in real time.

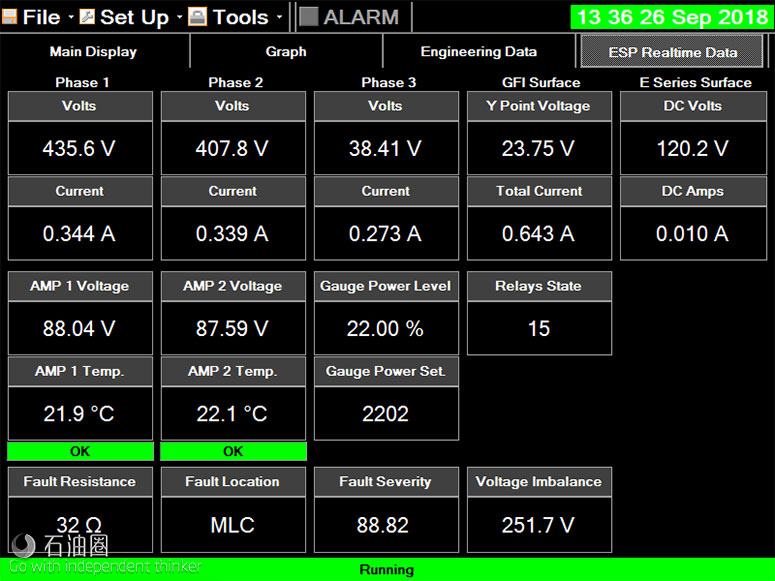

The new GFI software highlights an imbalance on this three-phase power system, with fault resistance of 32 ohm, fault location at the motor lead connection and fault severity at 88.82%. (Source: BHGE)

Since early prototype testing, about 50 Zenith GFI ESP gauges have been installed on a wide range of variable speed drive systems, switchboard drives and pumps for operators across Thailand, the Middle East, Africa and Latin America. In addition to standard gauge parameters, the GFI system’s measurements have been developed to continuously monitor the ESP power system and cable condition over the life of the well and pump. Operators are looking at the technology to assist in real-time electrical diagnosis and prediction of ESP failures as well as to improve ESP runlife by using this new information to help identify the root cause of failures.

Additionally, the GFI system pinpoints the location and severity of a cable fault in the well, enabling informed decisions to be made regarding problematic pumping systems. And with high-speed data remaining available when an ESP fails, operators can ensure that reservoir buildup data are captured when the pump shuts down—insight they would otherwise lose with traditional gauge technology installed.

Incorporating lessons learned

Since initial trials and installs, gauge specialists in the Zenith product development team have leveraged test results and early field experience to enhance the system for a broader range of operating applications. Recent development work aims to position the GFI gauge as the foundation for a new generation of sensors.

Specific improvements to the GFI system since the initial launch include reliability and safety upgrades to the gauge components. The system now includes a single-surface enclosure combining multiple surface fixtures into one unit, reducing more than 40 surface connections on the original system to only seven, markedly simplifying installation.

The system’s original software also has been upgraded with a more stable, scalable program written for industry- standard platforms. The new software, vetted by BHGE cybersecurity experts, brings an improved user interface and delivers a wider range of diagnostic data. As a result, users are gaining faster access to key well and pump information.

Operational data delivered by the Zenith GFI ESP gauge can be integrated into BHGE’s Sabio ProductionLink artificial lift monitoring solution for improved communication and collaboration between engineers and operators. The advanced digital solution can be used to determine appropriate courses of action to improve production profiles and extend system reliability.

The GFI gauge remains the only gauge that is immune to ground faults and is compatible with all manufacturers’ ESPs in the marketplace.

Ensuring ESP reliability

The GFI gauge delivers value to the ESP monitoring landscape in field applications by providing greater reliability and uptime in several ways. By transmitting realtime sensor data after an electrical fault has occurred, the gauge lets operators continue to optimize their production rather than possibly ramping down their pumping rates due to a lack of downhole information.

Operators also are using the gauge to monitor the condition of the ground fault and use the information to guide their decisions on which corrective actions to take. For example, the data help the operator lower the power going to the ESP to remove some of the stress on the cable and motor, which affords more time to plan intervention and deploy a workover rig to the well.

The longest-running Zenith GFI ESP gauge remains the very first installed; it was installed in 2013 for the same Middle East operator who collaborated on the prototype development. Growing numbers of operators are gaining from the benefits the Zenith GFI gauge brings to ESP operations. In one case, the system demonstrated its value in a producing well suffering ongoing scaling and buildup issues in the pump. Following a cable fault four months after commissioning, the team was able to monitor and knowledgeably manage acid injection operations using real-time data from the GFI gauge, despite cable fault conditions. This completion would have been pulled or run blindly if a non-GFI sensor had been installed.

Meanwhile, the pace of new gauge installations continues to rise, and the number of installs is expected to double by mid-2019. Such growth is a testament to both the industry’s ongoing need for digital solutions that optimize production and the benefits that collaboration between service companies and operators provide in driving greater asset value.

石油圈

石油圈