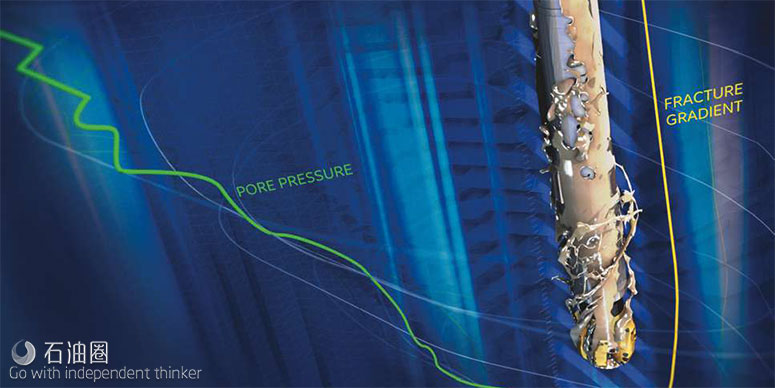

Low-pressure-impact drilling fluid reduces risk in narrow pressure windows

Baker Hughes, a GE company (BHGE), has released its DELTA-TEQ low-pressure-impact drilling fluid, a nonaqueous formulation that enables operators working in narrow pressure windows to meet their drilling objectives by significantly reducing the risks associated with this activity, according to a company product announcement. In challenging wells such as those offshore, pore pressure, fracture gradient and complex geometry combine to create a narrow operating window. Numerous operational problems such as excessive surge pressures, pressure spikes due to pump initiation pressures, complicated equivalent circulating density management and the inability to effectively control drilling parameters can result in costly and time-consuming events. The DELTA-TEQ fluid creates a nonprogressive gel structure that reduces hydraulic impact with a rapid-set/easy-break profile that maintains fluid integrity if operations are paused, mitigates pressure spikes when circulation resumes and protects the formation from surge pressures when running casing. In addition, the DELTA-TEQ fluid can manage hydraulic impact by maintaining the right viscosity in the right areas of the well for optimal hole cleaning and penetration rates without putting excess pressure on the formation. Like a “viscosity clutch,” it engages viscosity at low shear rates and disengages at high shear rates.

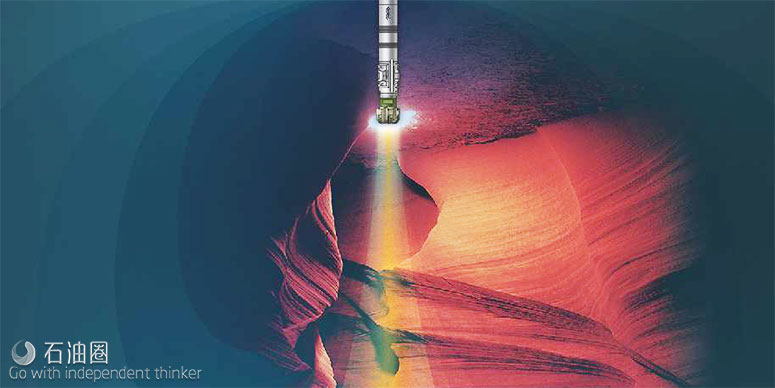

New look-ahead-while-drilling service provides real-time data

Schlumberger has released the IriSphere look-aheadwhile- drilling service, which provides electromagnetic (EM) technology for detecting formation features ahead of the drillbit in oil and gas wells, according to a press release. The service is designed to reduce drilling risks and improve efficiency by providing data ahead of the bit in real time. IriSphere uses EM-based resistivity measurements more than 30 m (100 ft) ahead of the drillbit, which are then compared to a prepared model that incorporates offset and other data to reveal a true downrange representation of the formation while drilling. This enables operators to make proactive decisions rather than reacting to measurements at or behind the bit while drilling wells. More than 25 field trials were conducted with the IriSphere service, which included successfully detecting reservoirs and salt boundaries, identifying thin layers and avoiding drilling hazards such as high-pressure formations that can lead to wellbore stability issues.

New LED lights up onshore drilling rigs’ hazard areas

Emerson has released a new LED for the oil and gas industry to easily and safely illuminate land-based drilling rigs, a press release stated. The Appleton Rigmaster LED linear luminaire streamlines the cumbersome and time-consuming task of installing and maintaining bright, energy-efficient lighting in hazardous areas on drilling rigs. The LED weighs only 10 lb, making it significantly lighter than similar fixtures that can weigh as much as 30 lb. The LED light delivers 8,000 lumens of uniform lighting to promote a safer working environment. Moreover, the LED’s wide distribution of light translates into fewer fixtures being needed in the rig’s mud pit, shaker, cellar and derrick. The Appleton Rigmaster LED provides installation flexibility in hazardous locations by offering a variety of mounting options that are well suited for retrofits as well as new rig builds.

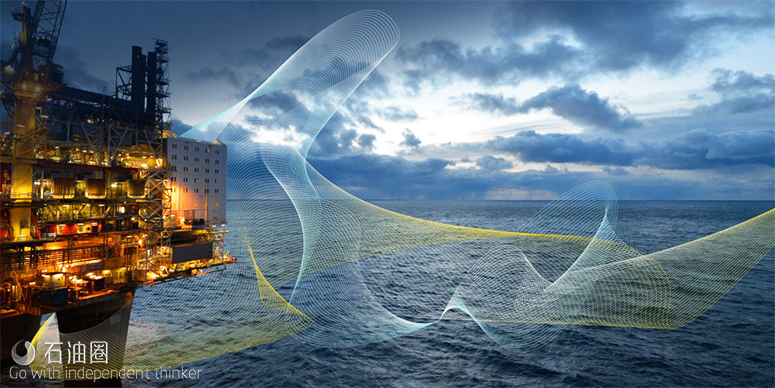

New technology tackles subsea challenges

Technology to enhance operational effectiveness while reducing risk and preventing interruption in pipeline production has been developed by WFS Technologies, a press release stated. The patented Seatooth PipeLogger is an integrated pipeline, umbilical, risers and flowlines temperature monitoring and data transfer solution that can provide real-time monitoring for offshore and subsea assets. It has been previously used to reduce the risk and operational costs associated with coiled tubing fatigue, producing savings more than £1 million in a single installation.

Expanding subsea intervention capabilities

Expro has expanded its subsea intervention capabilities by introducing two new well access solutions in addition to its subsea landing string system technologies, according to a press release. The Intervention Riser System (IRS) can safely establish and maintain well access throughout riser to surface operations, replicating the functionality of the BOP and providing a safe and reliable means of well control connected directly to the production tree. With increased coiled tubing cutting and disconnect capability, the IRS provides an alternative dual barrier, thru-tubing system. The new Riserless Well Intervention System provides a reliable wire through-water integrated solution for carrying out cost-effective intervention and/or abandonment operations on all types of subsea wells. With a dedicated intervention vessel, all operations, deployment and retrieval can be carried out in a safe and efficient manner

Magnetic referencing system for MWD surveys

CGG Multi-Physics has announced the immediate availability of precalculated MagCube in-field referencing models for MWD surveys over seven U.S. onshore basins and plays: Bakken, Eagle Ford, Haynesville, Marcellus, Niobrara, Permian and Woodford, according to a news release. These datasets are available for licensing or extraction on a well-by-well basis with one-day turnaround. CGG’s MagCube magnetic referencing system combines a global geomagnetic reference model with local magnetic survey data to deliver declination (dip), inclination and total field values at depth. These cubes of subsurface vector magnetic field information form a reference frame for MWD surveys in directional drilling. Accurately knowing a well’s trajectory while the well is still being drilled could save costly sidetracks and prevent collisions with other wells in tightly drilled shale plays.

Miniature optical gauge enhances intervention surveillance

Well-SENSE has released a compact, disposable optical pressure-temperature gauge as part of its FiberLine Intervention (FLI) system, a press release stated. The Well-SENSE optical gauge widens the well surveillance application envelope for FLI, both on and offshore, and offers operators a low-cost and disposable alternative to both permanent downhole sensors and more traditional electronic logging devices. It can result in savings between 50% and 90% compared to conventional logging methods. The fiber Bragg grating based device is a robust optical gauge which does not require batteries, external connections or power supply. It is integrated into the fiber line and is ideally suited to well surveillance activities in harsh environments around the world, including HP/HT applications. The new gauge has the capability to measure up to 10,000 psi and 150 C (302 F), with an option to enhance this further to 20,000 psi and 300 C (572 F). Well-SENSE developed this technology in partnership with optical sensor company Fibos.

Drillpipe cleaning ball helps avoid 11 days of rig time costs and risk

Coretrax’ drillpipe cleaning tool, the CX-Ball, eliminates the need for costly equipment or hazardous manual handling, a press release stated. Based on an average time saving of 8 minutes per ball, this in total has saved 278 hours of rig time, equivalent to 11.58 days since the product was launched in 2014. In one North Sea campaign, it has been used consistently for the last 74 well abandonments saving 57.6 hours of rig time alone. The CX-Ball is encased in a soluble material that temporarily restricts the shape of the ball. This allows it to be easily and accurately deployed by a launch tube directly into the drillpipe. When the CX-Ball comes into contact with water, the ball expands and returns to its original shape. The high parting stretch ratio of the foam ball allows it to pass through small restrictions undamaged as it is pumped downhole.

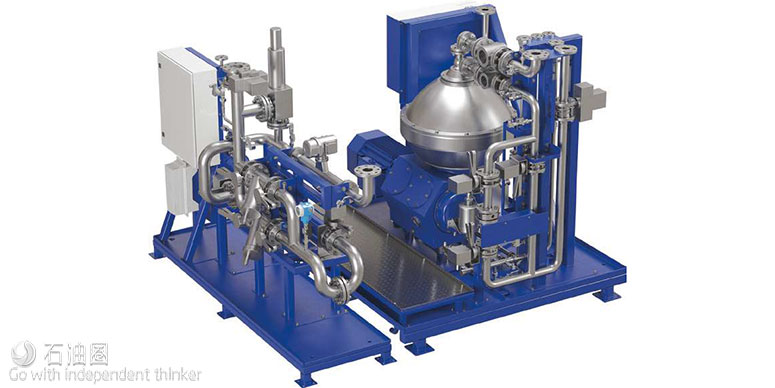

New water cleaning system offers closedloop function

Alfa Laval PureSOx gives the option of scrubbing in closed loop, either by choosing a fully equipped hybrid system or by installing a hybrid-ready system that can be upgraded for closed-loop operation later, according to a press release. With the launch of a modular new PureSOx water cleaning system, these possibilities become even more attractive. Though few in number and limited in scope, local bans on openloop scrubbing have intensified the interest in hybrid scrubber solutions with closed-loop functionality. While marine customers are focused on complying with today’s needs at minimal cost, there is peace of mind in the ability to upgrade if regulations should become more stringent. Both considerations are integral to the new PureSOx water cleaning system.

Low range, selective VOC analysis device

Dräger has released its X-pid 8500 portable gas measurement device to the U.S. market, a press release stated. The gas chromatography-photoionization detector allows selective measurement analysis of predetermined compounds, such as benzene, butadiene and other volatile organic compounds (VOCs), and provides results in as little as 30 seconds. The X-pid 8500’s operating design and wide compound range for selective monitoring allows the device to detect and quantitate more than 19 toxic target compounds with the push of a button. In addition, users can add their own substances to the target compound database that would allow for detection. The device’s intuitive user interface makes this technology accessible to a broad group of users with no extensive training required.

石油圈

石油圈