Vx Omni:Subsea multiphase flowmeter

When wellheads or trees and production control equipment are located on the seabed, multiphase flow tests are more challenging. Surface measurements of production from subsea wells require the installation of costly subsea test lines, and platform-based facilities with topside test separators do not often have capacity for tying in subsea wells.

The Vx Omni* subsea multiphase flowmeter solves these challenges. This reduced-footprint, highly accurate multiphase flowmeter takes the application of flowmeter technology to 20,000 psi while expanding on capital efficiency, expediting lead times, and achieving unparalleled reliability.

Leveraging the accuracy and precision of Vx* multiphase well testing technology, the flowmeter addresses the need for real-time commingled process stream measurement at the well or manifold for use in well testing, production monitoring, and fiscal allocation.

Reduced lead time

The number of parts in the Vx Omni flowmeter has been reduced by approximately 66%, compared with previous-generation technologies. More than 90% of these components, including the most advanced instrumentation, are standardized for pressure rating, process fluids compatibility, temperatures, flow rates, and water depth.

Capital efficiency

The Vx Omni flowmeter offers new possibilities for obtaining data about gas, oil, and water flow from subsea development wells, including those in remote locations. The flowmeter can provide substantial cost savings through downscaling or eliminating surface well testing facilities and subsea test lines. Design simplification equates to fewer parts and less complexity, requiring the use of less material and fewer personnel hours.

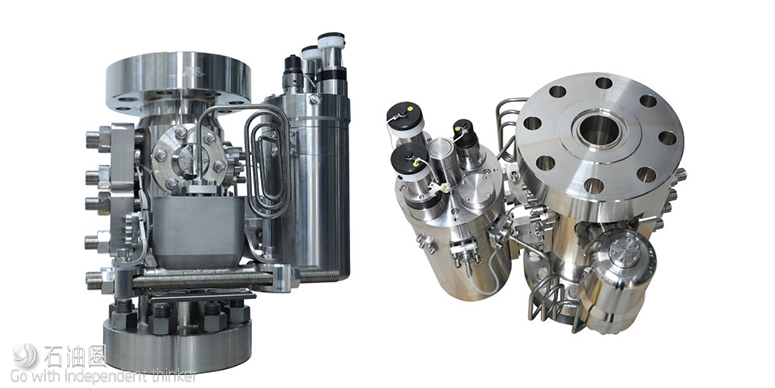

The Vx Omni flowmeter (side view at left, top view at right) takes subsea flowmeter application to 20,000 psi and features a reduced-footprint, simplified design.

Superior reliability

Redundancy, retrievable electronics, and condition monitoring are built into the Vx Omni flowmeter design, resulting in unparalleled dependability and availability. Reliability projection indicates that the flowmeter’s mean time between failure is 216 years.

Unparalleled metrological performance

The Vx Omni flowmeter is the only subsea multiphase flowmeter in the industry that measures in high frequency at a single point in the venturi throat, thereby avoiding cross correlation of measurements from multiple locations throughout the system. This technique ensures accurate and repeatable flow rate measurements in any multiphase flow regime and in production fluids ranging from heavy oil to wet gas.

APPLICATIONS

Subsea well testing

Continuous production monitoring

Fiscal allocation and custody transfer

Well performance evaluation

Production measurement for heavy oil to gas condensate

BENEFITS

Short lead time and reduced project costs

Unparalleled reliability (mean time between failure = 216 years), reducing lifetime ownership cost

Accurate, real-time flow rate measurements under unstable flow conditions to reduce uncertainty, improve decision making, and save costs

Increased recovery rates through

Improved understanding of well dynamics

Elimination of major pressure loss in production stream

Updated flow rates for reservoir monitoring and production forecasting

Precise allocation factor to reduce risk of allocation disputes

Remote metering operations for reduced operating cost from fewer offshore visits

FEATURES

Design standardized for the most stringent requirements, including 20,000 psi [137.9 MPa] and 14,750-ft [4,500-m] water depth

Ability to attain approval from Bureau of Safety and Environmental Enforcement

Qualification in accordance with API Specs 17D, 17F, and 17TR8

Fatigue evaluation based on Section VIII-2 fatigue curves and a typical load history

Redundant electronics as standard

Retrievable electronic canister option available

Dual-gamma spectroscopy

Repeatable, accurate measurements

Single-point measurement

Exceptional dynamic response

High-frequency measurement for detailed flow dynamics

No need for separation and flow calibration

No moving parts

For downward flow, gas flow rate uncertainties should be increased by 1%, and liquid flow rate uncertainties should be increased by 2%. Throat pressures greater than 20-bar absolute pressure. Differential pressure greater than 100 mbar. Repeatability and reproducibility of Vx technology is typically better than 1% for most measurements.

† 52-mm venturi size = 1.8 m3/h; 65-mm venturi size = 1.9 m3/h; 88-mm venturi size = 2.3 m3/h. In the GVF range of 90% to 98%, the largest of the absolute and relative uncertainties is applicable.

‡ For throat pressures greater than 35-bar absolute pressure.

§ For throat pressures greater than 25-bar absolute pressure.

†† At low GVF, the uncertainty is limited by an absolute value of 2 m3/h at line conditions.

‡‡ 0.05% can be achieved with 30-min logging time.

石油圈

石油圈