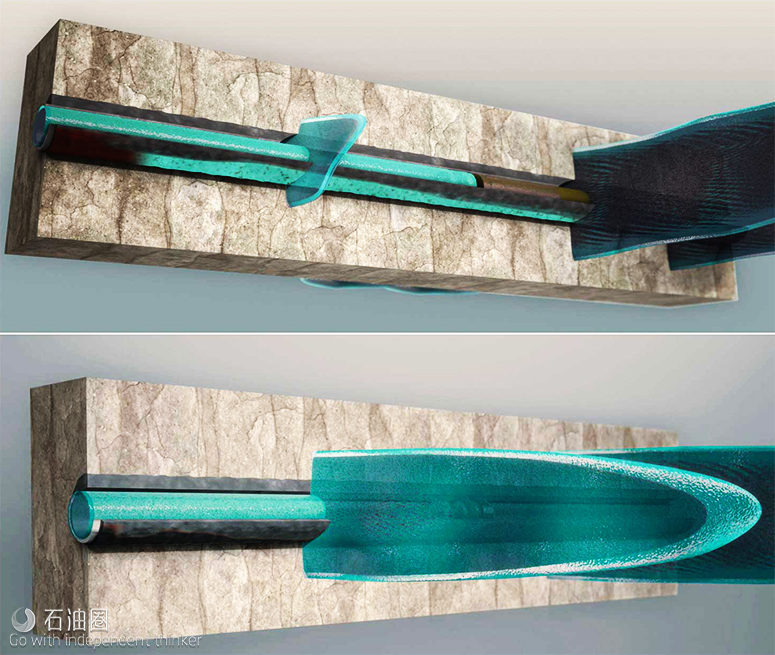

Improve fracturing efficiency by plugging drilling fluid channels

Conventionally during stimulation treatments, unintended channels behind the casing can act as nonproductive communication pathways between stages. Measurements taken in horizontal wells indicate that up to 30% of hydraulic fracturing stages communicate with neighboring stages during fracturing treatments. This allows stimulation fluids to reenter previously fractured stages, leading to overstimulation and other untreated and unproductive reservoir sections. Fulcrum cement-conveyed frac performance technology from Schlumberger is designed to improve hydraulic fracturing efficiency in cemented horizontal wells that are drilled with nonaqueous fluids (NAFs). Delivered during the cementing operation, Fulcrum technology helps keep fracturing fluid in the intended reservoir zone by limiting fluid migration through mud channels. The system is compatible with conventional cementing considerations, making it easy to use in the field. In addition, Fulcrum technology improves cement bond logs and ultrasonic logs for cement sheaths in the NAF environment.

Cloud-based hydraulic fracturing integrated software

NSI Technologies LLC’s new cloud-based version of the 3-D hydraulic fracturing design software, StimPlan, is a complete and integrated software for hydraulic fracture design, analysis and optimization, according to a press release. With a comprehensive integrated toolkit and the geometry models, StimPlan helps operators worldwide maximize their well performance while lowering expenditure and reducing their environmental footprint. Taking advantage of cloud-based parallel processing allows StimPlan to radically decrease the time required to run the multiple simulations required to achieve design optimization. nsitech.com

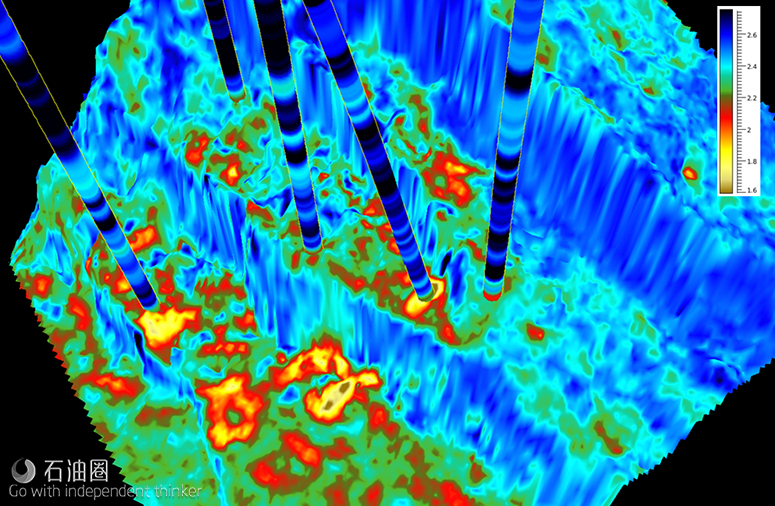

Software offers cloud-ready machine learning capabilities

CGG announced that GeoSoftware, part of its Geoscience Division, has released a new generation of cloud-ready reservoir characterization solutions. Jason 10.0, HampsonRussell 10.4 and PowerLog 10.0 also feature advanced machine learning capabilities and greater cross-product integration, improving E&P project performance and providing a better understanding of reservoir properties, a press release stated. The three new releases already run seamlessly on Microsoft Azure’s cloud environment and will soon be available on other major cloud platforms. HampsonRussell Emerge now delivers deep learning in the form of Deep Feed Forward Neural Networks for better prediction of reservoir properties. An open Python ecosystem in PowerLog enables the routine use of machine and deep learning in workflows to increase automation and achieve more accurate facies predictions. The new releases feature integration advancements, such as the ability to “load once, use everywhere” to streamline cross-product workflows as well as other user-driven improvements. HampsonRussell 10.4 updates advanced seismic conditioning to improve seismic data quality for better inversion outcomes, and amplitude-versus-offset modeling now offers a wider range of tools for investigating the seismic response of prestack data. Jason 10.0 makes it easy to design or vet facies classifications from petrophysical logs and immediately see the effects in the elastic inversion domain. It also has improved velocity calibration for time-to-depth conversion and depth inversion. PowerLog 10.0 advancements enable users to efficiently interpret groups of wells and apply machine learning to solve petrophysical challenges using the PowerLog Ecosystem.

Simulation training for advanced firefighting aims to enhance safety

Kongsberg Digital has released a new simulator system for training officers and crew in advanced firefighting. K-Sim Safety offers high-fidelity simulation covering all aspects of fire safety and reduces the impact of fire on board as well as plans strategies and tactics to control fire in various parts of the ship, enabling a safer and more effective response to incidents when they occur, according to a company press release. K-Sim Safety delivers practical exercises simulated in a realistic environment and meets standard industry regulations and requirements. K-Sim Safety is based on a detailed 3-D representation of a 152,000-dwt double hull Suez Max crude oil carrier with seven decks, which allows trainees to assess situations and determine the best response strategy, implement it and then observe the consequences of their decisions during a debriefing. Integration with K-Sim Engine and K-Sim Cargo simulators as well as K-Sim Navigation also offers the possibility for crew resource training where actions on one simulator will directly affect others. This approach engenders more focus on clear communication between different roles on board. As a full mission training system, K-Sim Safety includes two separate fire team muster stations with a detailed 3-D virtual hotel and machinery space application, visualized in an interactive 3-D walk-through animation of the entire engine room and four upper decks. It features high-quality object and equipment models combined with powerful incidental visuals including fire and smoke, flooding and missing persons to ensure a highly realistic scene.

Platform harnesses AI to transform oil trading analytics

Recently released OilX is a technology platform that aims to transform the oil trading industry through the application of artificial intelligence (AI), a press release stated. Established in 2018, OilX is a new cargo and flow tracking platform that provides users with a real-time view of the supply-demand balance globally. Through a joint venture between the maritime services organization The Signal Group and the OilX team, the platform aims to provide real-time and accurate oil analytics to empower traders and analysts to make better commercial decisions. In contrast with current, resource-heavy oil analysis, which is based on disparate and historical data, OilX aims to revolutionize oil analytics by harnessing AI to provide companies with a more accurate and timely view of market fluctuations, ultimately allowing companies to do more in less time.

New global UAV service for members

Oil Spill Response Ltd. (OSRL) has expanded its member offer with the launch of an unmanned aerial vehicle (UAV) service, a press release stated. The new service aims to enhance preparedness and response capabilities to better support members’ needs in the event of a spill. To facilitate the service on a global basis and to ensure the shortest time to mobilization, OSRL has signed call-off agreements with several third-party UAV providers around the world. Launch partners for the service include Bristow Aerial Solutions, Sky-Futures and Vertical Horizon Media. Each partner has been selected based on their relevant in-country experience, technical capabilities or geographical reach, and will ensure OSRL members have the most appropriate and effective solution to the specific challenge in hand, with the necessary flexibility to meet the broadest range of scenarios. The signed call-off agreements will provide OSRL members with pre-agreed rates, defined mobilization procedures and a standardized approach to managing common preparedness and response activity.

Hybrid panel for hazardous areas simplifies IIoT implementation

Emerson is changing the way companies are leveraging the Industrial Internet of Things (IIoT) to control power and data with the introduction of its Appleton PlexPower fiber panel, the world’s first hybrid panel board for hazardous locations, according to a company press release. This technology serves as a single point of control for both power and fiber communication cables to help users save up to 77% in installation, commissioning and maintenance costs. The Appleton PlexPower Fiber Panel centralizes control of electrical circuits and communication patch panels in one enclosure located in the hazardous areas, resulting in reduced cabling costs, increased power safety, greater configuration flexibility and a more reliable IIoT infrastructure, the release stated. The Appleton PlexPower fiber panel incorporates Belden MIPP fiber splice boxes that minimize installation time for fiber patching and enable hassle-free access during routine maintenance. It provides easy access for organizing and managing up to 12 straight tip connectors, subscriber connectors and lucent connector type fiber connections, making it ideal for use in a wide range of industrial networking applications requiring maximum system reliability and flexibility.

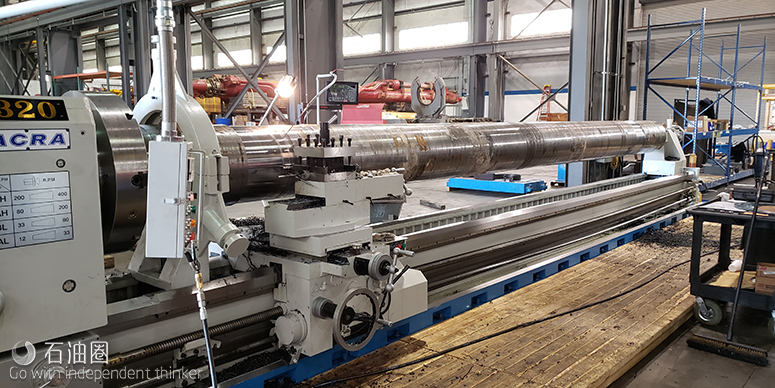

Company completes reduced bore direct acting tensioner project

Logan Industries, a hydraulic repair, manufacturing and rental company, has successfully completed a reduced bore direct acting tensioner (DAT) project to enable the use of the DAT in shallow water. The project required making an existing deepwater DAT suitable for shallow waters using the existing rod and barrel, external footprint and interface points, while maintaining the same pressure rating and tuning the operating characteristics from deep water to shallow water. Logan used a sub-arc welding machine and precision barrel positioners to manufacture the equivalent of reduced bore DAT barrels and inserted these barrels (which become reduced bore sleeves at this point) into the existing DAT to effectively reduce tensioning forces between the marine riser and subsea wellhead. This improved the operational performance of the DAT in shallow waters with lighter loads.

“We were able to save the client full replacement costs, while accommodating their existing interface points and control lines. We provided an option to the operator that wasn’t readily available and gave them a drop-in solution,” said Dean Carey, technical director for Logan. “Also, it gives them the ability to convert and unconvert when their water depths change for different well locations.”

The DAT conversions are set to ship to the customer this month.

石油圈

石油圈