Weatherford has launched a single-trip openhole cementing sidetrack system capable of initiating sidetrack operations without the need of a cement plug. The company’s AlphaST, is designed to increase operator flexibility, eliminate multiple trips, and avoid costly cementing operations. The new tool is the industry’s only single-trip openhole cementing and sidetrack system. “For operators, AlphaST means you will never again need to sidetrack from a cement plug,” said Dean Bell, Weatherford’s president, well construction. “AlphaST enables operators to avoid the cost and time of setting a cement plug; waiting on cement to dry and time drilling. The bottom line is opex savings equal to days of rig time.” For an operator in the Permian basin, previous sidetrack attempts with conventional cement plugs failed in a hard formation, requiring multiple trips in the hole resulting in damaged directional bottomhole assemblies. Weatherford’s re-entry engineers reviewed the application and installed the AlphaST system. After landing at the required depth, the team set the inflatable production packer to anchor the whipstock, and drilled off the formation in a single trip, saving the operator 29 hours of rig time and more than $100,000 of operational expense.

Applications

• Initiating efficient and reliable lateral departures in openhole wellbores

• Kicking off in hard, highly compressive formations where standard drilling methods are ineffective

• Increasing reservoir exposure through extended-reach drilling

Features and Benefits

• The AlphaST single-trip openhole sidetrack system can set, cement, and drill off in the same run.

• The system’s IPP® injection production packer provides a full 360° of contact against the formation to securely anchor the whipstock system.

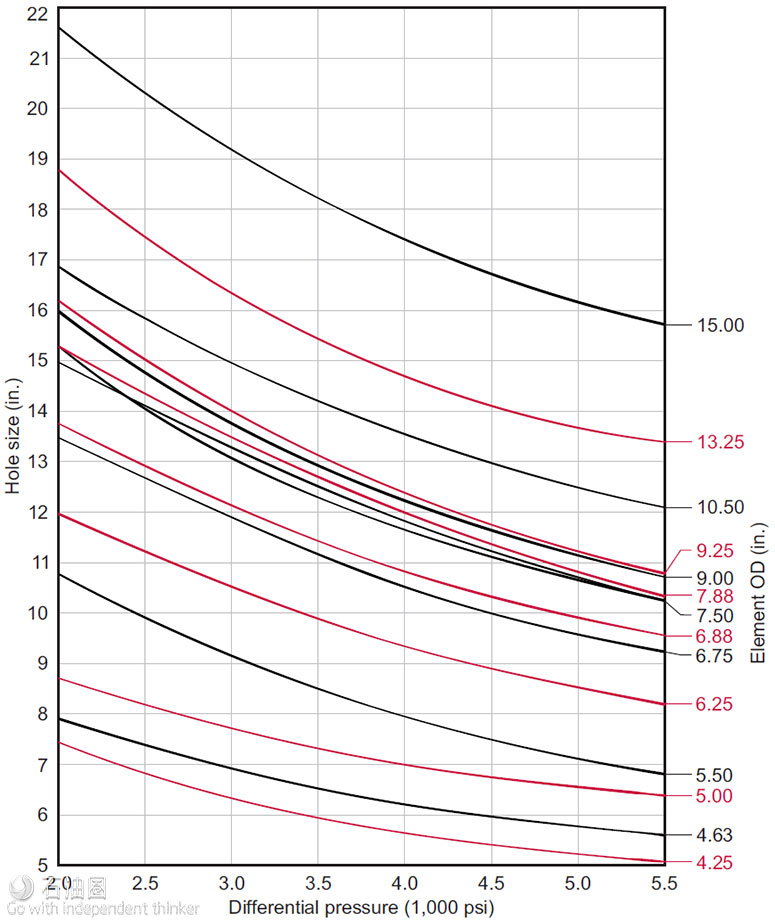

• The IPP packer has a high-strength elastomer element and a slim diameter—smaller than the concave or milling bottomhole assembly (BHA)—for drifting through borehole restrictions. An optional high-temperature elastomer can be used to enhance IPP performance in extreme environments.

• A copper flow tube within the whipstock concave facilitates pumping cement below the whipstock.

• Two mills on the drilloff BHA facilitate a quick departure from the original wellbore.

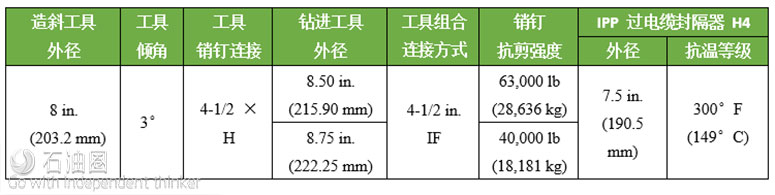

• The whipstock concave uses a single 3° angle for a smoother transition into the sidetrack without steps or ledges, which enables operators to run drilling BHAs that use short-tooth or PDC-style bits immediately after initial whipstock installation.

Tool Description

The Weatherford AlphaST single-trip openhole sidetrack system increases operator flexibility, eliminates multiple trips, and avoids costly cementing operations. This system consists of an IPP injection production packer anchor, a low-angle whipstock, and a twin-mill drilloff BHA. The IPP anchor enables the operator to position the lateral departure in the openhole wellbore without need of a false bottom or cement barrier. The single-angle 3° whipstock creates a smooth transition to eliminate BHA geometry issues on subsequent trips. A lead mill and flex mill initiate the kickoff. This reliable, field-proven openhole whipstock, anchor, and milling system enables operators to access the pay zone in the shortest possible route.

石油圈

石油圈