As previously mentioned, the operating environment plays a role in choosing the right technology. For this examination, the wells were in the Eagle Ford.

The Eagle Ford shale is a unique geological formation, because of its capability to produce both natural gas and oil. The basin covers 20,000 mi2 in south and central Texas, stretching across 24 counties. There are nearly 12,000 producing wells. The majority of these wells are drilled horizontally from multi-well pads.

Like other shale plays, this geological formation has low permeability, preventing natural hydrocarbon flow. Because oil cannot flow easily through ultra-low-permeability rock, high initial production rates from shale formations often decline rapidly. Therefore, an efficient completions program can improve the wells’ longer-term economic viability.

The Eagle Ford has some distinct characteristics that can make production challenging. The play exhibits an extremely tight formation rock matrix. Tighter sections are thin layers of varying compositions and weak interfaces in the rock, meaning that injected fluids become diverted to the paths of least resistance. This feature creates natural fracture variability, requiring more pressure generation at the surface. Treatment pressures during fracturing operations in the Eagle Ford are some of the highest applied during any oilfield pressure pumping operation.

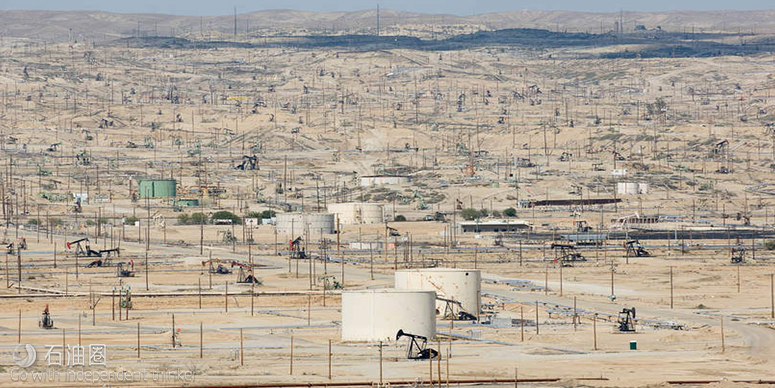

Furthermore, much of the Eagle Ford’s area of operation is in remote expanses with limited infrastructure. Logistics management—which includes moving equipment, people, materials and parts—requires sophisticated coordination. These remote locations can introduce operational complexity, as well as additional costs.

Because of the aforementioned challenges, the operator had to take into consideration the higher treating pressures and logistical complexity when selecting the fluid design. The Eagle Ford operator needed a fluid design that could achieve friction reduction, and maximize proppant transport, while accommodating the pressures and minimizing complexity and costs.

OPERATIONAL SUCCESS

The operator started fracturing operations on a two-well pad. Overall, they had 20 to 30 wells, with approximately 35 stages per well.

For the first ten stages of both wells, the operator used a conventional slickwater treatment, the same design that had been used on previous wells. During the fracturing operations, the operator experienced extremely high pumping pressures, causing equipment shutdowns, NPT and delays. Operator personnel also kept a gel unit rigged-in, on location, as a secondary backup.

For the next 15 stages, the operator switched to a tunable friction reducer. Wellsite personnel started to run the enhanced polymer at a higher loading of 1 gallon per thousand (gpt). To be on the safe side, they kept the gel unit on location. After seeing enough performance results, the enhanced polymer was tuned to run at half the loading, at the concentration of 0.5 gpt. On average, fluid concentrations with ThinFrac MP were 20% less than conventional friction reducers and eliminated the need for guar gel.

The operator saw equal performance with a lower concentration. Consequently, less horsepower was needed at the surface while still ensuring effective results. By reducing the concentration, the operator experienced the same level of viscosity, but the pressures were 10% lower, compared to the slickwater hybrid treatment. This lower rate enabled the proppant to be carried deeper into the fracture network, Figs. 1–4.

To effectively pump the fluids, the company used its unique Gorilla high-pressure pumps. These heavy-duty pumps provide up to 2,700 hydraulic horsepower (HHP) at pressures up to 20,000 psi. The high-capacity fuel tank enables 4 hr of continuous pumping operations at maximum horsepower, reducing refueling and backup equipment requirements. The higher horsepower pump allowed a 16-pump fleet, compared to the standard 20-pump fleet. In addition, because the polymer was a single-fluid solution, no specialized equipment was needed to pump the chemistry, reducing the operational footprint.

Furthermore, when the operator experienced increases in pressure, the friction reducer concentration was run at a higher loading of 1 gpt, to increase the viscosity. The fluid adjustment was made on the fly, with no disruption to the ongoing operations or increasing the surface horsepower requirements. After the first few stages, the operator was confident in the technology’s performance and removed the additional gel unit, eliminating equipment and extra additives, as well as a further reduction to the footprint.

The operator completed 15 stages with the tunable friction reducer. Because the technology could be tuned effectively, the operator was able to complete the 15 stages more quickly and with less downtime than the previous ten stages. The flexible design of the friction reducer allows completion of more stages with less shutdowns and screen-outs.

Overall, production results taken over the first 180 days will show that wells completed with the tunable friction reducer performed better, in terms of initial production and cumulative production, which are normalized by lateral length and proppant volume. In a study of wells within a 5-mi radius of the two-well pad, based on data from RS Energy, 180-day boe produced per 1,000 ft from the ThinFrac MP wells was 27% higher than the non-ThinFrac MP wells, Fig. 5. The operator continued to use the technology on subsequent wells as its exclusive friction reducer and has since fully adopted the enhanced friction reducer for use on all its wells in the region.

CONCLUSION

The study has proven that tunable technology can help achieve greater efficiency gains in developing unconventional reservoirs. Improved well performance can be attributed to the enhanced proppant transport capabilities and greater regaining of conductivity. Finally, cost-savings are seen through simplified delivery, smaller job site footprints and reduction in NPT.

石油圈

石油圈