With its attractive project economics, development cycles and resource availability, shale has celebrated a boom over the last few years. It has been particularly critical as producers have tried to counter some of the deleterious effects of the industry downturn.

However, certain challenging, labor-intensive aspects of shale development continue to plague producers. This includes the flowback process, which involves cleaning up pumped sand from initial production after hydraulic fracturing has taken place. It typically requires constant manual intervention, with critical data captured from field instrumentation keyed laboriously into various data collection systems.

TechnipFMC’s new automated well testing (AWT) package is set to transform this inefficient and at times wasteful process by leveraging a set of digital solutions that includes our lightweight control and automation platform UCOS and a cloud-based data monitoring and advanced analytics platform.

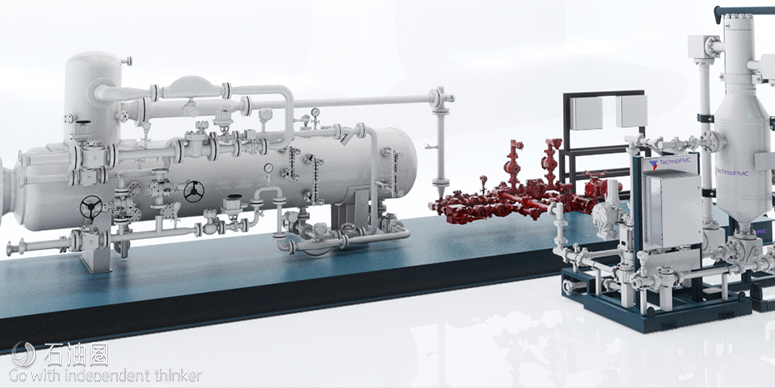

The pioneering solution arrives already assembled, with the separator and choke manifold fully connected and equipped with the latest technologies in controls, automation, sensors and data communications to ensure the highest level of workforce productivity and job performance.

The AWT is equipped with a fully automated package that provides readings of all process variables, valve positions and oil sampling averaging while streaming more than 1,000 different data points in near real time to our cloud-based advanced analytics platform. This web platform gives both the client and internal personnel access to real-time job performance information, asset health information, historical trending, comparative analysis, real-time SMS or email alerts and automated reporting tools.

“The AWT brings in a much higher level of automation,” says Hernan Anzola, vice president, Surface Products. “It allows us to operate with less personnel, record data and respond automatically to changes in field conditions. It is already assembled, which provides a lot of benefits in terms of safety. At present, pieces of pipe and equipment are put together manually by technicians in different configurations every time. The AWT is skid mounted, and is simply hooked up.”

Driving job performance by the integration of digital technologies

The AWT is advancing the market by providing clients an already assembled solution, which streamlines efficiencies and delivers a quicker path to first oil.

“By leveraging UCOS, we are able to not only automate and reduce the human intervention required to perform this service, we are also providing insights to our field personnel that were never possible before,” says Zachary Curry, product line manager with Global Controls and Automation, Surface Technologies.

“We can now hand the technicians a tablet and they are able to see how the equipment is performing, the overall job progress and if issues arise, we provide them tools for troubleshooting, reducing any nonproductive time that is typical in these types of operations,” Curry says.

AWT is a big step forward, says Ryan Malone, global senior systems engineer and product development lead for Surface Technologies.

The AWT utilizes product components from various business units within TechnipFMC. The result is a highly efficient, zero emission, compact skid solution, which is safely monitored by technicians outside of the danger zone, and fully serviced by TechnipFMC field technicians. With the improved separator internals and controls the unit can process drier oil and gas and avoid wasteful hydrocarbon losses.

“It means the quality of the oil separated by the vessel is a lot better than before,” Malone says. “By having visibility of the data, we can make decisions and necessary adjustments.”

Integrated intelligence

AWT is another step towards TechnipFMC’s service integration and digitalization capabilities. It seamlessly leverages a broad range of our product portfolio. It uses our proven distributed control systems UCOS, which not only provides the local automation and controls but also creates a secure and robust communication channel to the cloud where the more advanced analytics and analysis take place.

TechnipFMC is delivering not only true distributed control system (DCS) functionality, including fully redundant architecture and software-based controls, but is able to further integrate modern technologies like machine learning to help drive enhanced decision-making capabilities at the edge. This supports a truly integrated and intelligent solution that drives workforce efficiency and productivity and a better client experience.

Continuous Improvement

Through the use of our integrated, software driven digital technologies, TechnipFMC is able to continuously improve on the performance of our assets with little more than a software update, ensuring superior quality and productivity for our clients.

“The unconventional shale business is continually improving,” Anzola says. “Digital technology has brought down the break-even price, and there will be more advances to come in well completions including flowback. Our AWT will help with that.”

石油圈

石油圈