Unity, provider of well integrity technology, services and engineering solutions, has launched the industry’s first multi-functional, near-surface intervention system following a successful commercial project for a major operator in Northwest Africa.

In its first deployment, the Surface Intervention System (SIS) was mobilized off the coast of Tunisia to set two frac sleeves on two wells. Each sleeve was successfully set in under three hours, including rig-up and rig-down time – a significant speed compared to the c.24-hour schedule for conventional intervention methods.

Gary Smart, Unity CEO said, “Unity is investing in technology and services that are designed to deliver significant benefits to the oil and gas industry. Working closely with our customers, we recognized a clear opportunity to develop a multi-functional shallow intervention system which combines heavyweight capability within a compact and mobile package. Being simple to operate, compact to ship and fast to deploy, the SIS offers cost savings of up to 75% when used as an alternative to conventional equipment. We believe this is a ground-breaking technology offering rapid and streamlined operations which will open up new doors to improved efficiency gains for operators.”

Wireline or coiled tubing intervention often requires multiple vendors with considerable manpower, heavy well control packages, and a large wellsite footprint resulting in significant cost and risk for the operator, especially offshore. While this equipment is necessary for deeper well intervention, the SIS provides a refined and more cost-effective solution for shallow operations.

With the option to include an integrated well control package, the SIS can be used across a variety of operations including plug or tubing hanger setting, Xmas Tree removal, well inspection, milling and well-bore clean out. Consecutive tasks can be performed during the same deployment, with the system operated by just two people, increasing efficiency.

The SIS is fully-compatible with industry standard tools. This enables simple switching between functions using sectional hollow rods at the wellsite. It can operate in pressures up to 10,000 psi and has a powerful hydraulic motor, driving a push, pull and rotate function which can rival wireline or coiled tubing capability.

According to the Oil and Gas Authority’s ‘Wells Insight Report 2018’, well integrity problems were the single biggest cause of production losses, accounting for 43% of the total 33 MMboe loss, of which 10 MMboe was due to wellhead, xmas tree and annulus failures.

Mr Smart added, “Near surface well integrity is extremely influential in avoiding and recovering production losses, so we see a clear opportunity for the systems use in safeguarding the integrity of producing wells in the UKCS and across global oil and gas regions.

“The SIS is also ideally placed to assist in the end phase of well P&A activity through plug setting and the removal of xmas tree and wellhead surface equipment. In addition, it can be used to carry out inspection and remedial work of the internals of the surface equipment and tubulars prior to removal.”

The commercial launch of the SIS marks another significant milestone for the company since it acquired Simmons Edeco Europe in December 2018 and changed its name from Well-Centric to Unity. The deal created Europe’s largest independent supplier of well integrity services.

The business currently employs more than 120 skilled personnel across its bases in Aberdeen and Great Yarmouth, UK and Esbjerg, Denmark.

Unity, alongside Well-SENSE, ClearWELL and Pragma, is part of FrontRow Energy Technology Group. A group of complementary upstream oil and gas technology focused businesses that are bringing new solutions to market to meet industry challenges and reduce costs.

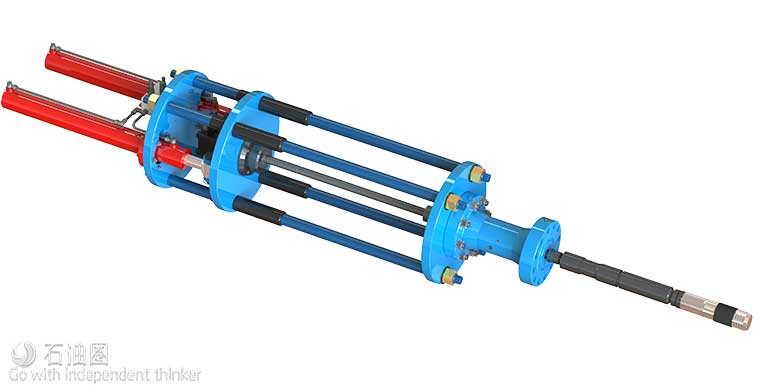

The Surface Intervention System (SIS)

• Self contained, hydraulically operated, near surface intervention system.

• Quick, easy and safe to rig-up and rig-down

• Multiple intervention operations can be conducted consecutively, increasing operational efficiency

• Requires fewer personnel (the same personnel can carry out remedial tree repairs)

• Reduced footprint, operable in smaller, restrictive spaces

• Barriers provided for live-well entry

• Reduces requirement for traditional intervention technologies

Functions

• Milling Drills through stuck or inoperable gate valves and other near wellhead blockages up to 7” in diameter

• Cleanout A wide selection of tool attachments allows multiple clean-out operations to be carried out using the SIS including scraping, brushing and debris and swarf removal.

• Inspection The SIS can be used to carry out internal inspection of near surface areas such Xmas tree internals and tubing hanger profiles using memory callipers or a memory camera.

• Plug Setting With impressive push (70,000 lbs) and pull (40,000 lbs) capacity, as well as the ability to hydraulically rotate the SIS can be used to set and retrieve a wide range of tubing hanger and tubing set plugs.

石油圈

石油圈