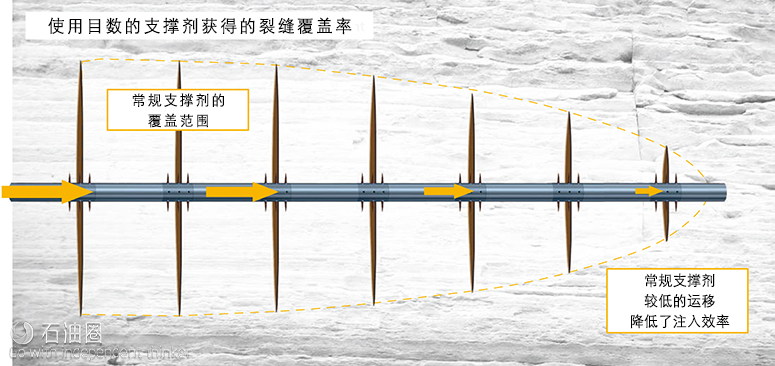

Microfractures created within a complex fracture network close shortly after the release of hydraulic pressure and heal sometime thereafter. Propping these microfractures open will maximize their productivity. Conventional proppant is too large to fit into these microfractures and its transport characteristics limit how far it travels into the stimulated area, limiting Propped Reservoir Volume? (PRV?) and ultimately, recovery and return. NANOMITE? C ceramic microproppant is a fraction of the size of the smallest proppant commonly deployed. Production can be improved if secondary and microfractures are propped open.

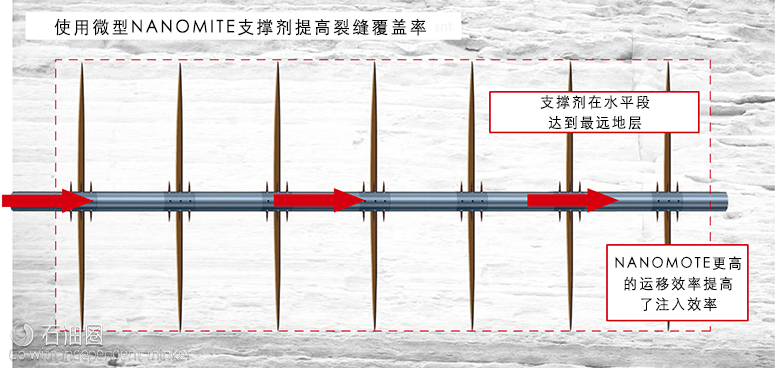

NANOMITE microproppant increases the propped fracture height, width and length, maximizing the productive reservoir contact area. Long-term production gains can be achieved by propping open microfractures in the stimulated areas so that they contribute to hydrocarbon flow, increasing production, estimated ultimate recovery (EUR) and return on investment (ROI).

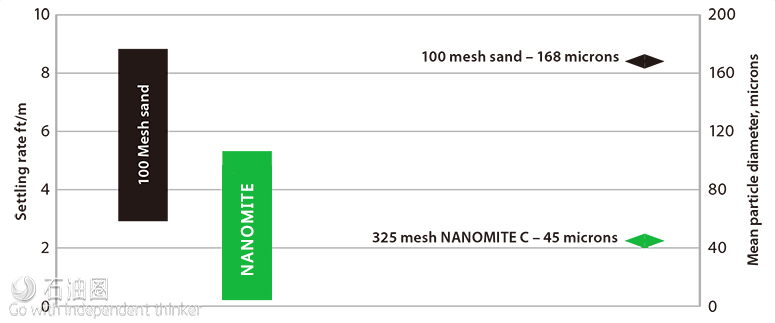

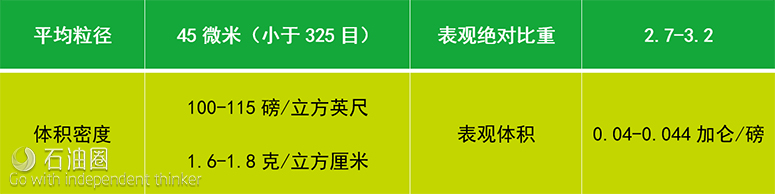

NANOMITE microproppant contains a broad range of particle sizes within the 150/635 mesh (100 μm to 20 μm) range. The smallest NANOMITE particles are over 5 times smaller than the smallest particles in 100 mesh frac sand. As a result, it provides much of the benefits of 100 mesh proppant, while propping open even the narrowest secondary fractures and microfractures.

The broad range of small particle sizes results in varied settling velocities, ensuring NANOMITE particles link the benefit in the primary fractures to the furthest tips of the microfractures. The average settling rate of 100 mesh sand is over twice as fast as NANOMITE particles. The small size and enhanced transport characteristics enable the microproppant to navigate tight angles experienced in complex fracture networks, reaching otherwise untapped microfractures contributing increased production. NANOMITE particles transport well in slickwater fluids to improve reservoir contact and fracture conductivity in microfractures. This can be further enhanced by utilizing special fluids which support farther penetration.

NANOMITE C microproppant is high quality ceramic proppant that has the compressive strength and durability to maintain fracture co onductivity and more space for hydrocarbon flow under closure stress.

NANOMITE microproppant can be used in conjunction with CARBOAIR? high-transport, ultra low-density ceramic proppant technology to create a unique solution to increase PRV and estimated ultimate recovery. CARBOAIR technology travels further into primary fractures increasing PRV as it has an Apparent Specific Gravity (ASG) of 2.0 and a settling velocity 25% slower than comparably sized sand. Additionally, the technology exceeds the conductivity, strength and durability of sand, which maximizes the production rates and recovery from the increased reservoir contact. Both technologies can be integrated as part of an overall proppant pack.

石油圈

石油圈