Deep Imaging today announced the first and only real-time solution for tracking fluid as it’s pumped through the wellbore and out to the fracture tips during a completion job. As a result, upstream companies can validate models and successful stages while identifying, fixing or avoiding problem stages as they occur.

The prevailing approach to developing shale is delivering mixed results. Drilling larger wells more closely together has reduced per unit costs, but many new wells are underperforming production expectations by as much as 30%.

The problem is the industry is acting on limited data to make intricate operating decisions. Without the right instruments to see what is happening during a well completion, operators are experiencing frac hits and are unable to identify poor cement jobs, failed plugs and unclosed zippers, all of which leave valuable resources in the ground. With the ability to see a frac job in real-time, operators can now truly optimize full-field development.

At around the cost of a single frac stage, payback on this surface-based technology is quick and the upside is large, especially considering not “closing” a zipper frac can mean up to 30% of the reservoir is untapped. With projected sales of $500 million from a development project, operators utilizing fluid tracking could capture the $150 million that would otherwise be left behind.

Among other benefits, the technology also enables operators to determine which downhole products and strategies are causing problems to help improve their purchasing plans. If an operator understands they have failures 20% of the time with a certain type of plug, they can find a better provider.

The most advanced frac diagnostic tool in the field

Identify the problems in your wells and improve profitability

We identify frac hits, bad cement, plug failures, open zippers and other problems in your wells that are the cause of under performance.

Clients have never had these insights before. We provide these answers by tracking frac fluid in real-time so you can see where you’re actually placing fluid—and it’s not where typical models predict.

When you know your problems, you can solve them and get back on track. So let’s fix this together.

A SIMPLE PROCESS WITH BIG RESULTS

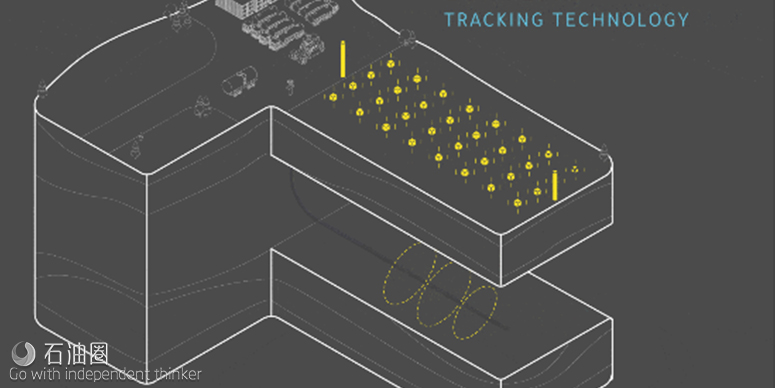

We setup our project in the meadow over your horizontal, never entering the well site or interfering with operations. We then create electric fields. As the frac fluid moves, we measure the changes to these fields. It’s a surprisingly simple, yet effective process.

People often ask if it’s dangerous to go near where we are injecting and receiving the current—and the answer is no. It’s actually walk-safe as our sites are non-intrusive and HSE friendly.

Insights you’ve never had before

Find out what problems you’re facing as you watch where your frac fluid is going in real-time. Gone are the days of just cranking up the dials in response to poor production. Now you know what the problem is so you can address it with the right solution improving economic returns.

Effective diagnostics to identify and fix problems

With accurate knowledge of where your frac fluid is going you’ll have valuable insights into the reality of your project.

If things aren’t going according to plan, we help you discover why so you can efficiently fix it. For example, if your child wells are underperforming you’ll quickly know why so you can make the necessary adjustments or make the decision to move on.

Problems during a project can create lots of waste with negative economic impact—by fixing problems early you can dramatically improve performance.

Improving your economics

When you can identify the source of a problem early, you can fix it faster. Deep Imaging empowers you to see where the problem is so you can address it, stop wasting resources and time, and save money

Deep Imaging is the only company that directly tracks frac fluid as you inject it into the well and when you pull it back out. We do this by creating a subsurface electric field and measure the changes caused by the moving fluid. Our measurements are direct, eliminating any guesswork.

Our technology lies in the meadow over your horizontal—it is entirely surface-based and off the pad. We are the lightest, most low-impact diagnostic tool in the industry and never enter the well site or interfere with operations.

“Deep Imaging allowed us to see where the frac fluid went during our completion, and where the fluid remained after the pumps shut off. This led us to make significant design changes and optimizations in our program.” – Sam, Jones Energy

石油圈

石油圈