Nissan Chemical America Corporation (NCA) introduces enhanced flowback technology (EFT) to complement its existing line of nanoActiv products. nanoActiv EFT is a nanoparticle micellar dispersion, employing a synergistic combination of a soybean extract solvent, a blend of surfactants and, NCA’s proprietary, patent-pending surface-modified silicon dioxide nanoparticles.

“One of the big challenges with hydraulic fracturing is that fracturing fluid filtrate can get trapped into the pore spaces in unconventional reservoirs causing a decrease in hydrocarbon mobility,” explains NCA President, William L. Smith.

nanoActiv EFT improves stimulation fluid interaction near the created and propped fracture faces and throughout the entire propped fracture network — increasing initial oil and gas production. It also delivers the unique advantages of fragmentation and reduction in interfacial tension.

“The presence of Nissan Chemical’s supercharged nanoparticles in nanoActiv EFT significantly increases the efficiency of the technology by contacting more surface area with a Brownian-motion, diffusion-driven mechanism known as disjoining pressure,” says NCA senior petroleum engineer, Yusra Ahmad.

Nissan Chemical’s nanoActiv EFT joins the existing nanoActiv® product line to deliver significantly more efficient and complete flowback of the fracturing fluids in a shorter period of time. nanoActiv products demonstrate Nissan Chemical’s commitment to supplying productive and innovative treatment fluids to the oil and gas industry.

Enhanced Flowback Technology (EFT)

nanoActiv® EFT increases profits through greater initial oil and gas production. It is a nanoparticle micellar dispersion, which uses a synergistic combination of silicon dioxide nanoparticles, a soybean extract solvent, and a blend of surfactants. nanoActiv® EFT exhibits an extremely effective primary chemical action, enhanced with the added mechanical properties of nanotechnology. nanoActiv® EFT delivers the unique advantages of diffusion, disjoining pressure, fragmentation, and reduction in interfacial tension. It improves stimulation fluid interaction near the created and propped fracture faces, and throughout the entire propped fracture network—increasing initial oil and gas production.

The Challenge

Hydraulic fracturing can introduce a variety of fracturing fluid systems into unconventional reservoirs. When a lower salinity fracturing fluid comes into contact with a higher salinity low permeability formation, fracturing fluid filtrate can get trapped into the pore spaces due to a difference in osmotic potential. This can lead to an increase in the water saturation and a problematic decrease in hydrocarbon mobility in pore spaces.

The Solution

nanoActiv® EFT effectively displaces hydrocarbons by reducing the interfacial tension of the fracturing fluid and mobilizing immobile water-block zones in pore spaces. The presence of nanoparticles in nanoActiv® EFT significantly increases the efficiency of the technology by contacting more surface area with a Brownian-motion, diffusion-driven mechanism known as disjoining pressure. The nanoparticles in nanoActiv® EFT fragment hydrocarbons into smaller droplets, allowing efficient recovery of fluids pumped and onset of rapid production. It cleans up residual fracturing fluid components such as residual gel and maintains maximum flow capacity of the proppant pack. nanoActiv® EFT also provides non-emulsion benefits to the fracturing fluid—eliminating the need for additional additives.

Application

nanoActiv® EFT is designed to be pumped in the body of the fracturing fluid as an additive at concentrations between 2 gallons and 10 gallons per 1,000 gallons of fracturing fluid. This allows nanoActiv® EFT to aid in a more efficient and complete flowback of the fracturing fluid—radically increasing the percentage flowback over a shorter time period.

The Amott Cell test is used for the determination of oil recovery based on the spontaneous imbibition of oil into a core plug followed by extraction of oil out of the core using the formulation to be screened. The data shows the results of Amott Cell testing performed in Boise Sandstones cores. nanoActiv® EFT outperformed the leading microemulsion technology by 20%.

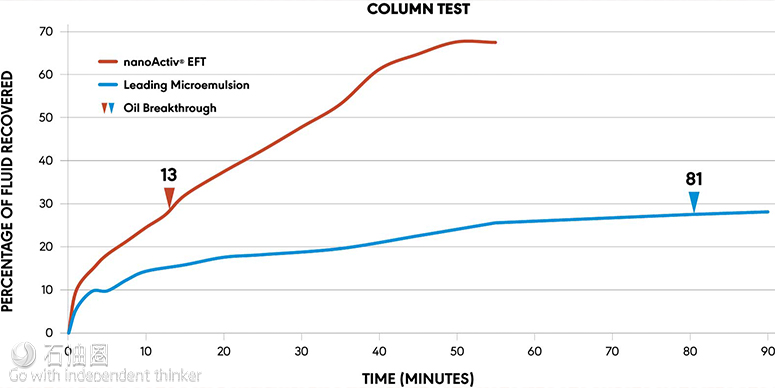

The column flow test determines the performance of an additive by measuring percentage fluid recovery and the time for oil breakthrough through a packed column. The column can incorporate a shale mixture, formation water, formation crude oil, and the additive provided for screening. In the plot above, two columns containing Mancos shale were treated with nanoActiv® EFT vs. the leading microemulsion technology. Results confirmed that oil breakthrough occurred significantly faster than that for the leading microemulsion technology, and at the 55 minute mark, nanoActiv® EFT produced 42% more fluid.

石油圈

石油圈