A major Middle East operator has recovered from stuck pipe by severing its drill string in just one hour, reports Churchill Drilling Tools. It’s the third time this year that the company’s dart-activated HyPR HoleSaver technology has been successfully deployed in the Middle East.

To recover from a previous stuck-pipe incident in the same well, the UAE-based operator contracted high energy source cutting services. However, the additional equipment, personnel and logistics cost two days of rig time. So, when the operator became “differentially stuck” in the same well at 12,785 ft on 28 May due to heavy losses, the team were ready with the HyPR HoleSaver to sever, plug and abandon the section much more quickly. The system requires no additional topside equipment or personnel.

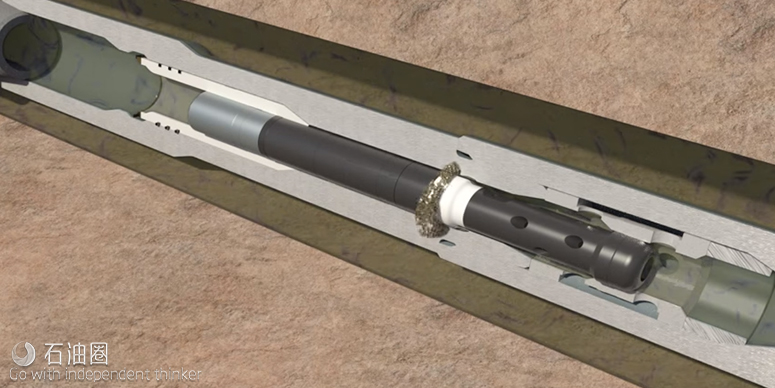

To provide the optimum circulation parameters, the operator first activated Churchill’s DAV MX CircSub, which had been placed beneath the HyPR sub in the drillstring. The HyPR HoleSaver dart was subsequently dropped and pumped to redirect the flow of mud creating a high velocity stream of fluid, using the existing mud system, to erode and sever the string.

The operator witnessed the expected drop in circulating pressure over a period of 45 min of pumping at 520 gal/min. Satisfied that enough progress had been made, applying torque and overpull parted the string with ease. On previous HyPR severs, operators have cut through around 90% of the HyPR sub’s full strength inner connection before applying torque to twist-off, generally taking two to three hours. However, on this occasion the operator applied torque much earlier to save the extra time. In total, the process took just an hour, a record for Churchill, and widely thought to be the industry’s quickest planned severance from stuck pipe. The operator subsequently plugged and abandoned the section and moved operations to another well.

Working in partnership with the operator, the Churchill team optimized the tools’ configuration and supported the client to get out of hole quickly and safely. The drilling manager was pleased with the performance of both the DAV MX CircSub and the HyPR HoleSaver.

“The ability to recover safely from a stuck-pipe event in just an hour, as our UAE-based clients proved last month, is a landmark achievement for the sector,” Nicholas Kjaer, General Manager of Churchill’s operations in the Middle East and Asia, said.

“As the industry leaders across downhole circulation, demand for our HyPR HoleSaver technology continues to increase as operators recognize the significant savings it delivers.”

The HyPR™ HoleSaver™ is the world’s first hydraulic pipe recovery system.

Using ordinary drilling mud for circulation and pumped through a highly powerful HyPR™ jetting dart, full strength subs are cut in just a few hours. The tool, which should be run above our DAV MX™ CircSub, gives the user a truly low cost and rapid way to insure against most stuck pipe situations.

Hydraulic darts are simple to use, completely safe and therefore can deliver a much faster recovery.

The Smart Choice:

- Cost saver – eliminates the need for wireline crews and reduces third party mobilisation.

- Fast – no additional equipment or personnel required, commence fishing or cementing and side-track operations almost immediately.

- Simple – user operated.

- Safe – no explosives or other high energy sources.

- Ability to run multiples in one string.

When attempting to fish the BHA is preferred, this dart leaves a clear unrestricted access to the fish after it has cut the string free. An interference added to its tail means that as the cut pipe is withdrawn it collects the fishing dart and carries it back to surface.

- Ceramic Diverter Jet

- Leaves a clear fish

- Fishable

石油圈

石油圈