Enpro Subsea and DASS Can-K Pumps Inc. today announced a Memorandum of Understanding (MoU), which will leverage each company’s expertise to deliver multi-phase pumping solutions for topside and subsea well boosting.

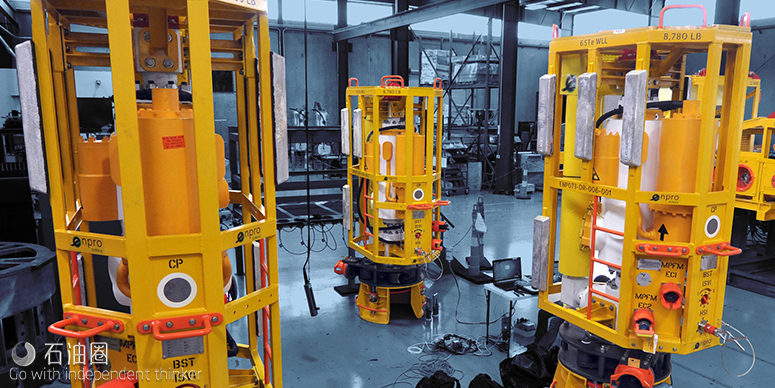

The announcement sees Can-K’s patented Electro Submersible Twin-Screw Multi-phase (ESTSP) pump technology being combined with Enpro’s subsea systems expertise and patented Flow Access Modules (FAM) technology to create a retrievable subsea pumping solution targeted primarily at individual wells.

The agreement will allow both companies to collaborate to provide targeted solutions globally for subsea and topside applications offering a low cost, low risk method of integrating Can-K pumps within new and existing subsea infrastructure.

FAM essentially creates an enhanced production ‘USB port’ within the jumper and flowline envelope. This supports the use of standard subsea Xmas trees and manifolds, with the FAM providing life of field flexibility within the system design. Pumping is one of a range of production enhancing technologies that FAM enables. These include metering, sampling, digital data acquisition and hydraulic intervention.

Enpro Subsea CEO, Ian Donald said: “We’re delighted to be working with Can-K. These innovative twin screw multi-phase pumps are used successfully in downhole and topside applications and the technology lends itself to single or small cluster well applications. Combined with FAM, the system provides a differentiated boosting strategy for our clients by enabling a cost-effective simplified infrastructure and efficient redeployment from well to well to deliver maximum ultimate recovery from subsea assets.”

Pradeep Dass, president and CTO of DASS Can-K Pumps said: “Twin Screw Pumps have been used in the oil and gas industry for more than 75 years with incremental improvement. Our proven ESTSP multi-phase pump represents a step change both in terms of performance and reliability. We’re looking forward to working with Enpro Subsea to bring these advantages to the subsea sector

The ESTSP (Electric Submersible Twin Screw Pump)-Multiphase is expected to replace 15 to 20% of ESP, Gas Lift and Sucker Rod Pumps in the world in the next 7 years. ESTSP is installed exactly like an ESP and it is operator-proof. Major savings in OPEX.

The Surface Twin Screw Multiphase Pump has entered the market as a Pipe Line Multiphase Pump (PMP) to replace all surface Multiphase Pumps using a patented technology.

ESTSP (Electric Submersible Twin Screw Pumps)-Multiphase, is a Paradigm change in Artificial Lift Technology

- Move all fluid up the tubing including all gas complete. True Multiphase Pump. – OPEX savings

- Isolate casings if required. Throw away gas lines from the casing to pull out gas. Use inexpensive casings for new wells in high H2S wells. -OPEX and CAPEX savings

- By moving all gas up the tubing you will reduce head requirement (lower fluid density), increase life of the motor, and have more hp to move fluid. – OPEX and CAPEX savings

- You don’t need any surface multiphase pump as you can use the ESTSP to move the complete fluid all the way to the battery as the ESTSP is a Multiphase Pump. Handle Gas in a compressed state downhole without any separation. – OPEX and CAPEX savings

- Reduce foot print on offshore platform.

- You will see the motor will cool faster and temperature rise is minimal even with high gas due to “dew point effect” that happens when you move fluid up the tubing swiftly. – OPEX and CAPEX savings

- Use one model pump for the entire life of the well and the field in some cases until abandonment. – OPEX savings

- It has the least shear compared to any other pump so it has very little emulsion. Save on de-emulsifiers. – OPEX savings

- Asphaltene will not break out easily due to very low shear.

- Control the pump with one parameter and that is the speed. Though unheard of in the ESP industry it is common to run from 25 to 90 HZ. The pump is balanced and all the thrust is shared between two shafts within the pump increasing life of the pump. No buckling of shafts.

- Use it for heavy oil, light oil and high gas. Multiphase.

- There is no need to do any throttling. There is no BEP. There is NO up or down thrust.

- It is installed exactly like an ESP. There is nothing new to learn. Just install, set it to low torque and high torque and walk away. All existing accessories of ESP can be used for ESTSP.

- Draw down to 0 psig or to vacuum at Intake. No other artificial lift can sustain such a performance.

Enpro’s patented Flow Access Module (FAM) enables maximum ultimate recovery from subsea wells.

FAM creates an enhanced production ‘USB port’ within the jumper envelope, enabling the use of standard Xmas Trees and Manifolds, with the FAM providing life of field flexibility within the system design…

Delivering ‘Smart Standardization’ and ability to fast track field development and deliver first oil faster.

Flow Access Module technology fully aligns with the industry driven strategic approach to fast track, capital efficient subsea tiebacks.

FAM enables a range of enhanced production options including metering, flow assurance, data acquisition, hydraulic intervention and fluid sampling, allowing the Operator to adapt the technology within the FAM to suit the needs of the reservoir.

- Differentiated subsea field development solution

- Faster, lower cost tiebacks, delivering early first oil

- Enhance functionality of Stock/Standard hardware

- USB for technology deployment independent of OEM

- Future Proof, provides Life of Field flexibility

- Minimise XT footprint for drill rig flexibility

石油圈

石油圈