Eliminating the need for costly equipment or hazardous manual handling, Coretrax has seen the deployment of its drill pipe cleaning tool, the CX-Ball, bypass more than 2,000 sales within five years, saving more than 11 days of rig-time cost and risk.

Based on an average time saving of eight minutes per ball, this in total has saved 278 hours of rig-time, equivalent to 11.58 days since the product was launched in 2014. In one North Sea campaign, it has been used consistently for the last 74 well abandonments saving 57.6 hours of rig time alone.

“The CX-Ball essentially embodies the concept of marginal gains,” John Fraser, Global Business Development Director with Coretrax, said. “The simplicity of the tool allows easy and quick deployment and reduced time in the “red zone”. While this doesn’t initially suggest big time savings, over multiple applications in a campaign, significant financial, safety and rig-time savings can be achieved.”

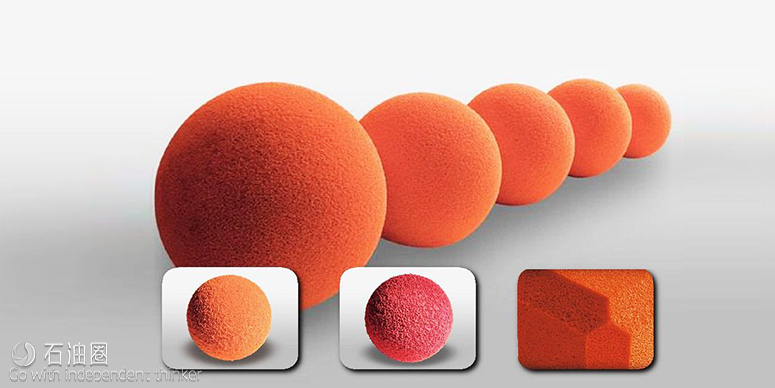

After a cement job, foam wiper balls are used to avoid potential residual cement, fluids or debris, setting and building up on the internal diameter (ID) of the pipe. However, competently loading the large foam balls into the restrictive tool joint is challenging and can involve the use of expensive equipment and the safety risks associated with manual handling and machinery.

Unlike other products on the market, the CX-Ball is encased in a soluble material which temporarily restricts the shape of the ball. This allows it to be easily and accurately deployed by a launch tube directly into the drill pipe. When the CX-Ball comes into contact with water, the ball expands and returns to its original shape. The high parting stretch ratio of the foam ball allows it to pass through small restrictions undamaged as it is pumped downhole.

CX-Ball

Following cementing operations residual cement, drilling fluid or debris is often found in the drill pipe or tubing. This can present a risk of contamination during future cement jobs and if left in the bore of the drill pipe it can result in corrosion and permanent damage of the drill pipe. Conventionally a foam wiper ball is used to clean the internal diameters of the drill pipe or tubing however loading the large OD foam wiper ball into the drill pipe at surface can be a difficult and time consuming task.

The Coretrax CX-Ball provides a simple solution with the CX-Ball launchers arriving offshore, pre-loaded and ready to use. To launch the CX-Ball simply remove the cap, place the launcher in the box connection of the drill pipe and compress the plunger to release the ball. The standard Coretrax foam wiper balls are made of natural rubber with a high parting stretch allowing them to pass intact through small restrictions. These balls are compressed and wrapped in a soluble film before being loaded into the recyclable launchers. Within a minute of deployment the soluble film dissolves allowing the foam wiper ball to expand to its original form effectively wiping the ID as it is pumped down the drill pipe.

The use of the CX-Ball significantly reduces the deployment time associated with loading foam wiper balls and can present time savings in excess of 10 minutes per application, simultaneously reducing the exposure of the rig crew to any OBM or hazardous drilling fluids present in the drill string.

Highlights:

- Quick to deploy and easy to use

- Minimises personnel exposure to potentially harmful well fluids

- Minimises personnel exposure to the “Red Zone”

- Time Savings: To date Coretrax have sold 832 CX-Balls and, based on an average time saving of 8 minutes per ball, have subsequently delivered 111 hours of rig time savings to the operator.

石油圈

石油圈