Digital Twin Solution:The Field of Tomorrow, Today

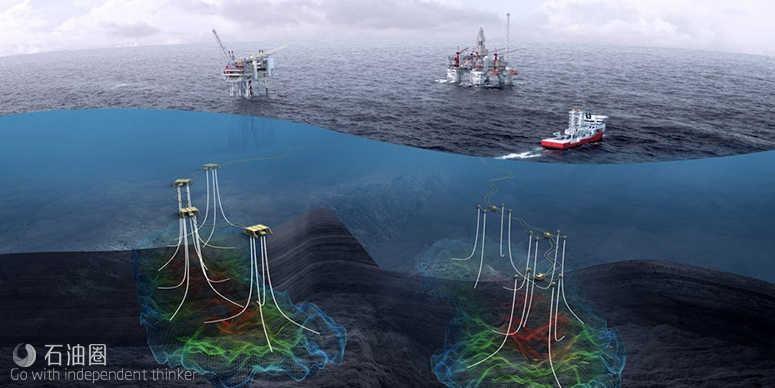

Across the entire life-cycle of a field, FieldTwin creates and maintains a digital twin — an exact digital copy of an oil and gas company’s physical assets — which enables producers to maximize asset performance and value.

Immediate digitalization opportunities create big value for oil and gas companies looking to capitalize efficiency and performance in low oil price markets. FieldTwin maximizes Big Data, Creates the Digital Twin, Transforms Field Operations.

What Is FieldTwin? Harnessing the Power of Your Data

Statistically, much of the data you have in your company lies under-utilized in databased and expert systems or is difficult to harness because of its size or file format.

The true digital twin of your offshore field planning, installation, and/or operations transforms your data into powerful capital for your success.

The digital FieldTwin is:

a single source of truth for all parties involved

integrates IoT sensor data for real-time monitoring of equipment statuses, well flow-rates, production values, vessel locations, and engineer tasks

streamlines previously unmanageable data streams through visual representation of equipment data

reduces operational time-lines

secures data through Cloud security systems

connects AI and historical data to well-planning, drilling, installation, and operations

Utilize the digital copy of your field in FieldTwin to digitize offshore field development, installation, production performance metrics, and equipment maintenance. This solution connects, predicts, supports, and monitors equipment maintenance, field operations, and well-production.

How It Works

Imagine a pre-FEED firm digitally designing and optimizing well-placements, field layouts, and early-stage installation schedules. The digital product is handed off to the engineering firm responsible for the FEED stage of that field’s development – all in a matter of weeks, as opposed to months or longer. This is what FieldTwin is achieving today. This same process would repeat again after the engineering is complete and installation begins.

Now, through FieldTwin, critical operation data is visually represented on specific assets as warnings or notifications when set parameters are exceeded. Our customers ate creating safer and more responsive operating conditions, lowering risks, and better preserving the longevity and integrity of field equipment. Additionally, offshore asset inspection, maintenance and repair programs become more effective as access to more robust information informs priorities, timing, and the expertise needed in planned maintenance.

FieldTwin makes data more secure by being a Cloud-based platform. The comprehensive security measures developed by Google, Microsoft and Amazon, are unbeatable. Operating within the secure Cloud also makes it easier to integrate data and break up the barriers built by legacy systems which impede data usage. A digital field twin enables data accessiblity and supports innovative ways to exploit this data, i.e. smarter drilling, greater field automation, and improved safety.

How You Benefit

Traditional “digitalization” approaches can threaten O&G companies’ long-term viability as they involve significant upfront CAPEX expenditures. Deploying IoT devices, SMART sensors, and robotic tools require expensive new equipment investments, employee training, and retrofitting of existing systems. Such investment may sound compelling but the ROI on such investment is difficult to assess.

FieldTwin is a more efficient and immediate digitalization strategy for oil and gas companies improving their operations with digital quickly. FieldTwin instantly implements data-driven solutions to improve work processes, increase data accessibility, and usability.

FutureOn is preeminent in the development of the digital field twin; FieldTwin is currently deployed operationally in real-world fields and early reports show that FieldTwin reduces pre-FEED field planning time and investment by at least 60%.

All stakeholders can now see more than ever before — the same information, at the same time. Subject matter experts can participate to bring their special knowledge into the flow early and often, to make more impact on a project’s outcome.

石油圈

石油圈