可溶解压裂球能够避免压裂后的磨铣操作,低成本压裂砂也同样发挥了降低成本的作用。

编译 | 惊蛰 影子

当前,油气勘探与开发公司优先考虑投资非常规资源,服务公司也紧跟风潮,加速推进完井技术发展,以满足开发商不断增长的技术需求。在持续的技术创新中,开发商的态度非常明确,即进一步降低成本是绝对必要的。“情况不再只是新技术可以为运营商带来什么改变,而是它将如何影响桶油成本。”Enventure的销售总监Mark Villarreal说。

为了实现降低成本的目标,许多开发商逐渐开始使用作业区附近的压裂砂进行压裂。 这可以将支撑剂成本降低50%以上。Wood Mackenzie预计美国支撑剂市场的一半已经被作业区附近砂子占据。

对于开发商来说,在作业区附近采购压裂砂有利于降低成本,但对一些压裂砂供应商来说却压力骤增,尤其是那些远离作业区且此前供砂量大的厂商(以美国北方的压裂砂供应商为代表)。Forbes说:“尽管这些公司目前还在向各地的作业现场提供砂子,例如北美的Bakken和Marcellus区块,但可以预见的是,他们即将迎来“寒冬”。现在是个过渡时期,这些供应商仍在销售大量的作业砂以补充作业地区砂产量的不足。尽管开发商已对附近地区砂源表现出更大的兴趣,但由于产能不足,他们还要向外界供应商采购。随着当地越来越多的砂场开发,北方压裂砂供应商将会面临更大挑战。”…“鉴于此,预计北部的供砂商会选择开拓加拿大或美国北部其它国家的市场。”

“另外一个开发商逐渐采用的将本方式是完井材料自主采购。在以往的作业中,压裂服务商会提供压裂砂、物流、化学品、燃料等一系列压裂用消耗品,但现在开发商逐渐摒弃了这种作业方式。在过去几年中,自主采购是一个重大的趋势,而且取得了不错的效果,作业效率、控制能力和成本都得到了优化,越来越多的开发商都更倾向于这种模式。不远的未来,在大多数情况下,压裂公司或许只负责提供压裂泵和作业人员。”

另外一个新趋势是电动压裂的兴起。开发商发现,通过电力代替柴油驱动压裂设备,能够降低成本、提高效率。无论是压裂时间或是每天的压裂级数,电动压裂都能提高15%-20%的效率。此外,电动压裂还具有设备占地面积小、排放少、噪音低等优势。

目前,已经有几家服务商提供电动压裂服务,他们称其为“清洁压裂”。虽然此类设备的投入非常巨大,但这是压裂行业不可避免的趋势,改变正在发生。

优异连接性能 解决高温重复压裂难题

为了满足提高产量的目标,水平井的长度逐渐增加,压裂速率和压裂砂、支撑剂用量也随之提高。同时,作业范围也在逐渐拓宽,尤其是高温环境重复压裂作业频率逐渐提高。为了满足此类作业的需求,Enventure近日升级了ESeal 3.0 RF尾管系统,相比于上一代产品,其连接强度提高了16%,高温作业系统的连接强度较上一代产品提高了40%。

Enventure近日升级了ESEAL 3.0 RF尾管系统,相比于上一代产品,常规尾管工具连接强度提高了16%,高温系统连接强度提高40%。

Enventure的Villarreal表示,早在几年前重复压裂没有获得像现在的热度时,许多开发商已经开始选择其作为提高产量的方式,尤其是在Eagle Ford和Permian地区。在过去几年中,许多开发商以不同的方式进行了重复压裂实验,获得了许多有价值的经验和知识。

“在2014-2016年间,许多重复压力作业是通过化学药剂和特殊转向技术实现的。在随后的2017年至今,开发商逐渐意识到这些重复压裂方案效率较低。Enventure相信大多数开发商也得到了相同的结论,那就是机械转向技术采是最佳的压裂方法。在该技术的帮助下,废弃射孔簇被封堵,通过封堵-射孔技术即可实现新产层的压裂激活。”

ESeal重复压裂系统使用可膨胀机械转向器,每个转向器都具有最大化的内径,可用于隔离现有射孔簇,同时创造最大的液体流动内径,可建立最佳的油藏-井筒连接。

Villareal说:“重复压裂尾管也可以用于极端有限空间(XLE)作业的连接应用,利用ESeal执行XLE作业赋予了开发商更高的灵活性,水平段可以更长,整体作业成本也可降低20-30%。”

压裂短节 消除连续油管应用

近日,NOV推出了BPS Maxx技术,其建立在爆破系统基础之上,可以建立油藏与井筒之间的连接,为后续作业打下基础,例如井下封堵桥塞部署,创造自动流道等。

近日,在Anadarko的一次作业中,开发商想要提高油藏采收率,提高封堵射孔作业的效率,降低风险。

BPS Maxx井底激活短节通过液压激活,专用于水平井完井中底部压裂液注入,无需额外的干预作业。该工具可以消除连续油管下入射孔枪或电缆下入牵引器操作,建立井底与油藏连接更容易。

NOV完井工具经理Reza Rastegar说:“此项技术改变了传统的作业方式,井筒产率更高。它消除了连续油管作业,将之前影响增产的区域转变为新的投资点。”

相比于上一代BPS产品,该短节的内部流动面积高达3倍,降低了残留于套管内固井碎屑堵塞井筒流道的风险。其在固井和裸眼井中都可以应用,可以单一使用也可以多个共同使用,创造多级射孔完井。

在三个BPS Maxx短节中分别使用连个套管短节连接,创造了趾部第一级射孔簇,消除了趾部初始活化和其它准备工作的必要。在BPS Maxx的帮助下,第一级产层的压裂泵入速率高达96bpm,地面最大作业压力达到了8800psi。

消除井筒趾部的初始增产层能够改善油藏与井筒的接触,降低造斜长度,消除第一级产层封堵-射孔作业风险。

今年, NOV 的Setter系列复合材料压裂桥塞在Permian实现了应用。一家开发商想要对比几种不同的复合桥塞应用效果,评估标准包括磨铣时间、是否能够下入指定深度等。

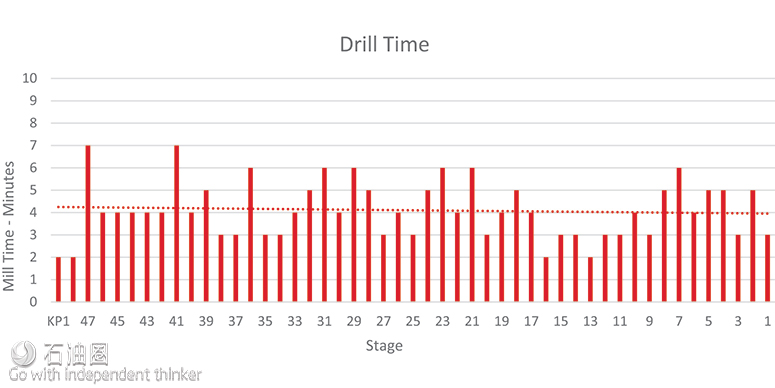

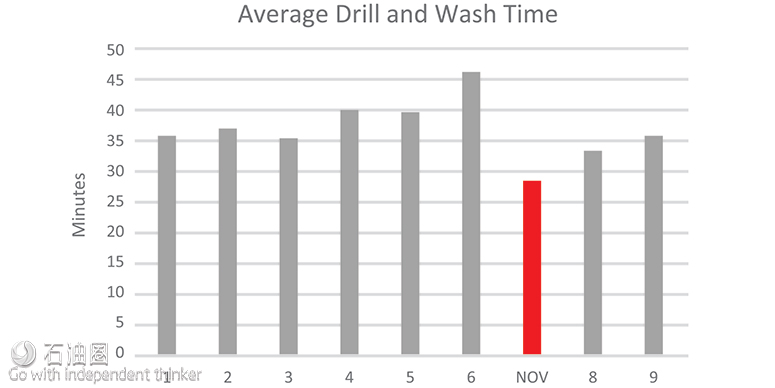

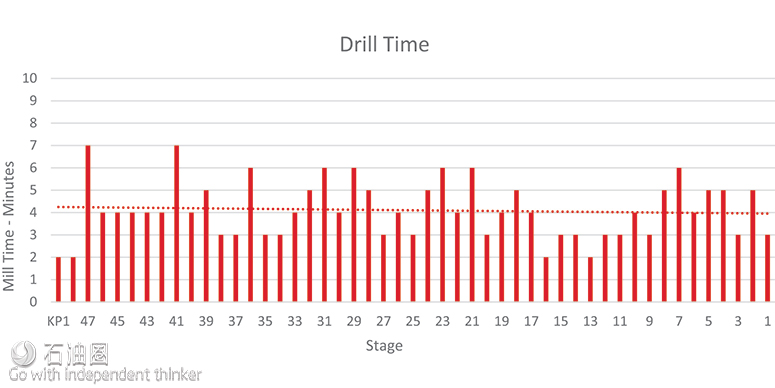

49个Setter系列桥塞的平均磨铣和清洗时间为4.1min。

Setter系列桥塞采用紧凑型设计和复合材料结构,平均磨铣和碎屑清洗时间为4min。其卡瓦采用齿形设计,在密封过程中受力更加均一,同时降低磨铣过程发生问题的几率。

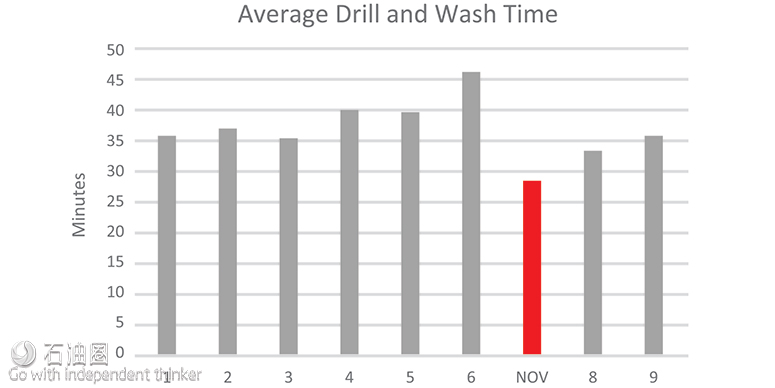

该开发商利用多口井对九家不同桥塞供应商的产品进行了测试评估,结果显示,Setter系列桥塞磨铣和清洗时间最短,且100%都达到了设计深度。

Setter系列桥塞实现了快速磨铣和冲洗,图中所示为Permian一家开发商对于九种桥塞的磨铣、清洗时间测试结果。

作业过程中,桥塞的下入速度高达500ft/min,泵入速率达到12bbl/min,49个桥塞的平均磨铣时间仅为4.1min。

For English, Please click here (展开/收缩)

Upgraded Connection for High-Temperature Refracs

As operators continue to push laterals out farther and farther, fracturing rates have been increasing, as have the amount of sand and proppant used per frac job. Operating envelopes are also being extended, particularly in terms of high-temperature refracturing operations. To meet the demands of such applications, Enventure recently upgraded the connection in its ESeal 3.0 RF liner system. This new standard version has connections that are 16% stronger than the previous generation, while the high-temperature version offers connections that are 40% stronger.

Mr Villarreal with Enventure noted that while refracs are not as hot a topic as it was a few years ago, many operators are still choosing refracs as the way to boost production, particularly in basins like the Eagle Ford and Permian. Further, companies have been experimenting with different ways of refracturing for the past several years and have been gaining valuable experience and knowledge in the process.

“Back in 2014 to 2016, a lot of refracs were being done with chemical or particulate diversion. Then, in 2017, 2018 and now 2019, the marketplace has discovered that’s not really an effective method to refrac with.” In fact, Enventure believes that most operators now agree mechanical diversion is the best way to divert a refrac, he said. With mechanical diversion, all old perforations are isolated, and the interval can be completely refracked with plug & perf operations.

The ESeal refrac system uses solid expandable mechanical diverters. Each can effectively create a new wellbore with the maximum inside diameter for the isolation of existing perforations, thereby providing more flow to the reservoir.

The refrac liner can also be used in conjunction with the extreme limited entry (XLE) fracking technique, Mr Villareal said. “Performing an XLE job with our expandable gives you the means to pump longer stages, which essentially drive down your cost by, in some cases, 20-30%.”

Disruptive Technology Eliminates Use of Coiled Tubing

National Oilwell Varco (NOV) recently launched the BPS Maxx, which builds on the original burst port system that is used to create a path of flow to the formation for future operations, such as running a plug downhole or creating passive flow.

In a recent case study in the Anadarko Basin, the operator wanted to maximize the contribution from the reservoir, while increasing efficiency and minimizing risk during plug and perf operations.

The hydraulically activated BPS Maxx toe initiation sub was designed for use in horizontal completions to establish injection of fluid at the toe without intervention. This also eliminates the need for traditional tubing-conveyed perforating guns or wireline tractors as a means of gaining access to the formation at the toe.

“This is a disruptive technology,” said Reza Rastegar, Completions Tool Operations Manager with NOV. “It drastically changes the process and makes it more productive. It eliminates the use of coiled tubing and turns a zone that used to be an economical barrier into an investment.”

The sub has a flow area that is approximately three times bigger than the original BPS, which reduces the risk of plugging from debris left in the casing after cementing operations. It can be used in both cemented and uncemented applications and can be installed as a single port or in multiples to create a full-stage cluster.

Three BPS Maxx subs were installed with two casing joints in between to create a first frac stage cluster eliminating toe initiation and prep work. The BPS Maxx enabled the operator to frac the first stage with an average stimulation rate of 96 bpm at a max surface treating pressure of 8,800 psi.

Eliminating the toe initiation stage provided more reservoir contact area, and downsizing the shoe track length eliminated the risk associated with plug and perf operations on the first stage.

NOV this year has also deployed its Setter Series composite frac plugs in Lea County, N.M., for a Permian operator that wanted to evaluate drill-out results from multiple composite plugs, including time required for drill-out and plugs tagged on depth.

The Setter Series plugs have a compact design and all-composite construction that allow for an average drill-out time of 4 minutes, as well as less debris to remove from the wellbore. The plugs also feature castellated lower slips for even slip distribution during setting and reduce incidents of plugs not being tagged during drill-out.

Out of the nine plug providers that were evaluated by this operator across multiple wells, the Setter Series plugs had the quickest drill and wash times, and 100% of these plugs were tagged on depth.

The plugs were run and set with speeds up to 500 ft/min and maximum pump rates of 12 bbl/min. Average drill time for 49 plugs was 4.1 minutes per plug.

未经允许,不得转载本站任何文章:

石油圈

石油圈