Drilling automation has been a topic of great interest to the oil and gas industry for the past several years, but uptake has been limited due to volatility in the marketplace and a cultural resistance to such massive change. In a landmark project on the North Slope, however, BP Alaska recognized the potential impact of new technology to drive a step change if properly implemented, embracing innovation and moving forward with closed-loop drilling automation. This included deploying our NOVOS™ platform, downhole drilling dynamics tools, drilling apps, and wired drill pipe as part of a full automation technology package on Parker Drilling’s Arctic Alaska Drilling Unit (AADU), Rig 272.

On this project, automation was prevalent except for pipe-handling while in slips (i.e., torqueing and untorqueing connections), tripping, and BHA makeup and breakdown. The drilling automation system enabled BP Alaska to not only rise above the drilling-speed-focused automation business model of the downturn, which prioritized ROP, but also to obtain performance improvements across categories. BP Alaska saved approximately 4 min. per intermediate hole-section connection and 2 min. per production hole-section connection, when compared with relevant offsets, by using NOVOS. Wired drill pipe saved time on both surveys and downlinks, including the effective elimination of all flat time and invisible lost time related to downlinking. Finally, reductions in downhole dysfunctions and improvements in ROP were made possible by the drilling apps, which were integrated into NOVOS.

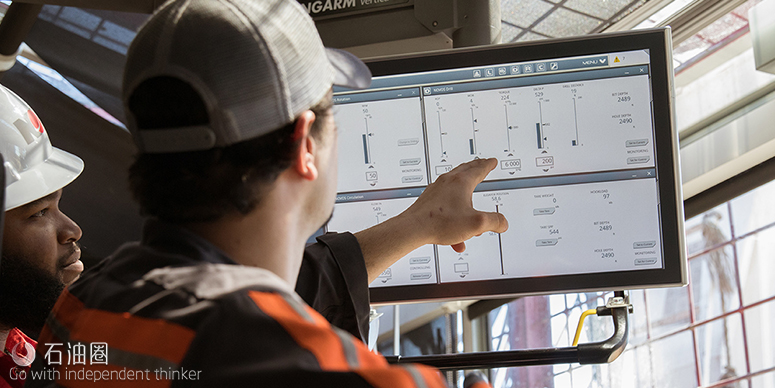

WHAT IS NOVOS?

We provide the technical expertise, advanced equipment and operational support our customers in the oil and gas industry need to succeed. We have the people, capabilities and vision to serve the needs of a challenging and evolving industry.

The driller oversees the process and can easily take control if desired.

NOVOS™ is the industry’s only reflexive drilling system, automating repetitive drilling activities, benefiting contractors by allowing drillers to focus on consistent process execution and safety, and benefiting operators by optimizing drilling programs.

What Is a “Reflexive Drilling System”?

A reflexive drilling system is designed to perform a series of actions when prompted, just as human reflex respond when acted upon by a specific stimulus. The NOVOS™ reflexive drilling system is easily scalable and can augment existing people and processes for greater control, consistency and enhanced performance, or expand all the way to full closed-loop automation.

NOVOS CORE APPS

Drill to Plan

Uses the pre-loaded well plan as a target and drills down the same way every time.

Rotation

Manually adjust rotation and automatic oscillation of the top drive based on degrees or wraps. Drillers can also configure on-bottom and off-bottom RPM so that NOVOS automatically reduces rotation ever time the bit is off bottom. Other apps can also replace this rotation app to automatically control RPM.

Circulation

Manually adjust flow rate. Driller can also configure on-bottom and off-bottom flow so that NOVOS automatically reduces flow every time the bit is off bottom.

Tag Bottom

User can configure how NOVOS lowers the drill bit into the formation. User can configure drawworks velocity, ROP, and any parameters used for finding the bottom of the hole. NOVOS will automatically look for stable weight before ramping off-bottom RPM to on-bottom RPM.

Rig Config

User can configure how each tool operates. For example, how fast or slow mud pumps ramp, how fast or slow drawworks lowers and hoists, etc.

Friction Test

NOVOS will automatically run through the process of gathering pickup and slackoff weights as well as off-bottom rotating weight and torque. NOVOS will capture these values at the exact same distance every time and these values can be used for torque and drag purposes.

NOVOS Advantages

NOVOS™ provides control and consistency for any operation. It allows drillers to automate repetitive drilling activities, such as making a connection (offshore), coming off and on bottom, with specific parameters for circulation, weight-on-bit and more. The result is greater consistency, with every driller — regardless of individual experience level — able to achieve the same improved performance time and time again.

Precise Control

Set the exact parameters to meet the needs of your drilling program, from circulation to weight-on-bit and everything in between, and the NOVOS system performs at the push of a button.

Unmatched Consistency

Regardless of who’s at the controls, the NOVOS™ system offers the same performance, again and again, eliminating NPT and protecting your equipment.

Increased Performance

With more consistency comes greater performance. Because the reflexive system automates repetitive tasks, you’ll achieve better average performance throughout the entire drilling lifecycle, regardless of the experience level of the driller.

Infinite Customization

With additional off-the-shelf apps that can be tailored to your needs or completely custom designs, the NOVOS™ system can be updated to meet specific needs with just a bit of software.

Minimal Interruption

The whole system can be installed in 12 hours and requires limited additional hardware.

石油圈

石油圈