A new monitoring service locates microseismic and strain events in real time.

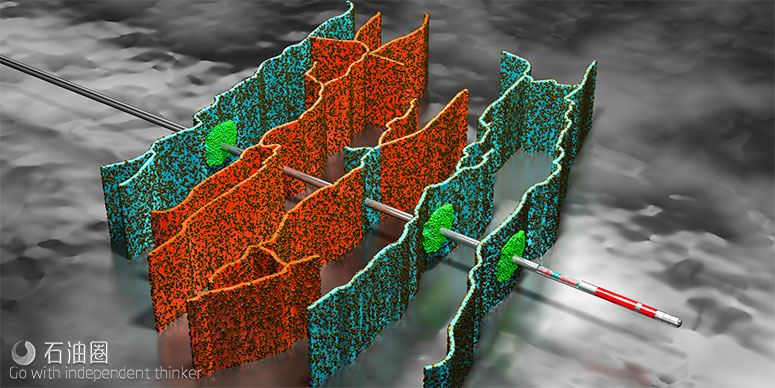

While shale oil and gas production continues to captivate the global energy market’s attention, operators have their focus on optimized production. To improve stimulation and completion designs and deal with the growing concern of interwell communications, operators need data to gain insight into reservoirs. Evaluating stimulation performance in real time and quantitatively measuring the extent of fractures are the biggest challenges in shale play development.

Conventional technologies, such as tiltmeters, microseismic geophone arrays, chemical tracers

and pressure sensors, only provide restricted information—mostly due to their limited coverage.?Distributed acoustic sensor (DAS) systems and temperature sensors have been successfully used for monitoring hydraulic fracture operations. However, the complexity and costs associated with permanent fiber-optic installations would limit the number of wells that could be fully evaluated.

High-resolution DAS

To overcome these challenges, Silixa has released Carina XwellXpress, the crosswell low-frequency strain and microseismic monitoring service that locates microseismic and strain events in real time using wireline conveyed measurements, allowing operators to improve stimulation and completion designs on the fly. This service removes the most challenging barriers that keep operators from implementing diagnostic services: high costs, lack of real-time data and interference with operations.

The service capitalizes on the performance of the company’s DAS, Carina, that has a 100x improvement in signal-to-noise ratio (S/N) and greater than 100x improvement in the lower frequency ranges of slow strain and microseismic compared to other DAS systems. As a result of the system’s sensitivity, it can detect changes in low-frequency strain induced by the development of the fracture network while simultaneously detecting microseismic events and crosswell frac hits. The system gathers data on a new generation of engineered fiber-optic cable called Constellation.

Real-time frac monitoring

The measurement of crosswell strain and, specifically, the poroelastic effect of rock mechanics or strain have not been measured to date with a wireline intervention cable. For the first time, this new service allows the monitoring of the entire wellbore in real time, enabling the visualization of effects modeled and understood but not measured.

The measurable noise of a DAS with engineered fiber is 100x (20 dB) lower compared to that when using standard fiber. In addition, the DAS performance is comparable to that of geophones around 10 Hz but can far exceed the response of geophones in the range below 1 Hz. The highly sensitive low-frequency strain measurement provides valuable data for monitoring the crosswell poroelastic buildup within the reservoir and the detection of frac hits in the offset well.

The intervention cable can be deployed into any well not being treated at the time, turning it into an observation well. Wells can be chosen during the hydraulic fracturing operation to map crosswell strain, locate microseismic events and collect key seismic data leading to a better understanding of completion design and effectiveness of the actual fracture geometry as pumped.

Fiber field deployment

A fiber field deployment was set up in unconventional multiple wells. Two of the wells were installed with a permanent engineered fiber cable cemented behind the casing. However, it was recognized that acquiring additional data between the wells can be valuable in understanding the crosswell interference. This was achieved through the use of a new engineered intervention wireline cable pumped down into an already completed well. The wireline cable also has a monoconductor for being tractored downhole and/or monitoring collars during the pump down.

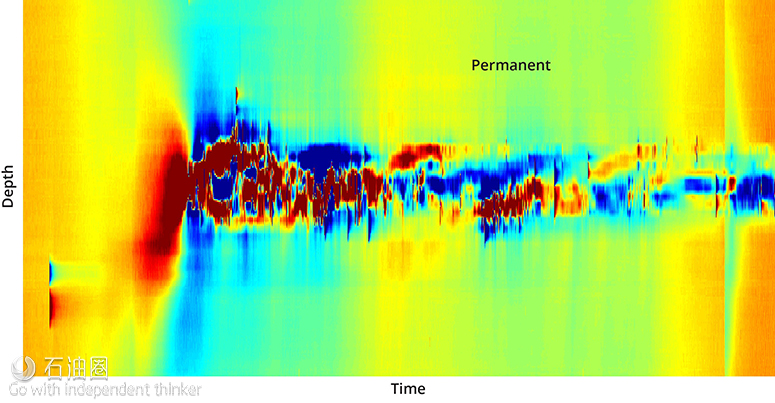

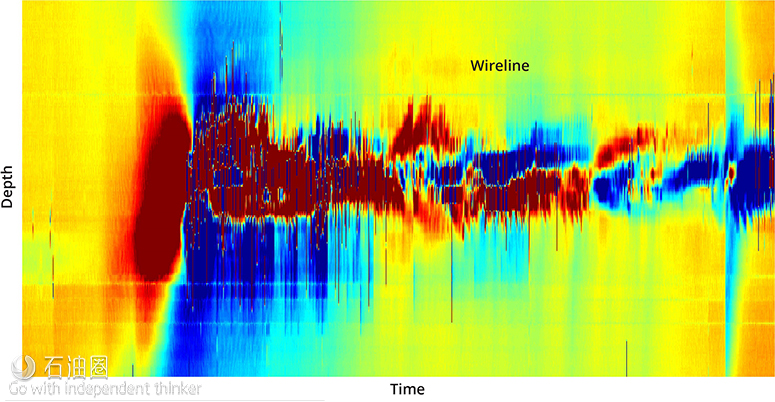

The data recorded both on permanent and intervention cables were fed into the completion design in nearreal time to optimize the operations on the current well pad and for future development plans.

Crosswell strain monitoring and frac hits characterization

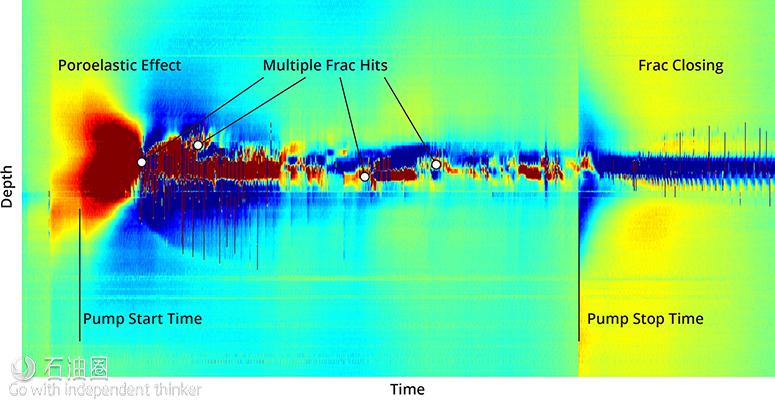

The crosswell strain data (Figure 1) was acquired on the wireline. Critical strain effects and treatment processes, including pump start time, poroelastic effect, frac hits, pump stop time and fracture closure can be seen with clarity. These new data allow completion engineers to map the depth, azimuth and speed of the fractures and feed that information back into the fracture models to validate and optimize the designs for the next operation.

To further validate the intervention response, the wireline cable was pumped down in the same well that has been instrumented with a permanent fiber behind the casing. A strong similarity can be observed in the response of both cables.

Multiple frac hits can be observed following the tensional and compressional strain building up due?to the poroelastic effects as the fluid is pumped into the reservoir.

Microseismic

The objective in hydraulic fracture monitoring is to map the treated volume’s height, length, width and azimuth. A DAS enables the realization of new monitoring applications where the fiber-optic cable can be readily deployed as a dense, wide aperture acoustic phase-array in novel configurations. With recent advances, it is possible to collect data comparable to geophones across the entire wellbore simultaneously. Additionally, a fiber-optic array in two or more wells requires only arrival times for hypocenter determination, without the need for polarization modeling and measurements. Both P wave and S-wave arrivals from a microseismic event can be seen over the entire cable length. With the sensitivity of the measurement, events can be seen in the vertical section as well as the horizontal, allowing better location by taking into account the wellbore trajectory.

Time-lapse VSP

An important aspect of time-lapse vertical seismic profiling (VSP) is the effort to characterize the changes in the reservoir from the frac operations and reservoir depletion. In this case, Silixa recorded changes during frac activities with VSP data acquired after each frac stage. The effectiveness of the frac design and the return on investment for the pad can be continuously improved by using this technology.

The increased S/N allows quality acquisition with fewer sweeps. The ability to establish baseline data that can be compared to post-frac and post-production sweeps allows the continuous improvement of the frac process. Improvements in DAS measurements utilizing the engineered fiber means that it is possible to collect high-quality VSP data in between stages without interfering with the overall operations.

In addition, high-quality microseismic events can be correlated with 4-D VSP effects to help understand fracture complexity.

Conclusion

The next generation of a DAS system utilizing the engineered fiber offers 100x improvement in sensitivity compared to standard fiber and provides unprecedented data quality both on permanent and wireline intervention cables.

The intervention wireline cable can be economically deployed for crosswell strain identification on frac hits, microseismic monitoring and time-lapse VSP acquisition. The wireline data can be combined with the permanently installed fibers to provide a wide volume coverage for fracture monitoring and completion diagnostics.

Feeding in the combined near-real-time datasets into the completion workflow, a better understanding of the key operational decisions can be gained to optimize the completion process with a high level of confidence. These measurements lead to better frac design, sequencing decisions and better ultimate oil recovery from the reservoir.

石油圈

石油圈