1.Tri-Strakes™ Lite

Pipelines unsupported over free spans, such as steel catenary risers and rigid steel flowlines, are prone to vortex induced vibration (VIV) fatigue, which can cause serious performance issues such as pipe girth weld failure or premature pipe malfunction.

Developed in response to market demand, the T-Strake is a high quality, cost-effective VIV suppression system manufactured by Trelleborg Offshore. The system consists of overlapping and interlocking moldings, with three-start helical strakes to provide an effective triangular or trapezoidal strake profile.

Working with polymers across a number of technologies and industries, Trelleborg Offshore was able to use insight and innovation to improve packing and handling factors using best-value engineered solutions. The innovative manufacturing process means that the T-Strake™ can be produced up to six times faster than systems manufactured using traditional techniques, ensuring shorter lead times.

To perform at every level, Trelleborg Offshore built up a wealth of in-house VIV knowledge through consultation with industry renowned hydrodynamicists, alongside computational analysis. Physical hydrodynamic testing combined with in-house impact, axial slip and load bearing capacity testing has produced a hydrodynamically efficient and load bearing capable product. All materials and geometries used are fully qualified for long term subsea use.

Each section of the system has been designed as a single, lightweight component, enabling quick and easy pre-install onshore or install offshore. The design permits the system to be stacked efficiently during shipping, ensuring more efficient and cost effective transportation and installation. Features: •Cost effective high density packaging •Light weight and easy to handle •J-Lay load bearing capacity •Temperature resistant up to 70 °C / 158 °F •Qualified geometry and materials •Quick installation •Available in a wide range of colors

Advantages

High temperature resistance

Temperature resistant up to 70°C/158°F

Quick and easy installation

Each section of the system has been designed as a single, lightweight component, enabling quick and easy pre-install onshore or install offshore. The design permits the system to be stacked efficiently during shipping which also reduces space taken up on the vessel.

Reduces marine growth build-up

Available with anti-foul coating or paint to design against marine growth build-up, particularly in shallow water environments.

2.Tri-Strake™ Stinger

Current flow around a pipeline can result in vibration due to vortex shedding. The frequency of this vibration can become close to the natural frequency of the pipe, which could cause catastrophic fatigue or damage the pipeline. Trelleborg Offshore offer PU VIV strakes to suppress Vortex Induced Vibration (VIV).

In deepwater riser applications where the use of steel catenary risers (SCRs) is common, these risers can be introduced to the phenomenon of Vortex Induced Vibration (VIV). This is caused by the regular shedding of vortices from the pipe when subjected to a steady current. The shedding of the vortices can “lock into” the resonant frequency of the pipe along a significant length and can cause the pipe to vibrate. VIV causes accelerated fatigue damage and can give rise to problems such as pipe girth weld failure or premature pipe failure. Other applications prone to VIV are rigid steel flowlines unsupported over free spans and major deepwater field developments requiring a large number of thermally insulated pipelines.

Trelleborg Offshore recognizes that this is an increasingly common problem and therefore, in order to suppress the damaging vibrations to an acceptable level, have put together a comprehensive design package which provides a successful VIV suppression system.

The VIV problem has been analyzed by Trelleborg Offshore using Computational Fluid Dynamics (CFD) software and physical tow tank testing. The results were used to verify the design of the strake concept. Once the suppression strakes are applied, the profile of the VIV strakes practically eliminates periodic vortex shedding from the risers and flowlines. Our VIV suppression strakes are manufactured to order and can accommodate any likely riser or flowline diameter.

PU VIV Suppression Strakes

PU VIV suppression strakes combine the benefits of traditional cable and flowline impact and abrasion protection with an effective VIV suppression profile. The product is manufactured in marine grade polyurethane (PU).

ROV Installable Strakes

Remotely Operated Vehicle (ROV) installable strake covers are high performance composite covers with an attachable polymer strake profile incorporating the field proven hinge and ratchet locking mechanism known as Remote Operated Ratchet (ROR) which allows the ROV to handle, open and securely close the covers around the pipeline. The covers are designed to be installed safely and efficiently in water depths to suit the deepest rated ROVs.

Integral Strakes

Trelleborg Offshore is able to mould strake profiles into many of its products during manufacture. This is ideally suited for thermal insulation shells, where a strake can be molded in, to provide effective VIV suppression.

Load bearing capability

PU VIV suppression strakes can accommodate high installation loads encountered during S-lay or J-lay. Strake design can be of a triangular of trapezoidal profile to offer varying degrees of flexibility during installation.

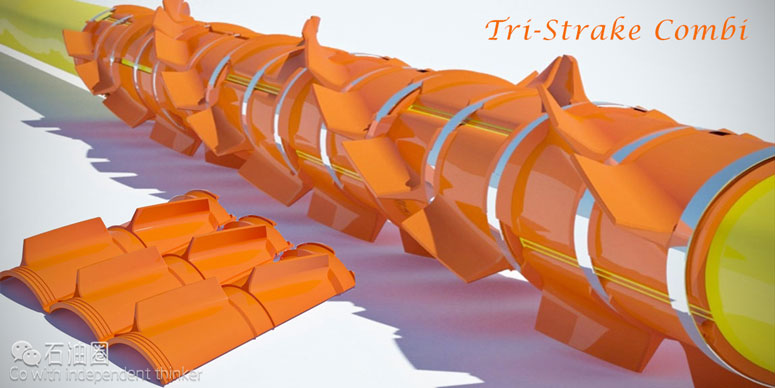

3.Tri-Strakes Combi

Trelleborg’s offshore operation has launched a new vortex induced vibration (VIV) suppression system. The Tri-Strake Combi, developed to complement the high performance S-Lay capable Tri-Strake Stinger system and the cost effective Tri-Strake Lite system, not only eases installation but provides added resilience and load-bearing capacity, including stinger installation loads.

Jonathan Fox, senior product development engineer for Trelleborg’s offshore operation, said: “To combat this, the Tri-Strake Combi comprises interlocking moldings, with three-start helical strakes.”

Trelleborg utilized its offshore and VIV knowledge in the design of the Tri-Strake Combi and carried out extensive computational analysis and physical testing. The system’s lightweight construction provides operators with a simple and rapid assembly method. While the customized, high-endurance material selected for the system not only provides added resilience and load-bearing capacity, it also eases installation.

Each section of the system has been designed as a lightweight hinged component, ensuring it is quick and easy to pre-install onshore or install offshore. The unique, modular design enables the system to be stacked during shipping, ensuring more efficient and cost-effective transportation.

“The Tri-Strake Combi was developed in response to market demand for a high quality, cost-effective VIV suppression solution. Using an established manufacturing technique, we were able to meet these demands by using rapid manufacture leading to quick installation times and reduced transportation costs.” Fox added.

Advantages

High temperature resistance

Temperature resistant up to 60°C/ 140°F

Quick and easy installation

Each section of the system has been designed as a single, lightweight component, enabling quick and easy pre-install onshore or install offshore. The design permits the system to be stacked efficiently during shipping, which also reduces space taken up on the vessel.

Reduces marine growth build-up

Available with anti-foul coating or paint to design against marine growth build up, particularly in shallow water environments.

About Trelleborg Offshore

Trelleborg is a world leader in engineered polymer solutions that seal, damp and protect critical applications in demanding environments. Its innovative engineered solutions accelerate performance for customers in a sustainable way. Using advanced polymer material technology, Trelleborg Offshore provides high integrity solutions for the harshest offshore environments. Trelleborg Offshore specializes in the development and production of polymers and syntactic foam, for all levels of the Offshore industry.

石油圈

石油圈